A Continuity of Excellence

A legacy of energy-efficient performance lives on.

At Houttuin, our original innovation was a pump that could handle large quantities of viscous liquids while minimizing energy loss. Efficiency caught on.

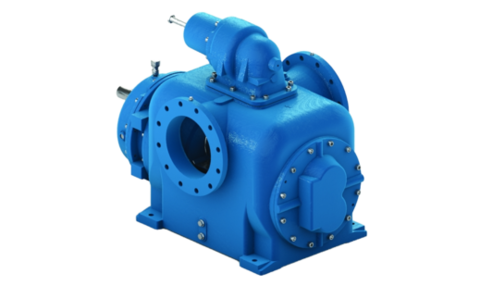

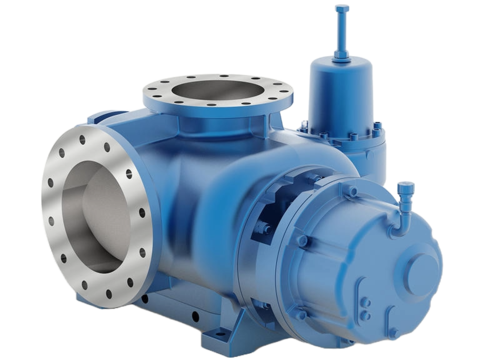

Houttuin‚ a CIRCOR brand‚ developed the original pump design that became the blueprint for today's low-pressure‚ twin-screw positive displacement rotary pumps. These pumps, initially built in 1929 for the Dutch coal industry, solidified our reputation for manufacturing high-quality, energy-efficient and cost-effective industrial pumps.

Houttuin Pumps are used worldwide in a variety of industries, including chemical and petrochemical‚ tank farms‚ power plants‚ offshore‚ refining‚ shipbuilding and marine‚ soap‚ food‚ beverage‚ plastics and sugar.

To manufacture its complex screw shafts to the extremely high tolerances necessary for its pumps, Houttuin employs specially designed and built CNC machines. Equally important, every pump undergoes both a hydrostatic test and running test at our testing facility to approximate—as nearly as possible—actual duty conditions.

Houttuin is ISO 9001-certified and has manufacturing operations in Monroe, North Carolina and Allweiler India, Daman.

For pumping clean, lubricating fluids and lube oil applications. The HTN LO pumps provide compact, reliable solutions for high flow requirements in transport and lubrication applications.

1.000

Max. Diff. Pressure [bar] :16

Max. Fluid Temperature [°C] :80

Viscosity Range [cSt] :10-760

Suitable for the requirements of the chemical and refinery industries. Thanks to the modular design of the pumps, they can be optimally adapted to the specific and demanding requirements.

2.500

Max. Diff. Pressure [bar] :40

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

Optimized for dry running, stripping and self-priming to ensure low NPSH requirements. In addition, low, medium and high pressure versions are available and the pumps are available for CIP.

5.000

Max. Diff. Pressure [bar] :60

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

Because they're designed to move fluid at a consistent rate, regardless of pressure, twin-screw pumps deliver results where centrifugal pumps are unable to and are able to actually increase efficiency as viscosity rises.

But twin-screw pumps don't just offer performance, since they are designed to eliminate metal-on-metal contact which means a longer life, improved reliability and less downtime.

In addition, unlike other pump options, twin-screw pumps can:

- Tolerate contamination

- Handle a large range of viscosities and fluids

- Low NPSH required

- Run dry

- Low fluid sheer

- Operate at variable speeds

And with twin-screw pumps' ability to handle multiple liquids at multiple viscosity rates, they can be used for a wide range of applications.

AFTERMARKET

Your best resource for service, maintenance and quality parts.

No one knows your valves, pumps and systems like the experts at CIRCOR. Our certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry. We have the resources to troubleshoot, analyze and solve even your most complex issues in ways other service options are unable to.

ARTICLE

Twin-Screw Pumps in Tank Terminals

In this article published by Tank Storage Magazine, Axel Jäschke, business development director at CIRCOR explains how twin-screw pumps can improve flexibility, simplicity and efficiency at tank terminals.

CASE STUDY

Keeping the Lights On: Performance Insurance for Mission Critical Pumps in A Peaking Power Plant

Just because a twin-screw fuel pump is more than 40 years old and has never seen a doctor doesn’t mean it shouldn’t. Read our new case study to find out how a primary supplier of backup electrical power benefited from a comprehensive health check performed by a CIRCOR authorized service center on two mission critical pumps. When they learned the pumps were operating well outside the factory clearances and design tolerances the equipment was built for, there were decisions to make.

HOUTTUIN 249.TT

Smaller. Faster. More Reliable.

The Houttuin 249.TT two-screw pump series delivers improved flow in a much more streamlined package

ENGINEERED TO MEET DEMANDS AND EXCEED EXPECTATIONS

When creating the Houttuin 249.TT series, we kept our end users top-of-mind and created a better performing, smaller sized two-screw pump to meet their needs. In addition to an incredible flow rate, the Houttuin 249.TT series has fewer parts, is lighter in weight and offers a lower net positive suction head (NPSH) than similar sized pumps.

THE NEED FOR SPEED

In transfer and unloading applications, the longer the process takes, the more it costs. With the Houttuin 249.TT series, you'll be able to unload fluids faster than ever. And your performance won't vary even if storage fluid levels or inlet pressures do.

SMART TECHNOLOGY

Twin-Screw Pump Smart Technology Package Safe and Reliable Tank Unloading & Stripping

SIMPLY INSTALL IT, SET IT AND FORGET IT.

CIRCOR’s Twin-Screw Smart Technology Package automatically adjusts flow in real time to operating conditions protecting the pump from cavitating, while maintaining the highest capacity possible. Our patented algorithm, designed to detect cavitation, makes it possible to preserve required flow in normal operation without oversizing the pump for worst-case scenarios that may occur when stripping a tank or pipeline.

Contact

We are here for you! Contact our team of experts for advice, technical information or customised solutions.

Contact Form

If you have any questions, praise, constructive criticism, or suggestions for improving our products or services, please do not hesitate to contact us.

Sales Partner

Our worldwide network of sales partners ensures that you always have the right contact in your region.