Centrifugal Pump Technology

Learn everything you want to know about the popular technology.

Definition

What are Centrifugal Pumps?

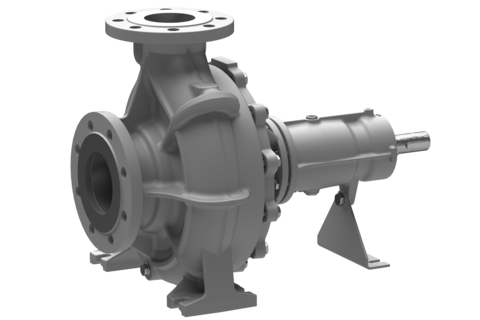

Centrifugal pumps are hydrodynamic machines used to move liquids efficiently. This makes them indispensable machines in many industries. Centrifugal pumps can handle large volumes of fluids and can move an impressive range of fluids - from corrosive and abrasive to hot, cold, viscous or contaminated. Their versatility and adaptability make centrifugal pumps ideal for integration into many applications.

Whether in water supply, marine applications or chemical processes, they can be optimally designed. Their simple and robust technology makes them not only extremely reliable, but also extremely durable. Features that make centrifugal pumps the most widely used pumping technology in the world.

Cost-Effective

Rugged Design

Work Efficiently With Water-Like Fluids

Flexible

Technology

How do Centrifugal Pumps work?

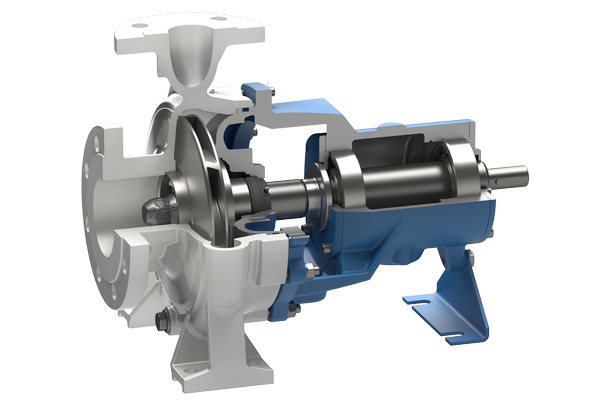

In radial centrifugal pumps, the fluid is delivered and the pressure increase is brought about in a rotating impeller with vanes. This impeller is driven by a drive motor via a shaft and transfers mechanical energy to the pumped fluid continuously flowing through the impeller. The liquid enters the impeller axially and is accelerated from the inside to the outside by the effect of centrifugal force. This results in a transfer of energy into pressure and velocity energy. At the outlet of the impeller, the liquid enters the volute casing where the flow velocity is again slightly reduced. As a result of further energy conversion, the pressure increases. Through the volute, the liquid is directed to the pump outlet.

Watch the video to see how centrifugal pumps work.

Benefits

Advantages of Centrifugal Pump Technology

Centrifugal pump technology is an integral part of many industries. Due to their simple design, operating efficiency and wide range of applications, centrifugal pumps are often the preferred pump type. Below are some of the key benefits that make centrifugal pump technology the first choice.

Centrifugal pumps are easy to maintain and repair, saving time and money. Their robust design, which is less prone to failure, minimizes maintenance costs and ensures reliable operation.

Centrifugal pumps are highly efficient at handling water-like fluids, whether hot or cold, neutral or aggressive, clean or contaminated. As a result, they can be used in a wide range of applications.

Centrifugal pumps are characterized by their remarkable versatility. They can be used in various applications such as water supply, chemical industry or maritime sector. They can also be adapted to specific processes. This includes the selection of suitable materials, the design for optimal installation or the appropriate shaft seal for the process fluid. This adaptability makes them a highly flexible solution.

Support

How to choose the right Centrifugal Pump

Choosing the right centrifugal pump requires experience, as a large number of application-specific factors determine the optimum pump design. Important criteria include the operating data, the nature of the pumped medium, the desired type of installation and compliance with specified standards or regulations. All these aspects influence the selection of pumps as well as their specific design features.

Our team of experts help to make the right choice.

We will work with you to review your application and determine which pump meets your needs best.

Trusted Brand

Centrifugal Pumps from ALLWEILER

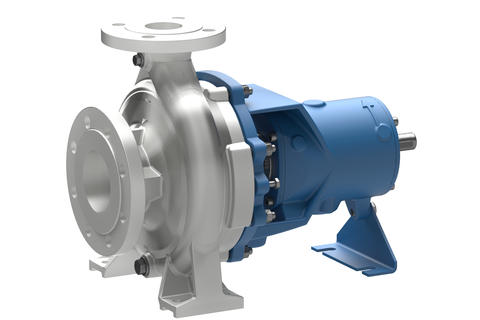

Our pumps are characterized by the highest quality and reliability. As a renowned manufacturer, we are constantly optimizing our pump portfolio. We use the latest development technologies and methods to ensure pumps with a long service life and reliable performance. In demanding industrial or marine environments, our pumps ensure reliable fluid transport in your system. With a wide range of models and configuration options, we offer customized solutions for a variety of applications. Benefit from Allweiler's high quality pumps that guarantee you optimum efficiency and reliability.

Discover our wide range of centrifugal pumps today and optimize your fluid transfer.

Used in a wide variety of processes in the chemical and process industries. They are also indispensable in other industries when it comes to safely and efficiently pumping aggressive or corrosive, hot or cold, clean or solids-laden media.

1.200

Max. Delivery Head [m] :147

Max. Outlet Pressure [bar] :25

Max. Fluid Temperature [°C] :350

Designed for safe and reliable pumping of heat transfer fluids - whether your heat transfer fluid is organic mineral oil-based, synthetic heat transfer oil up to 400 °C, or hot water up to 207 °C.

1.450

Max. Delivery Head [m] :100

Max. Outlet Pressure [bar] :25

Max. Fluid Temperature [°C] :400

Designed to meet the high demands of the marine and offshore industry, but are also optimized for installation in the confined spaces of ship engine rooms. With efficient pump hydraulics specifically tailored to the needs of the marine and offshore industries

2.400

Max. Delivery Head [m] :155

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :140

Used in heat transfer systems to circulate organic heat transfer oils (also called thermal oil) up to 350 °C. They offer an optimal combination of safety, efficiency and durable design to meet the requirements of demanding industrial processes.

2.300

Max. Delivery Head [m] :145

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :350