Emergency Pumps

Aftermarket Service | Industrial | Germany

Get ready for quicker and more reliable solutions with our new emergency pumps in Radolfzell, Germany.

Reduced Downtime, No Compromises

Emergency Pumps

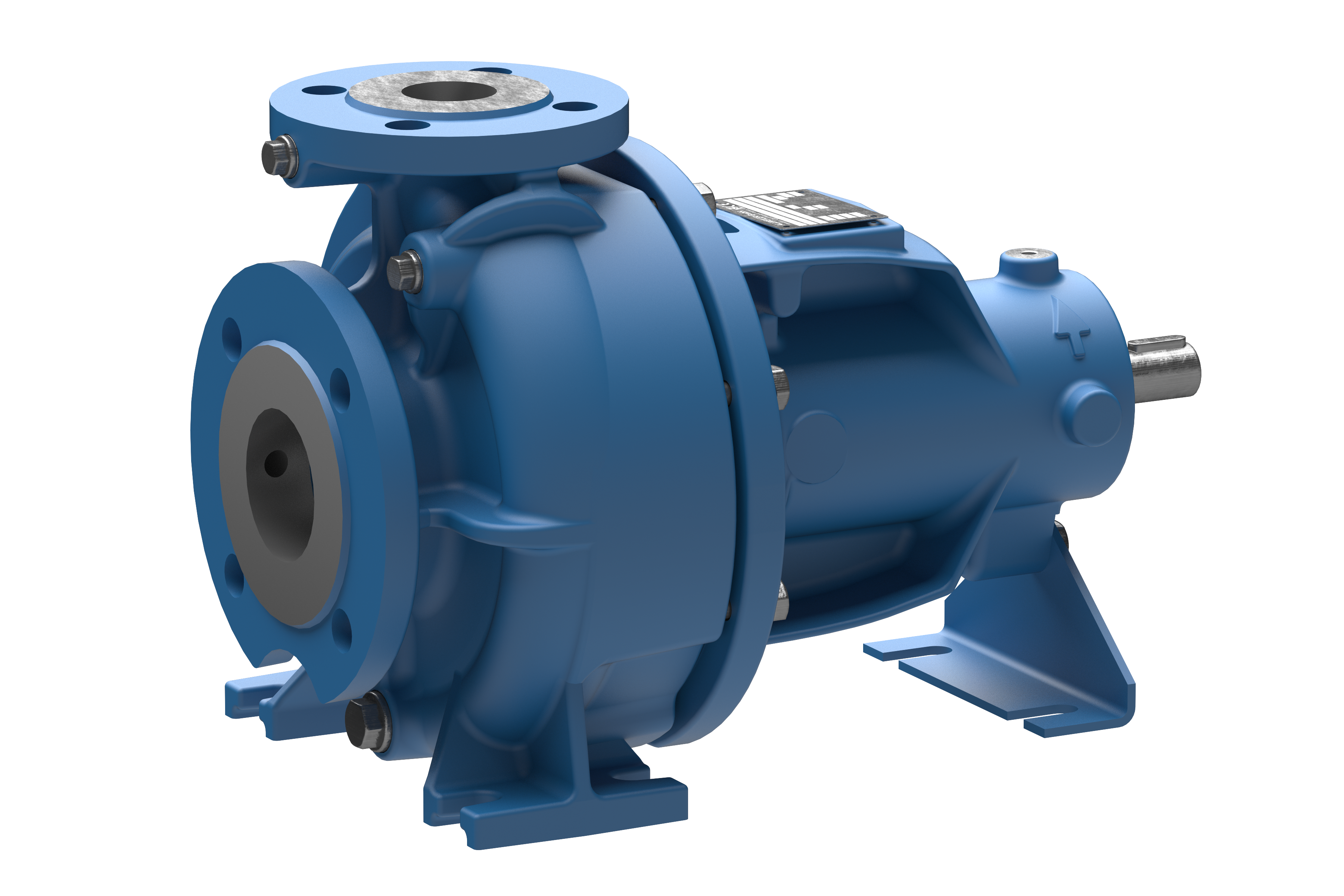

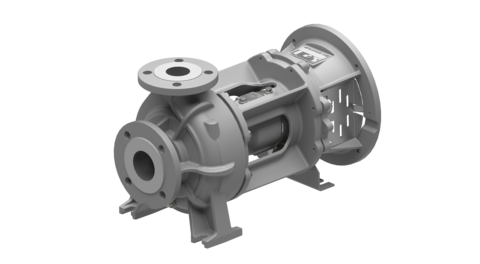

Accelerate your operational efficiency with our new emergency centrifugal pumps.

Designed for versatility, these pumps are suitable for a wide range of industrial applications. With a tailormade pumps in as little as 2 business days*, our service ensures minimal disruption to your operations. Keep your operations running smoothly and effectively reduce downtime with our reliable pump solutions.

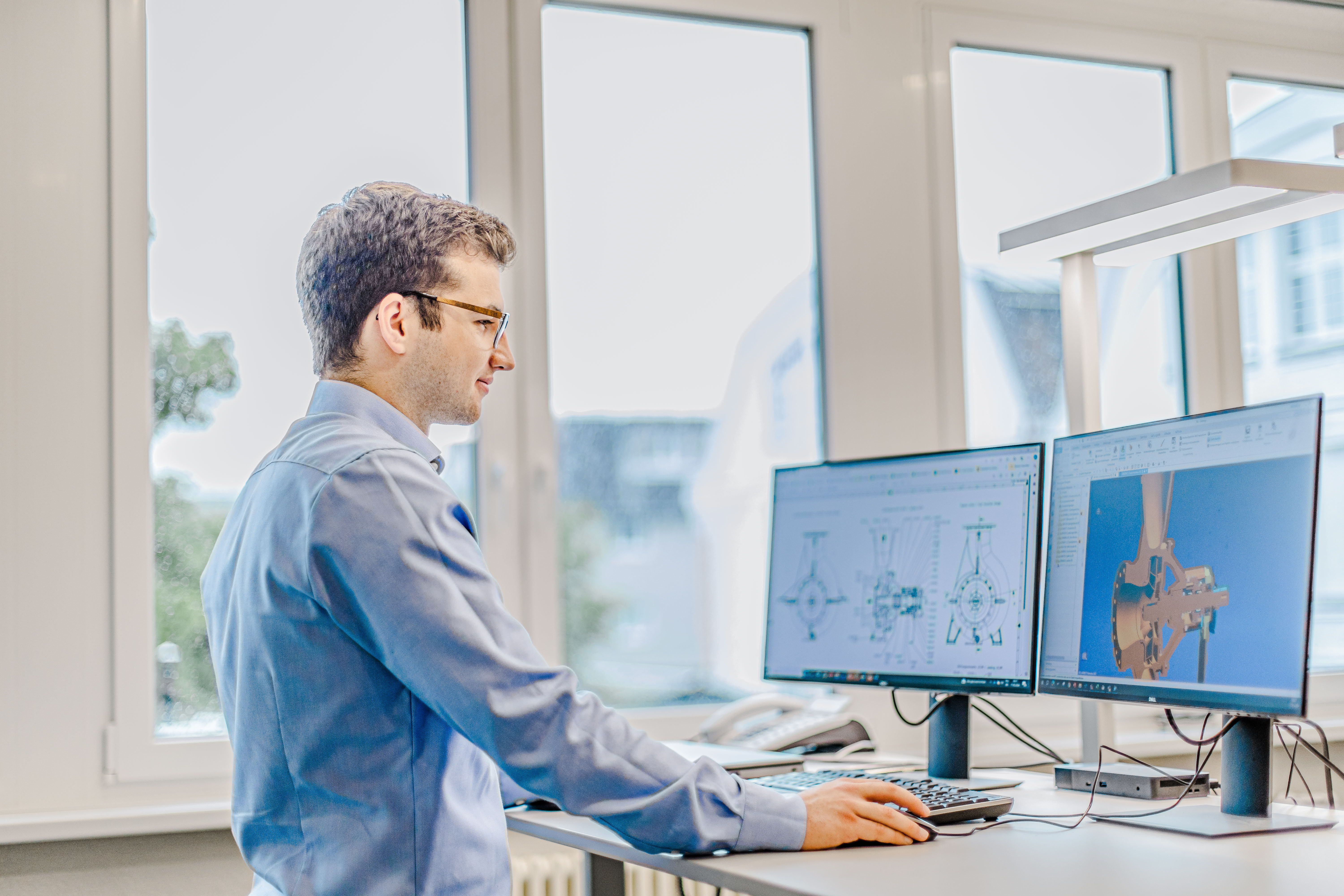

Custom-made pumps in Radolfzell

Our Radolfzell facility offers custom pump manufacturing for special requirements upon request. Each pump is built to your exact specifications and ready for shipment within 2 business days. This customized service ensures that your systems receive the precise pump needed for optimal performance, with minimal disruption and maximum uptime.

You need an immediate replacement pump?

Our emergency number for even quicker support:

+49 173 561 16 56

CALL US NOW

Wide Range

We will commence with 60 of the most commonly used ALLWEILER centrifugal pump types, ensuring you have the right pump for every need.

Fast Delivery

We promise to prepare your order for delivery within 2 business days, reducing downtime and allowing you to resume your

operations quickly.

Quality Assurance

Our pumps are made to the best quality standards, providing performance in even the most demanding situations.

Individual Solutions

We know your operational needs are unique. Our skilled teams are pleased to adjust the pump to fit seamlessly into your system.

What sets us apart

Custom-made Pumps Within 2 Business Days

Ensure uptime in emergency situations with our readily available centrifugal pumps. These pumps will be prepared for you and can be shipped within two business days, providing a reliable solution when you need it most. Contact our team to be prepared for any emergency.

Available sizes: 20-160 to 80-160

*To meet your custom made operational needs and fastest delivery, an expediting fee of 30 % will be added

Your needs matter

Durable Solutions

Our Radolfzell facility offers high-performance pumps that, while available in standard versions, can be quickly customized to meet your specific needs. Understanding the unique nature of your operation, our experts are ready to customize each pump to meet your exact needs.

Our Emergency Pumps aren't just a replacement. They are made to last!

Designed to maintain the seamless operation of your systems, these pumps ensure no compromise on quality or efficiency. Crafted on request and ready for delivery within 2 business days, they offer a dependable and permanent resolution for your operational needs.

Handle high-temperature fluids with confidence with Allweiler's Allheat Series pumps. Designed for extreme thermal conditions, these pumps offer exceptional resistance to high temperatures and ensure safe, efficient operation. Ideal for critical industrial applications, they are custom-built in Radolfzell, Germany, and can be shipped in 2 business days.

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

|---|---|---|---|---|

| NTWH | 25-160 | 12 | U3.3A-K1 | W141 |

| 25-200 | 2 | U2.11A-S1 | ||

| 32-160 | 2 | |||

| 32-200 | 1 | |||

| 40-160 | 2 | |||

| 40-200 | 1 | |||

| 40-250 | 1 | |||

| 50-160 | 1 | |||

| 50-200 | 1 | |||

| 50-250 | 1 | |||

| 65-160 | 1 | |||

| 65-200 | 2 | |||

| 80-160 | 1 |

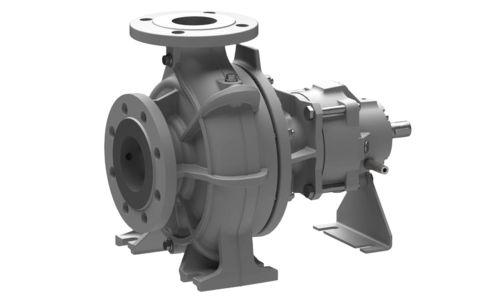

Experience the rugged and durable design of Allweiler's NTT pump family. Engineered for high performance and efficiency, these pumps are perfect for demanding environments where reliability is critical. They are available for quick customization and can be shipped from Radolfzell in 2 business days to keep your operations running smoothly.

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

Motor Size (two shaft) |

|---|---|---|---|---|---|

| NBT | 25-160 | 12 | U5A | W4 | 80 |

| 25-200 | 2 | 90S | |||

| 32-160 | 2 | 90L | |||

| 32-200 | 1 | 100L | |||

| 40-160 | 2 | 112M | |||

| 40-200 | 1 | 132S | |||

| 40-250 | 1 | 132M | |||

| 50-160 | 1 | 160M | |||

| 50-200 | 1 | 160L | |||

| 50-250 | 1 | 180M | |||

| 65-160 | 1 | 200L | |||

| 65-200 | 2 | ||||

| 80-160 | 1 |

| Series | Size | Hydraulic |

Shaft |

Material Design |

Motor Size (two shaft) |

|---|---|---|---|---|---|

| NIT | 25-200 | 22 | U5A | W4 | 80 |

| 32-160 | 22 | 90S | |||

| 32-200 | 1 | 90L | |||

| 40-160 | 22 | 100L | |||

| 40-200 | 1 | 112M | |||

| 40-250 | 1 | 132S | |||

| 50-160 | 24 | 132M | |||

| 50-200 | 1 | 160M | |||

| 50-250 | 1 | 160L | |||

| 65-160 | 1 | 180M | |||

| 65-200 | 23 | 200L | |||

| 80-160 | 1 |

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

|---|---|---|---|---|

| NTT | 25-160 | 12 | U5A | W4 |

| 25-200 | 2 | |||

| 32-160 | 2 | |||

| 32-200 | 1 | |||

| 40-160 | 2 | |||

| 40-200 | 1 | |||

| 40-250 | 1 | |||

| 50-160 | 1 | |||

| 50-200 | 1 | |||

| 50-250 | 1 | |||

| 65-160 | 1 | |||

| 65-200 | 2 | |||

| 80-160 | 1 |

Optimize your industrial processes with Allweiler's versatile NT pump family. Known for their adaptability, these pumps can handle a wide range of fluids and operating conditions. Customized to your specific needs, they are shipped from Radolfzell within 2 business days, ensuring reliable performance in a variety of applications.

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

Motor Size (two- phase) |

|---|---|---|---|---|---|

| NB | 20-160 | 1 | U3.30D | W135 | 80 |

| 25-160 | 12 | U3.40D | 90S | ||

| 25-200 | 2 | U3.50D | 90L | ||

| 32-125 | 2 | U3.51D | 100L | ||

| 32-160 | 2 | 112M | |||

| 32-200 | 1 | 132S | |||

| 40-125 | 1 | 132M | |||

| 40-160 | 2 | 160M | |||

| 40-200 | 1 | 160L | |||

| 40-250 | 1 | 180M | |||

| 50-125 | 2 | 200L | |||

| 50-160 | 1 | ||||

| 50-200 | 1 | ||||

| 50-250 | 1 | ||||

| 65-125 | 2 | ||||

| 65-160 | 1 | ||||

| 65-200 | 2 | ||||

| 80-160 | 1 |

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

Motor Size (two- phase) |

|---|---|---|---|---|---|

| NI | 20-160 | 1 | U3.30D | W135 | 80 |

| 25-200 | 22 | U3.40D | 90S | ||

| 32-125 | 22 | U3.50D | 90L | ||

| 32-160 | 22 | U3.51D | 100L | ||

| 32-200 | 1 | 112M | |||

| 40-125 | 1 | 132S | |||

| 40-160 | 22 | 132M | |||

| 40-200 | 1 | 160M | |||

| 40-250 | 1 | 160L | |||

| 50-125 | 22 | 180M | |||

| 50-160 | 24 | 200L | |||

| 50-200 | 1 | ||||

| 50-250 | 1 | ||||

| 65-125 | 22 | ||||

| 65-160 | 1 | ||||

| 65-200 | 23 | ||||

| 80-160 | 1 |

| Series | Size | Hydraulic | Shaft Seal |

Material Design |

|---|---|---|---|---|

| NT | 25-160 | 12 | U3.30D | W10 |

| 25-200 | 2 | U3.40D | W135 | |

| 32-160 | 2 | U3.50D | ||

| 32-200 | 1 | U3.51D | ||

| 40-160 | 2 | |||

| 40-200 | 1 | |||

| 40-250 | 1 | |||

| 50-160 | 1 | |||

| 50-200 | 1 | |||

| 50-250 | 1 | |||

| 65-160 | 1 | |||

| 65-200 | 2 | |||

| 80-160 | 1 |