Zenith Pumps for Filter Production

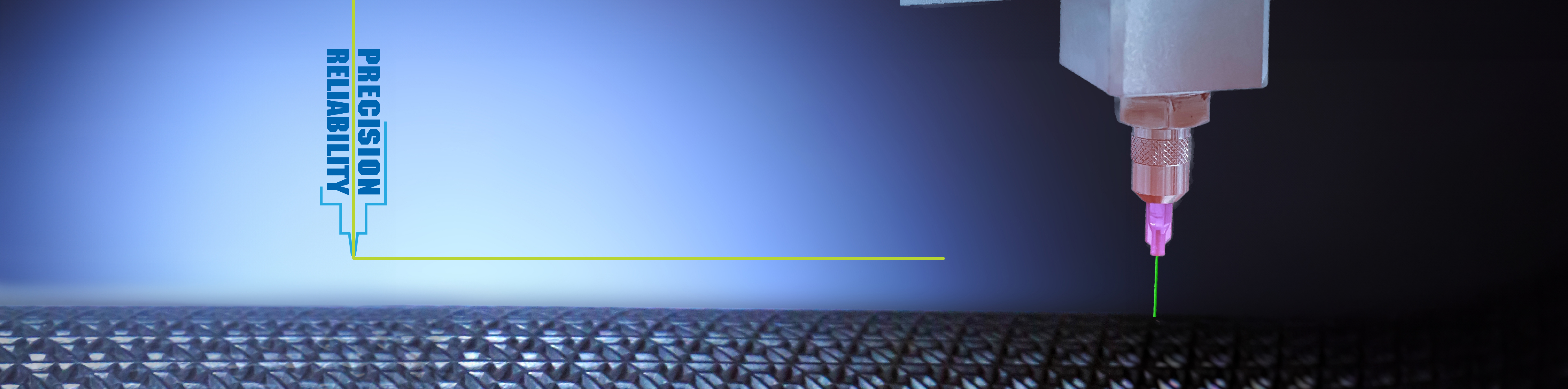

Elevate efficiency and precision in filter production

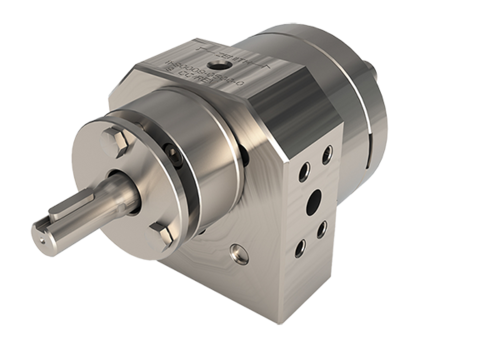

Maximize Your Savings with Zenith’s Precision Metering Pumps. With its robust design and ability to handle abrasive fluids, additives, adhesives, sealants, polyurethane and multi-component blending, these pumps are built to deliver outstanding performance. No one has more experience or material options for dispensing sealants and adhesives than Zenith. Contact us to determine what pump series is best for you.

Adhesives and Sealants Applications for Filter Manufacturing

Glueing Pleats

Metal Caps Glueing

PU Injection

Filter Glueing Inside & Out

Hollow Fiber

+ Many More Applications

Why Zenith Metering Pumps?

Seal-less

Accuracy

High Viscosity

High Temperature

Best Sales Partner

Made in USA

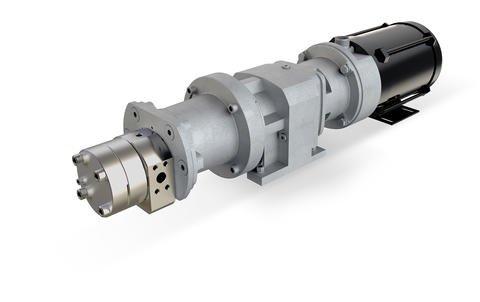

Your first choice for 2K, 3K and more... Adhesives and Sealants dispensing/dosing pump systems from Zenith.

Upgrade Your Filtration Process with Zenith Precision Gear Pumps

Efficient Metering Solutions for Filter Production and Beyond

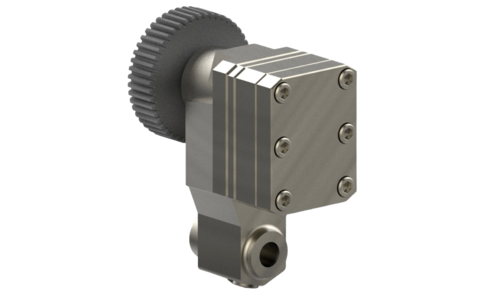

Experience seamless filtration production with Zenith Precision Gear Pumps and cutting-edge metering systems. Whether it's adhesives, sealants, potting compounds, or sealing foams, our technology ensures precise metering, mixing, and application for impeccable results.

In the realm of filter manufacturing, our solutions play a pivotal role. From bonding filter mats to housing with adhesives or PU potting to applying sealing foams for airtight seals, Zenith systems excel in every aspect of the process.

Our diverse range of systems, including Series B, Series 9000, Series 9000MD, Spin Finish, and H Series, caters to all filtration applications. Each system is meticulously tailored to meet your specific requirements, guaranteeing reliability and precision at every step.

Take your filter production to new heights with Zenith Precision Gear Pumps. Unlock unparalleled efficiency, accuracy, and performance for gasketing, bonding, and potting applications.

| Polyurethanes | Polyurethane, Foams, Epoxies, Undercoating, Silicones, Emulsions, Elastomers |

|

Flexibility in handling various isocyanates & polyols |

| Adhesives & Sealants | Hot Melts, Caulking, Laminates, Casketing, UV - PSA, Coating, Extrusions, Spray |

Flexibility in handling various isocyanates & polyols |