Product Search

Real-world sizing and selection tool for a variety of the most popular pumps across the CIRCOR portfolio.

Search

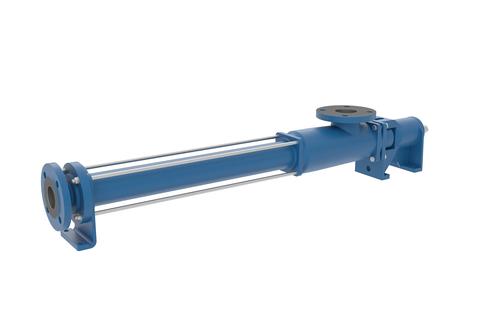

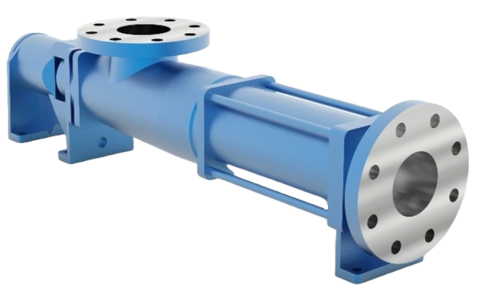

Proven, reliable solution for lubricating hydrodynamic plain bearings in large rotating equipment. This requires lubricating oil pumps that can be relied upon to provide long service life with minimal maintenance.

550

Max. Delivery Head [m] :150

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :100

The modular design allows for high production efficiency and flexibility in meeting specific customer requirements. The series covers a wide pressure range up to 48 bar, with special versions for the oil and gas industry exceeding this limit.

7.500

Max. Differential Pressure [bar] :48

Max. Fluid Temperature [°C] :150

Max. Solid Content [%] :60

Max. Viscosity [mPas] :300.000

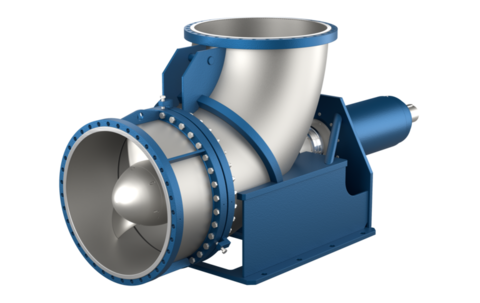

For pumping large volumes of liquid at low heads. These pumps are extremely versatile and offer superior solutions for handling a wide range of fluids, from highly corrosive to slurries.

50.000

Max. Delivery Head [m] :12

Max. Discharge Pressure [bar] :6

Max. Fluid Temperature [°C] :200

Pump difficult media just as reliably as sensitive media in precisely metered quantities, no seals or valves needed. Maintenance and wear of these components are completely eliminated.

60

Max. Achv. Neg. Press. [bar] :-0,95

Max. Fluid Temperature [°C] :80

Max. Viscosity [mm²/s] :100.000

For dosing and handling high-viscosity, solids-laden fluids. We have combined proven and durable features from our proven industrial pump range with optimized rotor and stator geometries to ensure the highest dosing accuracy.

33

Max. Differential Pressure [bar] :24

Max. Fluid Temperature [°C] :100

Max. Viscosity [mPas] :28.000

Stainless steel CIP pumps for demanding media. They feature a high quality stainless steel design for easy cleaning and maintenance.

900

Max. Differential Pressure [bar] :12

Max. Viscosity [mm²/s] :150.000

Max. Fluid Temperature [°C] :130

Max. Stages :2

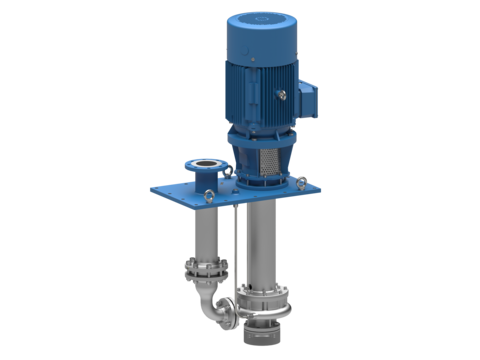

Vertical progressing cavity pumps are the ideal solution for emptying tanks, pits, basins or containers. Thanks to their vertical design, they are submerged directly in the liquid to be pumped and ensure safe, efficient and trouble-free pumping.

2.000

Max. Differential Pressure [bar] :48

Max. Fluid Temperature [°C] :150

Max. Solid Content [%] :60

Max. Viscosity [mPa s] :300.000

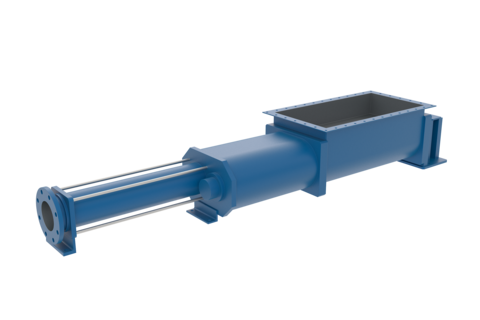

For handling viscous, abrasive or solids-laden materials in various industrial applications. Their unique hopper design enables efficient and smooth product transfer in this tough environment.

1.700

Max. Differential Pressure [bar] :36

Max. Fluid Temperature [°C] :135

Max. Solid Content [%] :45

Max. Viscosity [mm²/s] :1.000.000

Tailor-made for demanding cooling water circulation tasks in large diesel engines. Driven directly by the transmission, they provide efficient and reliable cooling.

550

Max. Delivery Head [m] :150

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :120

Self-priming side channel pumps are used for pumping aggressive and mechanically clean liquids, especially for small flows and high heads.

36

Max. Delivery Head [m] :350

Max. Suction Head [m] :7

Max. Outlet Pressure [bar] :40

Max. Fluid Temperature [°C] :220

The solution when it comes to size reduction of solids. They offer unsurpassed performance and efficiency when processing abrasive media, corrosive liquids and solids.

160

Max. Delivery Head [m] :3,0

Max. Fluid Temperature [°C] :80

Powerful, but also extremely versatile pump series. Whether thinor highly viscous liquids, neutral or aggressive media, gaseous or foaming liquids – our pumps effortlessly master every challenge.

12.000

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :250.000