Industrial Solutions

Offering comprehensive solutions that keep manufacturing processes online and facilities operating reliably and safely.

INDUSTRY MAKES THE WORLD WORK. CIRCOR keeps your manufacturing processes online and operating at peak efficiency. We understand the rotating equipment requirements of machine builders. That’s why we design, engineer, and manufacture rugged fluid-handling solutions for a vast range of critical industrial applications with complex requirements, helping to ensure uninterrupted, precision performance.

Industrial Solutions

What Matters Most to You

You demand optimum performance of your critical equipment. CIRCOR delivers the right solutions across a wide range of industries, including chemical processing, mining, pulp and paper, waste water and building construction. In these global markets, engineers and operators rely on pumps, engineered systems, critical application expertise and technical support from trusted CIRCOR brands – Allweiler®, Imo®, Houttuin™, Tushaco®, Warren® and Zenith® – for fluid-handling solutions that deliver on local requirements, such as:

- Increased output in a pulp and paper bleach plant by as much as one-third, without increasing baseline costs.

- Reduced the footprint by 30% in a chemical process plant.

- Extended the life of a PC pump stator three times longer in the worst sludge applications.

Engineers and operators of industrial plants face greater challenges than ever before in terms of environmental protection‚ operations‚ safety and availability. CIRCOR can help you overcome these challenges by working with you from the beginning of the design process‚ all the way through to startup and operation. Our expertise can help you solve your toughest challenges in these sub-markets:

- Chemical

- Pulp and Paper

- Environmental Engineering

- Mining and Mineral Processing

- Steel & Primary Metals

- Machine Construction

- Gear Boxes and Compressors

- Electric Vehicles

- Tool Machines

- Construction & Building

- Heating and Cooling

- Food & Beverages

- Industrial Boilers

CIRCOR Advantage: Offering comprehensive solutions that keep manufacturing processes online and facilities operating reliably and safely.

MFG in Monroe, NC & Columbia, KY USA

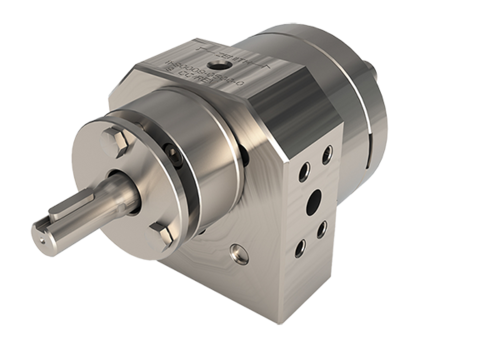

The 3D series pumps is a general purpose design suitable for many applications including lubrication, fuel transport and burner service, low pressure hydraulic applications and hydraulic elevator service.

500

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :3,250

Max. Fluid Temperature [°F] :250

MFG in Columbia, KY USA

This series pump are dependable solutions for: Power units of hydraulic lifts, e.g. passengers, panoramic, hospital, handicapped people, goods, small-loads and automobile lifts; Lifting platforms and theatre stages; Other hydraulically driven machines.

240

Max. Pressure [psiD] :1,000

Max. Viscosity [SSU] :3,500

Max. Speed [rpm] :3,600

MFG in Monroe NC USA

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500