Oil & Gas Solutions

Ensuring operational reliability, improved energy efficiency, and reduced environmental impact.

THE GLOBAL DEMAND for crude oil challenges the world economy as well as the facility managers of production, transportation, storage, and refining operations. CIRCOR understands the pressures you face. The remote locations, extreme climates and limited people resources of onshore and offshore production facilities. The downstream production commitments and erratic rail tank car schedules in transport. The shifting needs of varied inventory that must be turned around quickly in storage facilities. The escalating number of environmental regulations and significant power needs in refineries. Customers turn to CIRCOR for fluid-handling solutions that transfer critical fluids without interruption and keep equipment running at peak efficiency. Because failure is not an option in oil & gas.

CIRCOR tackles tough challenges in four distinct oil & gas applications: exploration & production, transportation, storage, and refinery & petrochemical. Our expert team of oil industry engineers and technicians work with you to deliver the right solutions for your unique fluid handling needs. In fact, CIRCOR’s trusted brands – Allweiler®, Imo®, Houttuin™, Tapco Enpro, Delta Valve, Tushaco®, RTK®, Schroedahl®, Warren® and Zenith® – help move more than 4.5 million barrels of crude every day, with our unique ability to deliver:

- A portfolio of rotary PD pumps that outperform traditional centrifugal pumps in these applications along multiple metrics

- Critical pump and valve application expertise, encompassing deep design and process knowledge, industry thought leadership and years of experience and proven successes in the field.

- A global network of associates, distributors and service technicians ready to provide start-up assistance, training, analysis, troubleshooting and repair wherever and whenever you need us.

CIRCOR Advantage: Ensured operational reliability, improved energy efficiency, and reduced environmental impact.

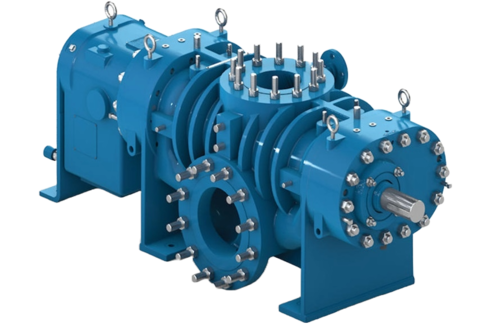

Highly efficient and built to last, these heavy-duty, high pressure pumps deliver efficient performance year after year and are perfectly suited for a wide range of applications in the oil and gas industry.

1,400

Max. Flow Rate [GPM] :4,500

Max. Viscosity [mm²/s] :100,000

Max. Fluid Temperature [°F] :225

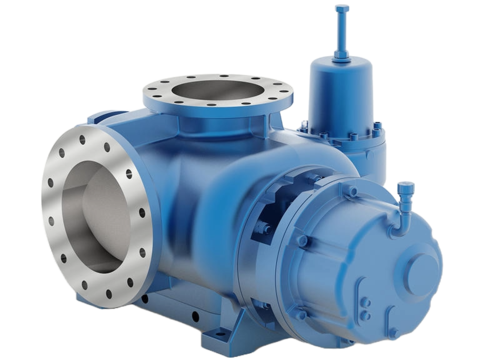

Optimized for dry running, stripping and self-priming to ensure low NPSH requirements. In addition, low, medium and high pressure versions are available and the pumps are available for CIP.

5.000

Max. Diff. Pressure [bar] :60

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

MFG in Monroe, NC USA

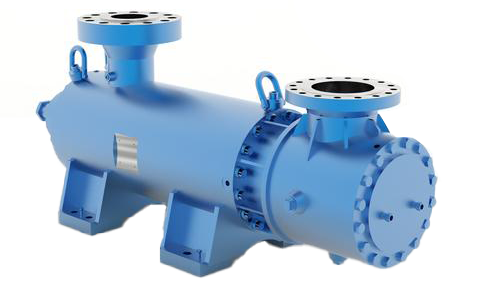

IMO 8L series pumps are designed for pipeline transport in medium to high pressure service on crude oils, fuel oils and other petroleum products.

2,000

Max. Flow Rate [GPM] :2,900

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :225