Product Search

Real-world sizing and selection tool for a variety of the most popular pumps across the CIRCOR portfolio.

Search

Self-priming three-screw pump for hydraulic applications with pressures up to 120 bar. Robust design, with hardened and polished spindles and fully balanced axial thrust.

880

Max. Outlet Pressure [bar] :120

Max. Fluid Temperature [°C] :100

Viscosity Range [mm²/s] :3-760

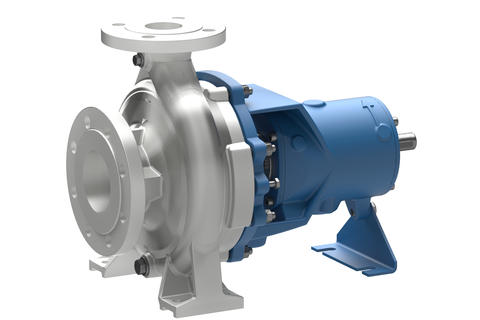

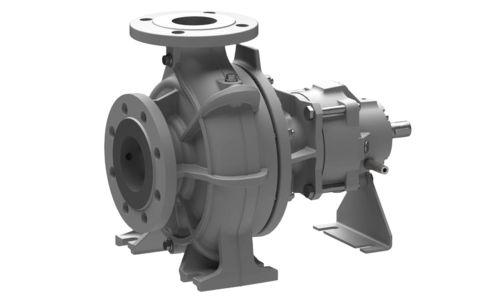

Used in a wide variety of processes in the chemical and process industries. They are also indispensable in other industries when it comes to safely and efficiently pumping aggressive or corrosive, hot or cold, clean or solids-laden media.

1.200

Max. Delivery Head [m] :147

Max. Outlet Pressure [bar] :25

Max. Fluid Temperature [°C] :350

Designed to meet the high demands of the marine and offshore industry, but are also optimized for installation in the confined spaces of ship engine rooms. With efficient pump hydraulics specifically tailored to the needs of the marine and offshore industries

2.400

Max. Delivery Head [m] :155

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :140

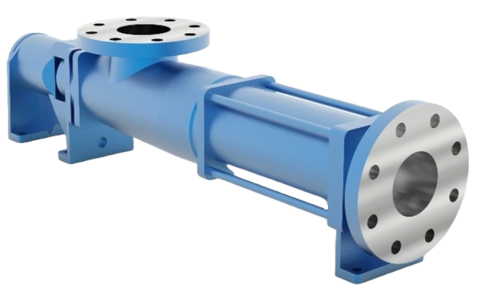

Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR). Suitable for a wide range of fluids.

1.600

Max. Discharge Pressure [bar] :10

Max. Fluid Temperature [°C] :100

Max. Viscosity [mm²/s] :190.000

The solution when it comes to size reduction of solids. They offer unsurpassed performance and efficiency when processing abrasive media, corrosive liquids and solids.

160

Max. Delivery Head [m] :3,0

Max. Fluid Temperature [°C] :80

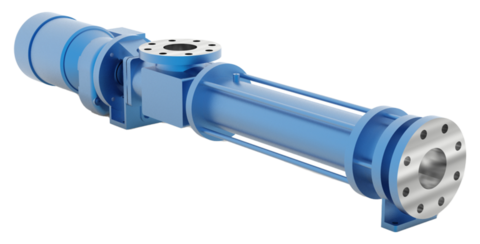

Powerful, but also extremely versatile pump series. Whether thinor highly viscous liquids, neutral or aggressive media, gaseous or foaming liquids – our pumps effortlessly master every challenge.

12.000

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :250.000

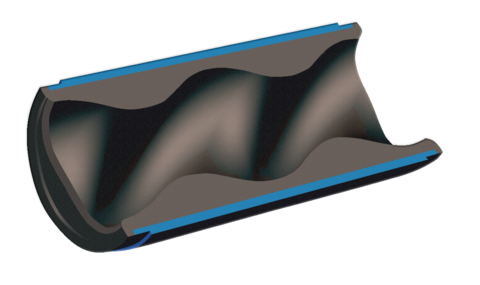

Specifically developed for our progressing cavity pumps with a clear focus on cost effectiveness. The compound formulation is the key to how long a stator will maintain its original flow rate.

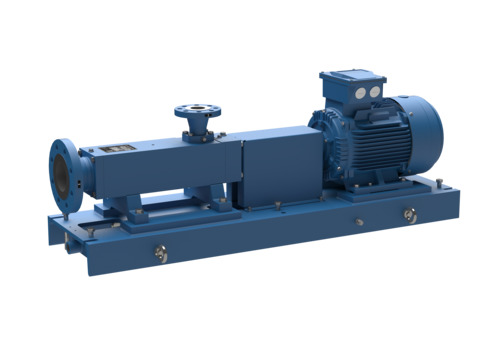

Designed for safe and reliable pumping of heat transfer fluids - whether your heat transfer fluid is organic mineral oil-based, synthetic heat transfer oil up to 400 °C, or hot water up to 207 °C.

1.450

Max. Delivery Head [m] :100

Max. Outlet Pressure [bar] :25

Max. Fluid Temperature [°C] :400

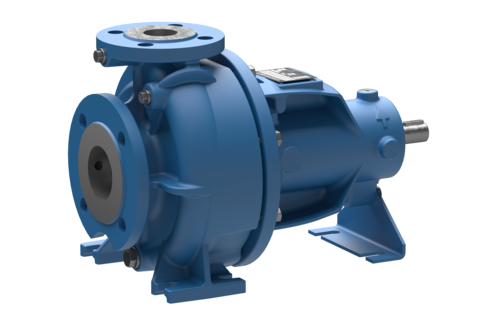

Leak-free, magnetic drive centrifugal pumps. As hermetically sealed centrifugal pumps without shaft feedthroughs, they can be used wherever the explosion hazard, toxicity or odor of the pumped liquid makes it necessary.

350

Max. Delivery Head [m] :145

Max. Outlet Pressure [bar] :25

Max. Fluid Temperature [°C] :350

For a wide range of general industrial and marine applications. Their reliable performance, rugged design, efficiency and versatility keep your industrial and marine processes running smoothly and efficiently.

2.300

Max. Delivery Head [m] :145

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :140

Multistage, high-pressure centrifugal pumps, designed for the efficient transfer of clean and slightly contaminated, non-abrasive fluids.

120

Max. Delivery Head [m] :250

Max. Outlet Pressure [bar] :31

Max. Fluid Temperature [°C] :140

Three-screw pump series for lubricating oil applications. For lubricating oil applications according to API 676, optionally with mechanical sealing according to API 682 and pressures up to 20 bar.

880

Max. Outlet Pressure [bar] :20

Max. Fluid Temperature [°C] :100

Viscosity Range [mm²/s] :5-750