A History of Performance

A past, present and future propelled by growth.

For over 160 years, the Allweiler name has been synonymous with comprehensive and unrivaled

pump expertise – with an equally comprehensive product portfolio.

In 1860, Gotthard Allweiler invented the fire-fighting wing pump, filling a market gap. Nearly 160 years later, Allweiler’s pioneering spirit lives on at CIRCOR. Our history is rich with technological, design and production innovations that shape modern progress and align with market needs for fluid-handling solutions around the world.

Today’s Allweiler customers benefit from the specialized pump knowledge that spans generations. Regardless of their pumped medium, they can confidently source the most suitable pump or system to handle it. That is because Allweiler pumps are precisely tailored to each industry-specific application and conform to the most stringent quality and reliability standards governing them. Unmatched reliability and efficiency of every pump is the goal of Allweiler’s accredited quality assurance system.

From establishing a company-owned foundry producing high-quality castings of materials available only through Allweiler, to achieving global leadership in both centrifugal and positive-displacement pump technology, we have delivered high technical and economic value to customers while reducing their total cost of ownership of valuable assets, decade after decade.

IMO and Houttuin have long been part of our product portfolio as independent brands. Since 2025, they officially form product brands under Allweiler, bringing their specialized screw and twin-screw pump technologies fully into the Allweiler family and further expanding the range of solutions we can offer our customers.

Now, as part of a family of time-tested CIRCOR industrial brands, Allweiler is bolstered by operating synergies and international sales structures that make the company more flexible and customer-centric than ever before. To our many customers active worldwide, we are pleased to offer all needed resources wherever their opportunities may take them. Our broad product range is augmented by personal, competent advice on-site and comprehensive service after the sale. CIRCOR speaks the languages of its customers and understands their business and regulatory requirements.

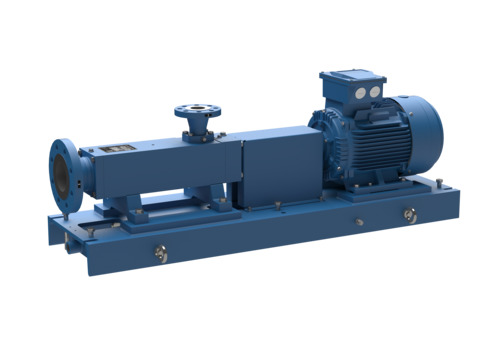

Three-screw pump series for lubricating oil applications. For lubricating oil applications according to API 676, optionally with mechanical sealing according to API 682 and pressures up to 20 bar.

880

Max. Outlet Pressure [bar] :20

Max. Fluid Temperature [°C] :100

Viscosity Range [mm²/s] :5-750

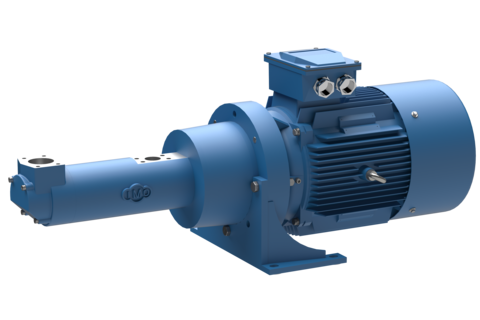

Based on the latest technology and are ideally suited for use in hydraulic applications up to 250 bar. Known for their exceptional reliability, maintaining productivity and minimizing downtime.

1.050

Max. Inlet Pressure [bar] :10

Max. Outlet Pressure [bar] :250

Max. Fluid Temperature [°C] :155

Viscosity Range [mm²/s] :1,6-400

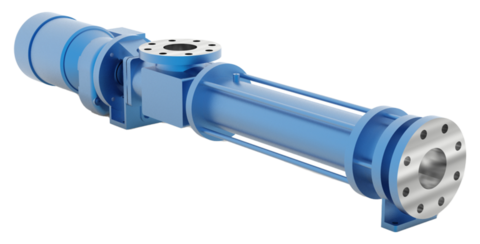

Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR). Suitable for a wide range of fluids.

1.600

Max. Discharge Pressure [bar] :10

Max. Fluid Temperature [°C] :100

Max. Viscosity [mm²/s] :190.000

For the demanding requirements of the oil and gas industry under changing operating conditions. These compact, rugged pumps are designed for stand-alone operation in remote oil fields.

5.000

Max. Diff. Pressure [bar] :60

Max. Fluid Temperature [°C] :120

Viscosity Range [cSt] :0,5 - 100.000

AFTERMARKET

Your best resource for service, maintenance and quality parts.

No one knows your valves, pumps and systems like the experts at CIRCOR. Our certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry. We have the resources to troubleshoot, analyze and solve even your most complex issues in ways other service options are unable to.

CIRCOR’S German entity Allweiler GmbH received big pump order to be installed in Bilfinger Engineering & Technologies' (BET) Exhaust Gas Cleaning System for Ships.

In shipbuilding, most large vessels that are susceptible to heeling could benefit from an anti-heeling system (heeling is the term for when a ship tilts on any of its sides). The most common cause of heeling is uneven cargo loading/unloading in port, but high winds, waves, currents and turns can also cause it. Heeling can be dangerous to ships and to their passengers and cargo, so a good anti-heeling system can not only make port operations simpler, it can also make a ship safer in general.

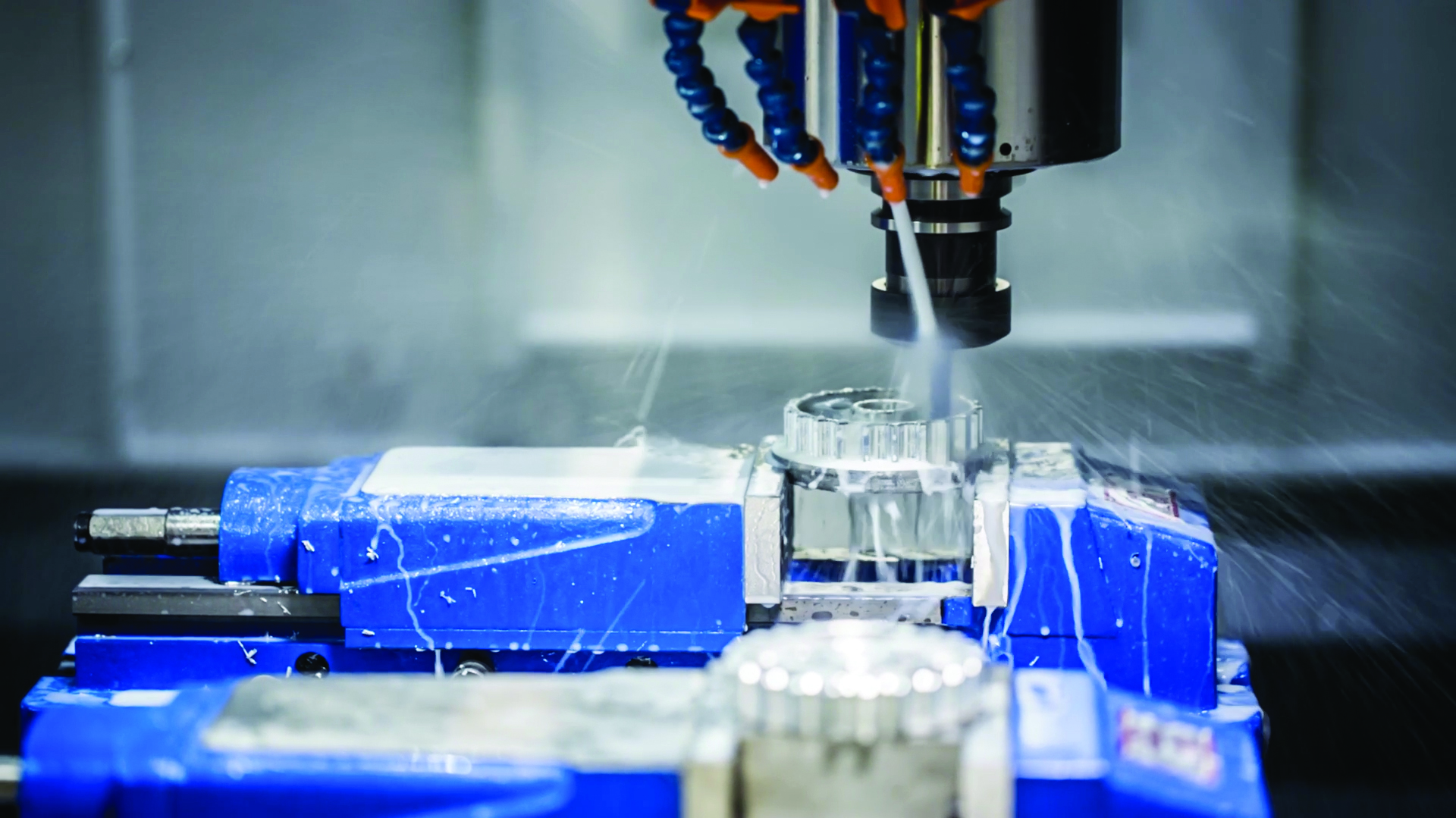

EMTEC-C three-screw pumps excel at moving chips and particles away from cutting surfaces both precisely and efficiently. And with its incredibly durable construction, it's a level of performance that will stand up to even the harshest environments.

In tunnel construction, excavation occurs two ways depending on geologic conditions at the site: by conventional drill-and-blast and by precision-operated “mills in the mountain” known as tunnel boring machines, or TBMs. The Brenner Base Tunnel through the Alps, destined to become the longest underground railway connection in the world at a planned length of 64 kilometers, is being excavated using TBMs supplied by Herrenknecht of Schwanau, Germany

Photo: Copyright © BBT SE

Allweiler Service Portal

For our registered customers and partners we provide important technical information, documents and services in our Allweiler Service Portal around the clock.

PUMP RECYCLING

Sustainable and environmentally friendly pump return

Our service in Germany and UK does not stop after the pump has reached the end of its operating life. Since pumps count as electronic waste, they must be handed in at certified collection points according to law. We support you in this process. You can return the old pumps we produced to us free of charge and we will take care of the recycling process.

Read more about the most important requirements for handling electrical and electronic equipment:

Contact

We are here for you! Contact our team of experts for advice, technical information or customised solutions.

Contact Form

If you have any questions, praise, constructive criticism, or suggestions for improving our products or services, please do not hesitate to contact us.

Sales Partner

Our worldwide network of sales partners ensures that you always have the right contact in your region.

24/7 Service Hotline

Our 24/7 service hotline ensures that you can reach the right expert anytime:

+49 173 561 16 56