NTT-Family

Efficient Heat Circulation for Industrial Excellence

Our NTT pump family is used in heat transfer systems to circulate organic heat transfer oils (also called thermal oil) up to 350 °C to efficiently transport centrally generated heat to its heat consumers. The centrifugal pumps offer an optimal combination of safety, efficiency and durable design to meet the requirements of demanding industrial processes.

NTT centrifugal pumps feature a robust, application-optimized design. The proven design solution offers our customers high operational reliability at comparatively low investment costs. This means you can rely on reliable pump technology that delivers high performance even under the most demanding conditions.

Reliable & Safe

Tens of thousands of proven bearing

and sealing concept for heat transfer oils

Cost-Efficient

Thanks to simple design principle

Versatility

3 types of construction (base plate, block, inline)

for optimum installation in the system

We know that pumping hot fluids can be challenging. You can overcome it with NTT centrifugal pumps designed specifically for pumping mineral oil-based organic heat transfer fluids. The special pump design with an effective thermal barrier effectively reduces the temperature at the seal and in the fluid leakage.

The high mechanical stiffness of the pump between the casing and the bearing bracket ensures high operational reliability and long wear part life. Other safety features, such as a packing behind the impeller, effectively minimize leakage in the event of a shaft seal malfunction. Decisive advantages for the safety of your plant.

Easy Maintenance

Special Bearing & Sealing Design

Pumps of our NTT family do not require external liquid cooling of the shaft seal despite high operating temperatures. This not only reduces operating costs, but also eliminates the need for additional cooling equipment. In addition, the use of a shaft seal allows for easy maintenance of the centrifugal pumps and provides long-term cost savings by eliminating the need for specialized sealing systems.

Another aspect of NTT's ease of maintenance is the use of standard wear parts, such as the two roller bearings. These wear parts are available worldwide and allow efficient maintenance of your pump.

Optimal Integration

NTT Pumps for Efficient Installation

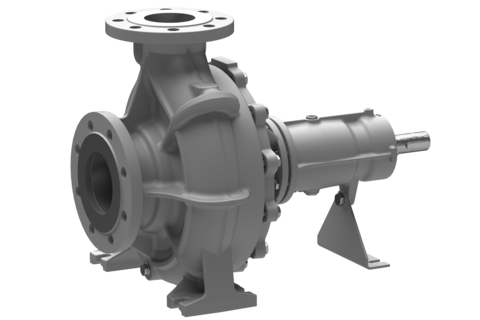

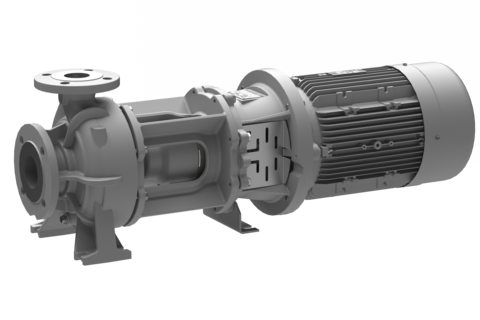

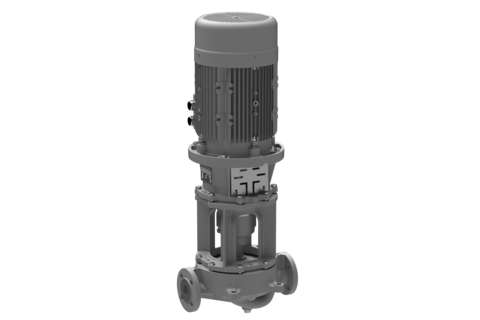

We understand that heat transfer equipment is used in a wide variety of systems. For optimal integration of the pump into your system, we offer three variants. In addition to the horizontally installed NTT series, where the pump and drive motor are coupled on a common baseplate, we also offer the close-coupled NBT and NIT in-line pump series, which can be installed horizontally or vertically and are ideal for limited installation space.

| Series | Specifications | Max. Capacity [m³/h] |

Max. Delivery Head [m] |

Max. Outlet Pressure [bar] |

Max. Fluid Temperature [°C] |

|---|---|---|---|---|---|

| NTT | Process design installation dimensions according to DIN EN 733 |

1,250 | 145 | 16 | 350 |

| NBT |

Block design acc. to DIN EN 733 |

270 | 145 | 16 | 350 |

| NIT |

Inline design |

220 | 145 | 16 | 350 |