Herringbone Gear Pump Technology

Engineered for Smooth, Reliable Flow.

Delivering precise, quiet, and continuous flow, IMO Herringbone Gear Pumps are engineered to meet the toughest fluid-handling challenges with efficiency and durability.

Definition

What is Herringbone Gear Pump?

A herringbone gear pump is a positive displacement pump that uses two intermeshing gears with double helical V-shaped or herringbone, teeth to move fluid. The design features two sets of helical teeth inclined in opposite directions, forming a “V” pattern similar to a herringbone fish skeleton, hence the name.

A herringbone gear pump is a high-performance, positive displacement pump that delivers steady flow with minimal noise and axial load, thanks to its double-helical gear design.

IMO herringbone gear pumps deliver smooth, pulse-free flow, reduced vibration, and quiet operation, all while lowering total cost of ownership. With inherently balanced, double-helical gears and outstanding hydraulic stability, these pumps are ideal for even the most challenging industrial fluids and environments.

Technology

How Herringbone Gear Pumps Work?

A Herringbone Gear Pump is a positive displacement pump that moves fluid by the rotation of double helical V-shaped gears. The process works as follows:

- Fluid enters the pump: As the gears rotate, the teeth unmesh on the suction side, creating a vacuum that draws fluid into the spaces between the gear teeth and the pump casing.

- Fluid is carried around the gears: The fluid is trapped in the cavities formed by the gear teeth and the casing, moving around the outer perimeter from the suction side to the discharge side.

- Fluid is discharged: On the discharge side, the teeth mesh together, forcing the fluid out of the pump under pressure.

Superior Engineering and Low Cost of Ownership

Designed to reliably handle viscous fluids across a broad range of flows and pressures, IMO Herringbone gear pumps feature double helical, herringbone type gears. These pumps are widely used because of their reliabilty and low cost of ownership. Available in a variety of materials and mounting configurations, these robust pumps provide high-efficiency, pulse-free pumping, even under the most challenging conditions

Application:

- Lubeoil/hydraulic oil circulation

- Process industries

- OEM

- Filtration equipment

- Fire foam systems

- Petrochemical blending and transfer

- Food and beverage industry

Benefits

THAT GO STRAIGHT TO YOUR BOTTOM LINE

For Accuracy, Quiet Operation and Superior Flow Control here are some of the key advantages of IMO Herringbone Gear Pumps

Continuous, pulse-free operation ensures precise fluid transfer.

Balanced axial forces minimize wear on bearings and shafts.

Optimized gear design improves volumetric efficiency and reduces energy consumption.

Suitable for industrial, marine, chemical, and hydraulic systems.

Handles heavy-duty operation in harsh environments with consistent performance.

Low vibration and noise levels improve operational comfort and reliability.

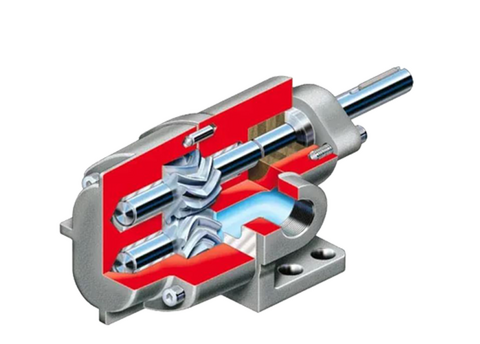

IMO GA Series gear pumps have long been workhorses in highly viscous applications within a multitude of industries due to their dependability, efficiency and low total life cycle costs. Engineered to reliably pump viscous fluids over a broad range of flows and pressures.

27 m3/h (120 gpm)

Pressures to :17 bar (250 psi)

Temperatures to :175°C (350°F)

Speeds to :1800 rpm

Viscosities to :50 000 ssu

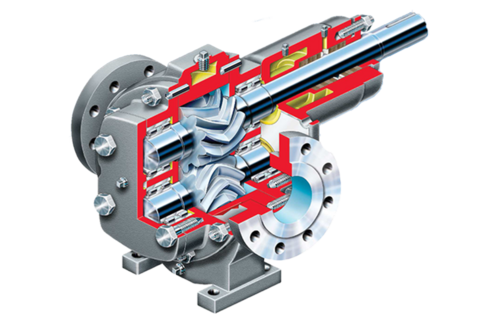

GR Series pumps provide high efficiency, pulse-tree pumping, even under the most challenging conditions. They are designed to handle viscous fluids

across a broad spectrum of flows and pressures. The GR Series' simple external design has only two moving parts and only one shaft seal to ensure long life and ease of maintenance.

275 m3/h (1200 gpm)

Pressures to :35 bar (500 psi)

Temperatures to :350°G (650°F)

Speeds to :1800 rpm

Viscosities to :33 000 cps (1 million ssu)

Standard sizes from :40 to 200 mm (1.5 to 8 in)

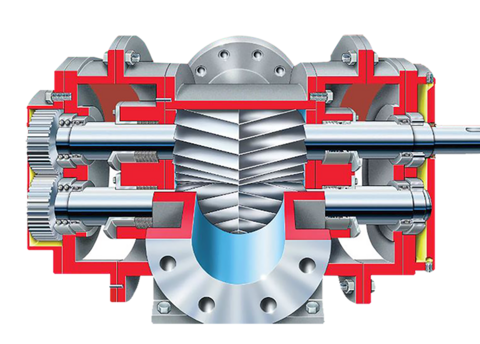

Extremely rugged and unusually compact for its high capacity and range, the Gearex rotary pumps are generally compliant with AP/ 676, second edition. Precision machined herringbone pumping gears provide low vibration, pulseless discharge while timing gears quietly and evenly transfer power to the driven rotors, ensuring minimal wear and long life

180 m3/h (800 gpm)

Pressures to :20 bar (300 psi)

Temperatures to :-50°C (-60°F) to 450°C (850°F)

Speeds to :1800 rpm

Viscosities to :32 to 1 million ssu

Support

How to choose the right IMO Herringbone Gear Pumps

Due to the process-optimized variety of models, selecting the right Herringbone gear pump requires experience.

Several factors are important:

Fluid properties, operating conditions, environmental conditions, the overall system and applicable standards and regulations.

Finding the right, cost-effective Herringbone gear pump that matches to the process requirements best can be a challenge.

Our team of experts helps to make the right choice.

We will work with you to review your application and determine which pump meets your needs best.

Trusted Brand

Smooth, silent performance

With millions of pumps currently in service around the world, Imo’s reputation for quiet, continuous reliability has a lot of momentum behind it.

CIRCOR Pumps North America LLC is a leading marketer and world-class manufacturer of Imo Pump products with competitive advantages. By developing supplier‚ distributor and customer networks for various industries and market segments‚ we achieve global reach.

Manufacturing rotary positive-displacement three-screw, herringbone gear pumps and gear pumps, the Imo Pump brand meets the strict requirements of our customers' applications and can offer precise‚ and reliable performance. Our experienced engineering staff can help you solve any design‚ engineering or process issue.