Commercial Marine

Future Fuels

Future fuels like methanol, ammonia, and biofuels are key to reducing emissions

Future fuels such as methanol, ammonia and biofuels are increasingly being researched and used in commercial shipping to reduce greenhouse gas emissions, improve air quality and meet stricter environmental regulations. However, switching to these new fuels is a major challenge.

Existing ships need to be retrofitted, and new builds must be designed to accommodate these fuels. Additionally, the entire supply chain needs to be adapted to enable the storage, transportation, and use of these alternative energy sources.

Methanol

Methanol is becoming increasingly important as an alternative fuel in the commercial marine industry. The versatile fuel can be used in dual-fuel engines that allow switching between methanol and conventional marine fuels. This flexibility offers ship operators a reliable solution to meet stringent environmental regulations without compromising operations. Existing ships can also be converted to use methanol through retrofit options, enabling a gradual and cost-efficient introduction of this fuel. In new shipbuilding, methanol offers the possibility of optimally designing engines and storage systems for efficient and safe operation right from the start.

Benefits of methanol:

Methanol burns with significantly lower emissions of sulphur oxides (SOx), nitrogen oxides (NOx) and particulate matter compared to conventional marine fuels.

Methanol can be produced from renewable sources such as biomass, which reduces its overall carbon footprint.

Methanol is liquid at ambient temperature and pressure, which makes it easier to store and handle than gases such as LNG and hydrogen.

Methanol vs. Conventional Marine Diesel

| Feature | Methanol | Conventional Marine Diesel |

|---|---|---|

| State at Room Temp | Liquid | Liquid |

| Energy Density (MJ/kg) | ~19.9 | ~43 |

| Sulfur Content | Very low | Variable, typically higher |

| Combustion Emissions | Lower CO₂, NOₓ, and particulate matter | Higher CO₂, NOₓ, and particulate matter |

| Toxicity | Toxic if ingested | Less toxic than methanol if ingested |

| Flash Point | 11°C | ~60°C |

| Renewability | Can be produced from renewable sources | Primarily fossil-based |

| Corrosiveness | More corrosive, requires special handling | Less corrosive, standard materials |

| Safety Concerns | Highly flammable, toxic vapors | Less flammable, generally safer handling |

Ammonia

Ammonia is a promising future fuel that has the potential to change shipping in the long term. In modified or specially developed combustion engines, ammonia can be used efficiently to power ships. In addition, ammonia can be used in Solid Oxide Fuel Cells (SOFCs) to generate electricity for both propulsion and on-board energy. Converting new and existing ships to ammonia is an attractive option to drastically reduce CO2 emissions.

Benefits of Ammonia:

Ammonia burns CO2-free, especially if it is obtained from renewable sources.

Ammonia has a high energy density, which makes it interesting for long-distance shipping.

Ammonia is already produced and transported in large quantities for industrial purposes, which provides an existing basis for maritime applications.

Ammonia vs. Conventional Marine Diesel

| Feature | Ammonia | Conventional Marine Diesel |

|---|---|---|

| Chemical Formula | NH₃ | C₁₂H₂₄ to C₁₆H₃₄ (varies) |

| State at Room Temp | Gas (liquid under pressure) | Liquid |

| Energy Density (MJ/kg) | ~18.5 | ~43 |

| Sulfur Content | None | Variable, typically higher |

| Combustion Emissions | No CO₂, lower NOₓ with SCR* | Higher CO₂, NOₓ, and particulate matter |

| Toxicity | Highly toxic and corrosive | Less toxic than ammonia if ingested |

| Flash Point | Not flammable under normal conditions | ~60°C |

| Renewability | Can be produced from renewable sources | Primarily fossil-based |

| Corrosiveness | Highly corrosive, requires special materials | Less corrosive, standard materials |

| Safety Concerns |

Toxic, corrosive, and pressurized |

Less flammable, generally safer handling |

Biofuels

Biofuels are a flexible and sustainable alternative to conventional fossil fuels. They can be used in existing engines and equipment, often without major modifications, making them an attractive option for shipping. Biofuels are produced from renewable sources such as vegetable oils, algae and waste and offer an environmentally friendly way to meet energy needs while reducing CO2 emissions. The use of biofuels enables ship operators to comply with environmental regulations and make a positive contribution to climate protection.

Benefits of Biofuels:

Use of waste products and rapidly renewable raw materials, thereby reducing dependence on fossil fuels.

Often compatible with existing technologies and infrastructures, which makes the changeover easier.

Reduction of pollutants such as sulphur oxides (SOx) and particulate matter, which contributes to better air quality and reduces environmental pollution.

The use of future fuels in marine applications requires a carefully selected pump system to support the entire process from storage to combustion. With our deep understanding and experience, we support with the right pump selection.

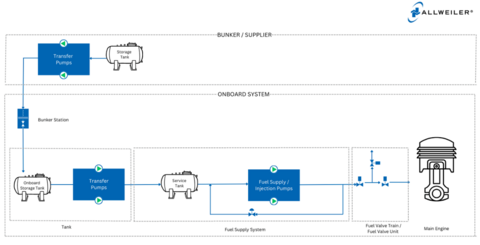

Figure 1: Pumps for Future Fuels in Commercial Marine Vessels

Transfer Pumps

Transfer pumps move the fuel between different tanks on board, for instance main tank to service tank.

The requirements for transfer pumps are:

Leakage-free to protect the environment.

Robust design for durable and trouble-free operation.

Materials that can withstand the chemical properties of methanol, ammonia and biofuels.

Fuel Supply Pumps

Fuel suppy pumps ensure a stable pressure supply to the engine to ensure optimum engine performance and optimized emissions control.

The requirements for fuel supply pumps are:

Ability to control flow over a wide range while maintaining constant pressure.

The efficiency of the system depends on the efficiency of the pump itself, as well as the energy wasted in bypass lines in case the overflow has to be circled back to the tank.

Reliable performance under extreme operating conditions.

Space is rare onboard of ships. Pumps are preferably mounted vertically to save space.

Chemical-resistant stainless steel materials, hermetically sealed magnetic drives and explosion-proof design for safe operation.

Our Solutions

ALLWEILER offers a comprehensive range of pump solutions specifically designed for use with future fuels. Our centrifugal and three-screw pumps are designed for maximum efficiency, reliability and safety to meet the requirements of the marine industry. We support you every step of the way.

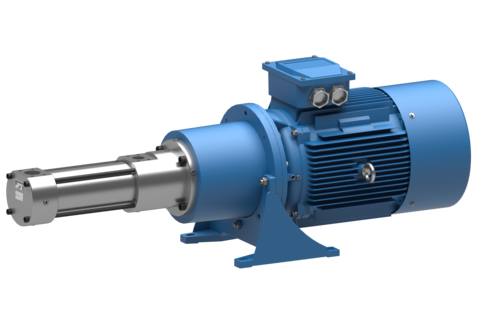

Three-Screw Pumps for Future Fuels

Our latest generation of three-screw pump technology is already fully compatible with future fuels such as methanol, ammonia and biofuels.

These pumps offer maximum reliability for the injection of fuels in the medium and high pressure range. With its chemical resistant components and integrated safety functions, they are an optimal solution for use with methanol, ammonia and biofuels – naturally complaint with the class rules and regulations.

ALLMAG® Series

Allweiler ALLMAG® pumps offer safe and leak-free pumping of future fuels such as methanol and ammonia. Their magnetic coupling and hermetically sealed system make them ideal for handling flammable, toxic or corrosive liquids. Without a conventional shaft seal, they minimize the risk of leaks and emissions - perfect for demanding marine applications.