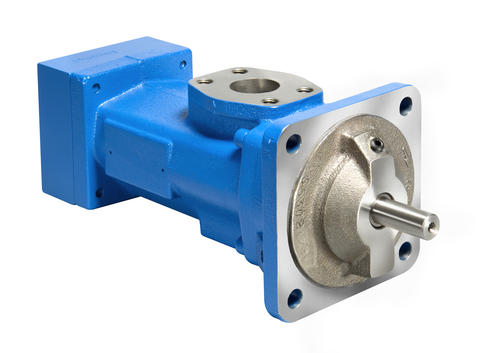

IMO 3G Series

INDUSTRY LEADING PRODUCTS, SERVICES AND SOLUTIONS

MFG in Columbia, KY USA

The 3G series pump is intended for use in lubrication, hydraulic and control oil services. Series 3G pumps are provided for differential pressures to 250 PSIG (17.2 Bar) and flow rates to 55 GPM (208 L/M). Mountings include foot or flange. Casing materials are either cast iron or steel. These three screw pumps are used for distillate fuel oil transfer and burner services, machinery lubrication and other industrial pumping applications. Most sizes are available with a tamper resistant built-in pressure relief valve for protection of the pump from momentary pressure overloads.

Three-Screw Pumps

The Superior Pumping Technology

Discover our three-screw pumps - the clear choice for superior performance and versatility. The unique design with three interlocking spindles provides an extremely efficient and smooth flow, resulting in impressive overall efficiency.

In addition to excellent controllability, the self-priming pumps offer minimal pulsation and remarkably quiet operation, even at high discharge pressures.

Our three-screw pumps are true all-rounders, capable of handling a wide range of fluids of varying viscosities - from low-viscosity fluids to highly viscous substances. It’s robust design and the high wear resistance of the spindles ensure reliability and long life, making them the ideal choice for critical applications in a variety of industries.

- Designed to decrease maintenance and increase intervals between service

- Reduces energy costs

- Available in 17 displacements fitted into five casting sizes

- Intended for use rotating machinery or other equipment needing forced lubrication, circulation or fluid transfer

- Flange or foot mounting available for all sizes

Series 3G pumps are provided for differential pressures to 250 PSIG (17.2 Bar) and flow rates to 55 GPM (208 L/M). Mountings include foot or flange. Casing materials are either cast iron or steel. These three screw pumps are used for distillate fuel oil transfer and burner services, machinery lubrication and other industrial pumping applications. Most sizes are available with a tamper resistant built-in pressure relief valve for protection of the pump from momentary pressure overloads.

This 3G Series available in

Nominal flow rate, GPM/LPM, at 200 PSI (14 BAR), 100 SSU (20 CST)

SPEED RPM

|

3G Series |

3500 |

2900 |

1750 |

1450 |

|

095-1.2D |

5/18 | 4/14 | - | - |

|

095-1.6D |

6/25 | 5/18 | - | - |

|

095-2.0D |

9/33 | 7/26 | 3/11 | - |

|

118-1.6D |

14/52 | 11/40 | 5/17 | - |

|

118-2.0D |

18/69 | 14/54 | 7/26 | 5/19 |

|

143-1.5D |

25/94 | 20/75 | 10/37 | 7/27 |

|

143-1.7D |

28/105 | 22/82 | 11/40 | 8/29 |

|

143-2.0D |

34/128 | 27/101 | 14/52 | 10/39 |

|

162-1.6D |

38/144 | 30/114 | 15/56 | 11/42 |

|

162-2.0D |

50/188 | 40/151 | 21/78 | 16/60 |

Connections-

| Case Material | ||

|

Inlets |

Iron | Steel |

| Axial, straight thread | Standard | N/A |

| Axial, SAE pad | Optional | Standard |

| Radial, straight thread | Optional | N/A |

| Radial, SAE pad | Optional | Optional |

|

Outlets |

||

| Radial, straight thread | Standard | N/A |

| Radial, SAE pad | Optional | Standard |

Straight thread for use with o-ring fittings. SAE pad is for use with mating SAE 4-bolt 3,000 PSI flanges. N/A is not available.

Construction features

Iron or steel case, Dry installation, Horizontal or vertical installation, Self priming, Mechanical shaft seal or sealless

Other data

Design standard: Manufacturer STD

Fluids: Fuel Oils, Lubrication Oils

Sealing: None, Single Mechanical seal

Capacity up to: 200 gpm

Pressure up to: 250 psiD

Viscosity range: 32 to 3,500 ssu

Speed up to: 3,600 rpm

Max. gpm: 200.00

Max. lpm: 757.08

Max. m³/hr: 45.42

Max. bar (dp): 17.24

Max. psi (dp): 250.00

Max. cSt [mm²/s]: 3,238.50

Max. SSU: 15,000.00

Min. cSt [mm²/s]: 1.80

Min. SSU: 32.00

Max. °C: 107.00

Max. °F: 225.00

Min. °C: -18.00

Min. °F: 0.00