Power Generation Solutions

Providing engineering expertise and products that improve power plant efficiency and performance.

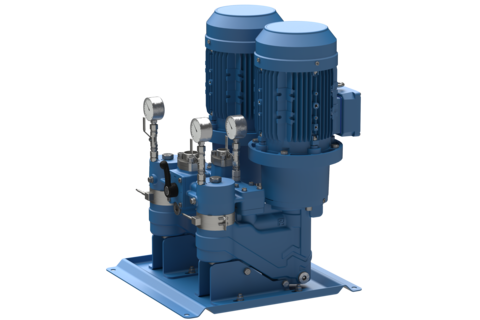

AS THE CONSUMPTION OF ENERGY SOARS worldwide, operators of power plants and production facilities are challenged like never before - not just to meet the growing demand but to deal with an increasingly tough business environment. CIRCOR understands those pressures. We deliver a portfolio of pumps and systems designed for a wide range of flow rates, pressures and fluids. Power generation fluid-handling solutions are engineered for reliable performance under the most rigorous conditions and for extended periods of time. They’re also backed by application experts and technical support for maximum availability and uptime. Because failure is not an option in power generation.

Power Generation Solutions

What Matters Most to You

Pumps and systems from trusted CIRCOR pump brands - ALLWEILER®, HOUTTUIN™ IMO®, and WARREN® - support a wide range of mission critical applications in all types of power plants: hydro, nuclear and fossil. Through our standard and custom engineered solutions, we offer a wide range of designs for fluid handling systems in power generation applications. Power generation operators and engineers turn to CIRCOR to help redefine the metrics that matter most to them:

- Technology: providing the right pump, valve & system solution for every application

- Reliability: maintaining performance of the system regardless of operating conditions

- Availability: maximizing the time for power production

- Uptime: ensuring run-time consistency without fail

- Compliance: sustaining the commitment to environmental responsibility

- Cost-effectiveness: keeping the plant competitive in a tough global economy

CIRCOR Advantage: Providing engineering expertise and products that improve power plant efficiency and performance.

MFG in Monroe, NC & Columbia, KY USA

The 3D series pumps is a general purpose design suitable for many applications including lubrication, fuel transport and burner service, low pressure hydraulic applications and hydraulic elevator service.

500

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :3,250

Max. Fluid Temperature [°F] :250

MFG in Columbia, KY USA

CIG (Crescent Internal Gear) pumps are produced primarily for fluid power applications and aircraft fuel test stands.

115

Max. Fluid Viscosity [cSt min] :5

Max. Fluid Temperature [°F] :180

Max. Diff. Pressure [PSIG] :5000

MFG in Columbia, KY USA

These three screw pumps are used for fuel oil transfer and burner services, machinery lubrication and other industrial pumping applications.

150

Max. Flow Rate [GPM] :100

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :250

Designed specifically for the efficient transfer of fuel oil, lubricating oil, and hydraulic oil. Their versatility makes them the optimal choice for demanding applications, such as pumping low-sulfur marine fuels or marine diesel (MGO).

112

Max. Inlet Pressure [bar] :25

Max. Outlet Pressure [bar] :40

Max. Fluid Temperature [°C] :150

Viscosity Range [mm²/s] :1-3.000