Crescent Internal Gear Pump Technology

A pump with features that you’ve been looking for.

The Imo Crescent Internal Gear (CIG) pump line is a family of rugged, reliable, high pressure pumps with silent, low-ripple performance. Longer life, lower pressure ripple, lower contamination sensitivity and maximum energy savings result in the highest “Total Savings of Ownership” across the entire life-cycle of your pumping equipment solution.

Definition

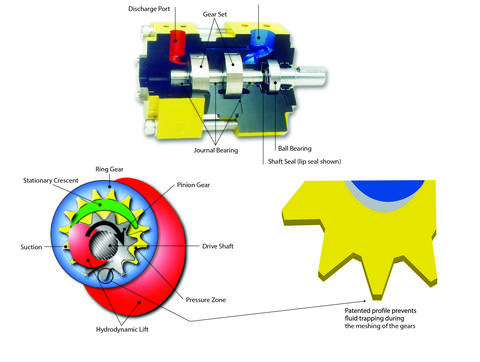

What are Crescent Internal Gear Pumps?

CIG (Crescent Internal Gear) pumps are produced primarily for fluid power applications and aircraft fuel test stands.

They are available in multiple stages for very high pressure or moderate pressure on very low viscosity fuels. Pumps are also available in double pump configurations which share a common inlet port but deliver two independent flows for supporting multiple machine functions.

The patented tooth profile of CIG pumps avoids trapping fluid. The result is a very low pulsation, extremely quiet high efficiency pump.

Single pumps are available in 54 different models and double pumps in over 1300 different combinations.

Single pump flow rates from 1 to 125 GPM ( 4 to 475 L/M) with continuous pressure ratings to 5000 PSIG (345 BAR).

Pumps are available in single and double configurations. The double pumps have a common inlet port and two independent discharge ports. Pumps can be provided in a number of staging arrangements allowing very high pressure capability or high pressure at low viscosity.

Technology

Unique design principles of the CIG pump.

The success of the CIG series pump lies in the fundamental design principle of using hydrodynamic lift to separate all moving contact areas. This internal gear design does not use any axial or radial compensation, virtually eliminating contamination caused by axially loaded side plates or radial thrust shoe designs. The only loaded parts are the sleeve bearings of the drive shaft and the housing surrounding the outer ring gear, which also acts as a sleeve bearing.

Hydrodynamic lift (fluid film support) is created through the friction of the fluid media. This is formed between the shaft bushing and the shaft and also between the ring-gear outside diameter and gear-housing inside diameter. The hydrodynamic lift prevents metal-to-metal contact between the stationary and rotating components. Therefore there is no metal contact or wear. The ring-gear and shaft float on a film of the fluid being pumped.

The patented gear tooth profile compensates for metal-to-metal contact of the gear teeth. This patented gear tooth profile greatly reduces the Hertzian compression stresses (gear tooth contact loads) on the gear flanks compared to an Involute profile. Also, the relative velocities in the area of the largest forces on the gear teeth are minimal in relation to the strength of the material.

CIG pumps are commonly used for lubrication, high-pressure fuel and hydraulic applications in mobile or stationary environments. It is capable of handling a broad range of fluids with low or high viscosities at flow rates from 1 to 115 GPM (3.8 to 435 liters per minute) in a single pump.

Imo Pump

Crescent Internal Gear Pump Features

The CIG pump design combines the best features of a variety of technologies in one single, efficient unit:

- Simple design as in conventional gear pumps

- High pressure capability as in piston pumps

- Low viscosity operational capability as in centrifugal pumps

- Low noise levels and low ripple flow as in screw pumps

What do low operating noise levels mean to you?

- No acoustic enclosures required

- No remote location of the pump

- No lengthy runs of piping

Applications

Perfectly suited to a wide variety of

challenging applications, including:

- Hydraulic power

- Fatigue test equipment

- Marine hydraulics

- Liquid fuel injection

- Fuel component test equipment

Video

How do Crescent Internal Gear (CIG) Pumps work?

The success of the CIG series pump lies in the fundamental design principle of using hydrodynamic lift to separate all moving contact areas. This internal gear design does not use any axial or radial compensation, virtually eliminating contamination caused by axially loaded side plates or radial thrust shoe designs. The only loaded parts are the sleeve bearings of the drive shaft and the housing surrounding the outer ring gear, which also acts as a sleeve bearing.t.

Watch the video to see how crescent Internal Gear Pumps work.

| Mounting Flange: | Ductile Iron (nitride hardening optional) |

| Gear Housing(s): | Ductile Iron (nitride hardening optional) |

| Rear Cover: | Aluminum (steel optional) |

| Seal Housing: | Aluminum (steel optional) |

|

Ring Gear: |

Pearlitic Gray Iron (nitride hardening optional) |

| Pinion Gear: | Alloy Steel (nitride hardened) |

| Shaft: | Alloy Steel (nitride hardened) |

| Pump Barrel: | Steel (multi-stage pumps only) |

| O-rings: | Fluorocarbon |

| Shaft Seals: | Teflon inner / Fluorocarbon outer lip type (mechanical seal optional) |

| Sleeve Bearings: | Metal-Polymer composite |

| Flow Range: | 1 to 115 usgpm |

| Fluid Viscosity: | .5cSt minimum |

| Inlet Pressure: | 7psig (options available to allow 100+psig) |

| Differential Pressure: | To 5000psig |

| Temperature: | 180˚F (options to allow 250˚F+) |

| Speed: | To 4500rpm (dependent on Frame size, inlet pressure and fluid viscosity) |

Real World Benefits

THAT GO STRAIGHT TO YOUR BOTTOM LINE

CIG pump performance is field proven with thousands of operating units installed worldwide. Here's why:

Typically less than 1% peak-to-peak at maximum pressure performance.

Due to the patented gear tooth profile and its low Hertzian compression stresses during the meshing phase of the gears, plus the incorporation of the hydrodynamic principle.

Excellent resistance to flow degradation when compared to most other pump designs. Durable materials, plus design simplicity, provide outstanding durability.

Typically less than 68 db(A) for most applications. The patented gear tooth profile reduces trapped fluid and backlash in the gears reducing pressure pulsations, keeping airborne noise to a minimum.

Able to operate at high speed without a suction boost, while delivering excellent suction lift characteristics.

Space-saving single-, double- or triple-pump configurations where each pump shares a common drive shaft requiring only one driver.

Able to handle fluids with viscosities as low as 0.5 cSt and pressures up to 5000 PSI (345 BAR).

Support

How to choose the right Crescent Internal Gear Pump

Due to the process-optimized variety of models, selecting the right CIG pump requires experience. Several factors are important: Fluid properties, operating conditions, environmental conditions, the overall system and applicable standards and regulations. Finding the right, cost-effective CIG pump that matches to the process requirements best can be a challenge.

Our team of experts helps to make the right choice.

We will work with you to review your application and determine which pump meets your needs best.

Trusted Brand

Crescent Internal Gear Pumps from IMO

CIRCOR Pumps North America LLC is a leading marketer and world-class manufacturer of Imo Pump products with competitive advantages. By developing supplier‚ distributor and customer networks for various industries and market segments‚ we achieve global reach.

Manufacturing rotary positive-displacement three-screw and gear pumps, the Imo Pump brand meets the strict requirements of our customers' applications and can offer precise‚ and reliable performance. Our experienced engineering staff can help you solve any design‚ engineering or process issue.

Industries served include hydrocarbon and chemical processing‚ crude oil transport‚ Navy and commercial marine‚ power generation‚ pulp and paper‚ hydraulic elevator and general machinery.

Manufacturing is accomplished under ISO 9001 Management Systems. We have also received TS 16946 certification‚ the highest automotive quality standard issued.