选择质量。选择可靠性。选择原创。

使用我们经过认证的赛科原装零配件,保护您的设备并确保达到最佳性能。

选择正确的备件对于确保贵重机械设备的性能和使用寿命至关重要。市场上的备件种类繁多,但并非所有备件都能满足您的设备所需的高标准。原装零配件与您的机器要求精确匹配,可确保可靠运行和最高效率。

原装零配件为何重要

在维护和修理您的贵重设备时,没有任何妥协的余地。我们的原始设备制造商 (OEM) 零件所提供的不仅仅是您所需要的功能,它们还能确保您设备的性能、可靠性和使用寿命。

与此相反,假冒或非原装零件会带来巨大风险,从性能下降到严重损坏。

性能和可靠性:

- 与您的机器精确匹配

- 由原始设备制造商设计和测试

- 最佳性能和更长的使用寿命

- 降低故障和停机风险

假冒部件的风险:

- 未经严格控制而降低质量

- 降低性能,增加磨损

- 潜在损坏和故障导致的高成本

- 安全和操作风险

保修和支持:

- 保留全部保修权利

- 获得技术支持和服务

- 长期投资保证

如何识别赛科原装零配件

为确保您的设备只收到高质量的正品零配件,了解正品零配件的特征非常重要。

四个安全特征

我们的原装零配件包装具有特殊的安全特征,可确认其真实性。这些特征旨在让您放心使用原装零配件。

Packaging

Our packaging is the first indication to help you distinguish genuine parts from counterfeits. It includes special features such as clearly marked labels that ensure authenticity and protect the quality and performance of your equipment.

Four Security Features

Our Original Spare Parts packagings have special security features that confirm their authenticity. These features are designed to give you peace of mind that you are using genuine parts.

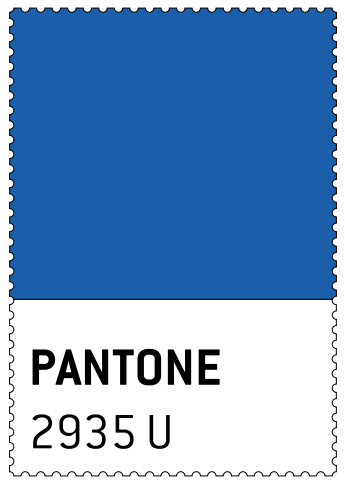

颜色

原包装为强烈、动感的蓝色,具有强烈的存在感。

标识图案

每个品牌都有自己的品牌包装,包装上印有相关徽标的图案。

赛科品牌

在每个包装的右上角,您会发现一个附加说明,表明该品牌属于母公司赛科。

原始密封

开盖上的封条表明每个包装均为原装零配件。该封条也是您的保修证明。

Centrifugal Pumps

The following example shows how impellers from third-party manufacturers differ from our original parts – and what effects these differences have on your machines.

Left: counterfeit impeller - much simpler material and no milled grooves for balancing.

Right: original impeller - good quality and with milled grooves.

Original impeller

Good casting quality. Thin blades and with balancing holes to reduce axial forces.

Counterfeit impeller

Due to the significantly smaller distance in the blade channel and sharp leading edges due to machining, the flow velocity will increase, the local pressure will decrease and thus the NPSH value will increase exponentially.

At low inlet pressure (which is usually the case with seawater pumps), the flow rate of the pump probably collapses. With sufficient inlet pressure, however, cavitation erosion increases significantly. The lifetime of the impeller is reduced.

Original impeller with correct channel cross-section.

Counterfeit impeller with too small cross-section.

Counterfeit impeller

The balancing holes are not drilled through.

Original impeller

The balancing holes are drilled correctly.

- The thicker and rougher blades have a significantly negative influence on all hydraulic parameters. It also looks as if the blade angles at the inlet are smaller than in the original.

- The delivery head becomes significantly smaller and flow rate increases.

→ Steep characteristic curve. The efficiency will be significantly lower. - The significantly smaller distance in the blade channel cross sections, and sharp leading edges due to machining, the flow velocity will increase, the local pressure will decrease and thus the NPSH value will increase exponentially.

At low inlet pressure (which is usually the case with seawater pumps), the flow rate of the pump probably collapses. With sufficient inlet pressure, however, cavitation erosion increases significantly. The lifetime of the impeller is reduced. - The balancing holes are not drilled through, so there is no effect. This significantly increases the axial thrust, which reduces the bearing lifetime. In extreme cases, the ball bearings may overheat, the grease leaks out and the bearings are destroyed after a very short time.

- No balancing → higher axial forces → higher vibration → reduced bearing lifetime.

- The trailing edge is straight and not angled. This causes higher pressure fluctuations when the trailing edge of the impeller passes the spiral tongue.

→ Higher noise and vibration.

您知道吗?

OEM 是 "原始设备制造商 "的缩写,这意味着这些零件是由您设备的原始制造商直接制造的。这些原装零件经过专门设计,可满足您设备的严格质量标准和技术要求。

但要注意:

市场上有些供应商滥用 "OEM "一词,将其劣质产品冒充为 "原装等效制造商"。这种欺骗行为可能会造成混淆,并使您有可能收到劣质零件,而这些零件的性能和使用寿命与真正的 OEM 零件并不相同。

了解原装正品和假冒伪劣产品之间的主要区别有助于您为设备选择最佳质量的产品。请注意更换部件的来源和真实性,以确保设备的长期性能。