Product Search

Real-world sizing and selection tool for a variety of the most popular pumps across the CIRCOR portfolio.

Search

Optimizes all hydraulic characteristics such as flow pattern, power absorption and distribution, and lubrication to ensure long service life and maximum efficiency.

3.800

Max. Discharge Pressure [bar] :6

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :300.000

MFG in Monroe, NC USA

For polymer extrusion applications where product uniformity is critical. BB PEP Series pumps are specifically designed for medical tubing applications where high precision and ease of disassembly and cleaning are desired.

750

Max. Flow Rate [lbs/hr] :7,000

Max. Fluid Temperature [°F] :950

Max. Disch. Pressure. [PSI] :10,000

Materials :Through hardened tool steel, Corrosion resistant nickel and cobalt alloys (Stellite)

Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR). Suitable for a wide range of fluids.

1.600

Max. Discharge Pressure [bar] :10

Max. Fluid Temperature [°C] :100

Max. Viscosity [mm²/s] :190.000

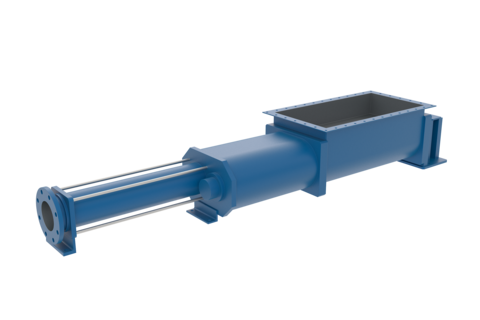

For handling viscous, abrasive or solids-laden materials in various industrial applications. Their unique hopper design enables efficient and smooth product transfer in this tough environment.

1.700

Max. Differential Pressure [bar] :36

Max. Fluid Temperature [°C] :135

Max. Solid Content [%] :45

Max. Viscosity [mm²/s] :1.000.000

Powerful, but also extremely versatile pump series. Whether thinor highly viscous liquids, neutral or aggressive media, gaseous or foaming liquids – our pumps effortlessly master every challenge.

12.000

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :250.000

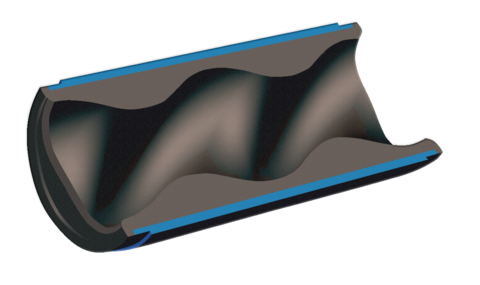

Specifically developed for our progressing cavity pumps with a clear focus on cost effectiveness. The compound formulation is the key to how long a stator will maintain its original flow rate.

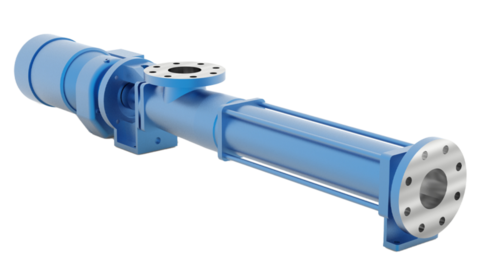

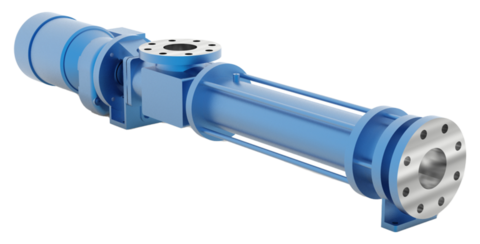

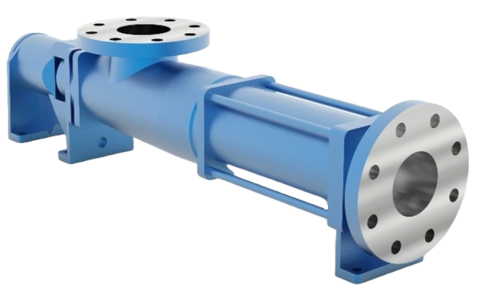

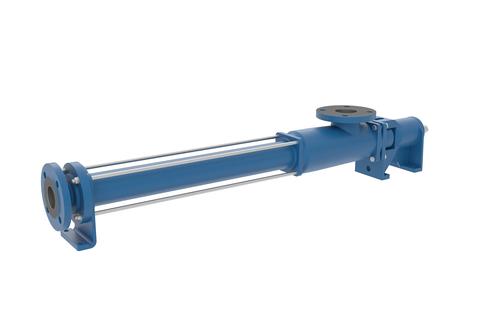

The modular design allows for high production efficiency and flexibility in meeting specific customer requirements. The series covers a wide pressure range up to 48 bar, with special versions for the oil and gas industry exceeding this limit.

7.500

Max. Differential Pressure [bar] :48

Max. Fluid Temperature [°C] :150

Max. Solid Content [%] :60

Max. Viscosity [mPas] :300.000

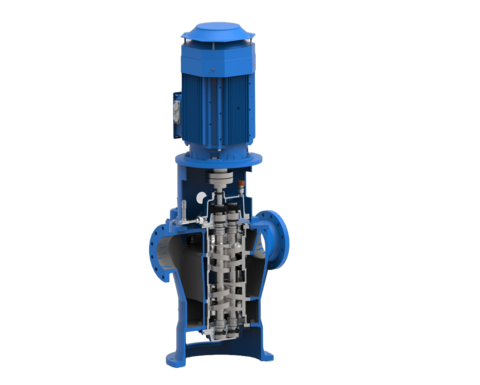

Vertical progressing cavity pumps are the ideal solution for emptying tanks, pits, basins or containers. Thanks to their vertical design, they are submerged directly in the liquid to be pumped and ensure safe, efficient and trouble-free pumping.

2.000

Max. Differential Pressure [bar] :48

Max. Fluid Temperature [°C] :150

Max. Solid Content [%] :60

Max. Viscosity [mPa s] :300.000

For pumping large volumes of liquid at low heads. These pumps are extremely versatile and offer superior solutions for handling a wide range of fluids, from highly corrosive to slurries.

50.000

Max. Delivery Head [m] :12

Max. Discharge Pressure [bar] :6

Max. Fluid Temperature [°C] :200

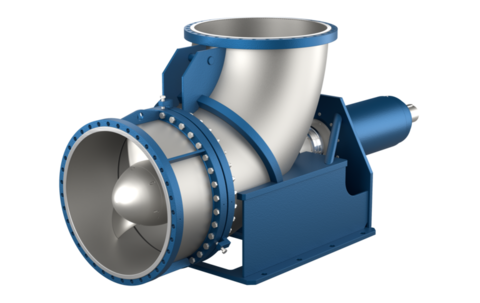

Anti-Heeling-Systems keep ships in balance during loading and unloading. Innovative inline propeller pump, also known as axial flow pump, designed specifically for use in Anti-Heeling-Systems.

1.400

Max. Delivery Head [m] :20

Max. Differential Pressure [bar] :2,5

Max. Fluid Temperature [°C] :40

No. of Stages :1 & 2

Instead of wasting unused energy as heat, the ERCV uses an innovative combination of a volumetric screw-machine and advanced actuator technology to recover unused hydraulic energy.

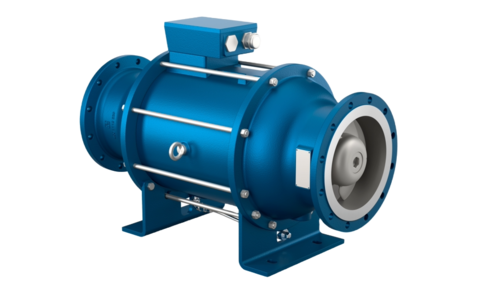

Non-contact, friction-based screw heating pumps are extremely versatile and can operate at temperatures up to 400 °C. Our horizontal or vertical heating pumps provide a robust solution for simultaneous heating and pumping of fluids in one compact unit.

2 MW

Max. Differential Pressure [bar] :40

Max. Fluid Temperature [°C] :400

Max. Viscosity [cSt] :10.000