IMO GA Series Herringbone Gear Pump

Superior Engineering and Low Cost of Ownership

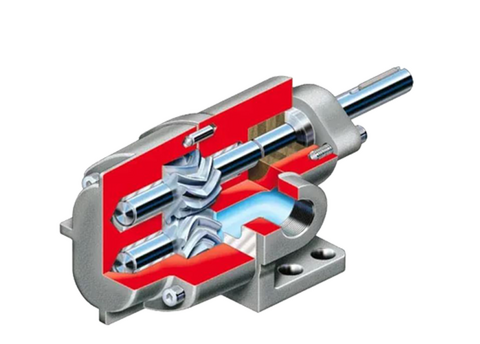

GA Series gear pumps have long been workhorses in highly viscous applications within a multitude of industries due to their dependability, efficiency and low total life cycle costs. Engineered to reliably pump viscous fluids over a broad range of flows and pressures, the GA Series' superior between bearings, external gear design offers the benefits of pulse-free operation, dry-run capability and ease of maintenance.

- Variety of mounting arrangements

- Horizontal and vertical suction discharge openings

- Stuffing box accommodates packing or mechanical seals

- Minimal shaft deflection

- Reduced bearing loads and shaft deflection

- Accurate alignment with two-piece doweled construction

- Reduced wear rates

- Prolonged service life

- Efficient operation over a broad range of speeds, pressures and viscosities

- No speed reducers

- Only one coupling guard

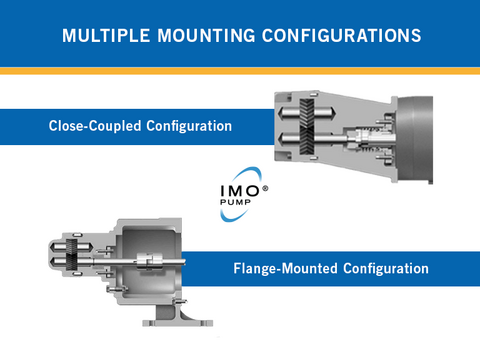

Multiple Mounting Configurations

The cast iron GA Series pumps are available in three mounting configurations foot-mounted, flanged and close-coupled. With its multiple options and modular design, GA Series pumps can be customized to satisfy a wide range of applications.

- GAS: Foot-mounted

- GAF: Flange-mounted

- GAC: Close-coupled

AVAILABLE OPTIONS

- Integral safety relief valve provides short-term emergency bypass

- Mechanical seal ensures positive sealing

- Mechanical seal with inboard shaft bearing for belt, chain or overhung gear drives

- Bronze sleeve bushings for dirty fluid applications

- Double helical, herringbone gears

- Quiet, pulse-free flow

- High-speed pump capability with off-the-shelf motors

- Between bearings design

- Self-lubricated babbitted carbon sleeve bearings standard; bronze bearings optional

- Hydraulically balanced design requires no thrust bearings

- Convertible stuffing box accommodates packing or mechanical seals

- Threaded ports

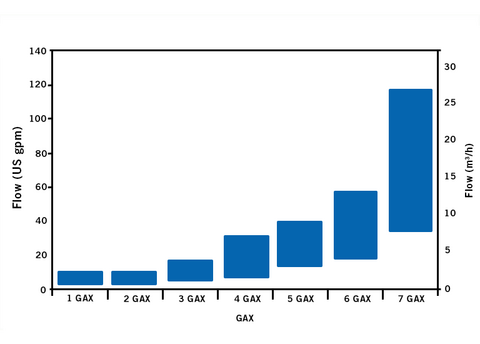

GA series Quick Selection Chart

For a quick selection of the GAX pump model corresponding to the desired flow rate, refer to the chart above. The ranges shown are based on typical viscosities and speeds and assume a zero differential pressure.

The chart's purpose is to direct the user to the appropriate performance curve, not to be a substitute for it