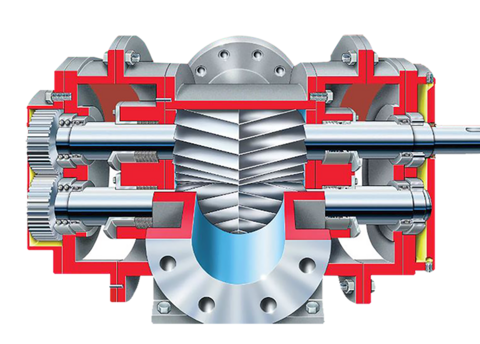

IMO Gearex Series Herringbone Gear Pump

High Capacity Pumping with Precision and Quiet Power

Extremely rugged and unusually compact for its high capacity and range, the Gearex rotary pumps are generally compliant with AP/ 676, second edition. Precision machined herringbone pumping gears provide low vibration, pulseless discharge while timing gears quietly and evenly transfer power to the driven rotors, ensuring minimal wear and long life

High-Speed Performance,

Low Total Cost

- External Timing Gears evenly transmit power to the rotors while eliminating rotor contact and promoting long pump life.

- Between Bearings Design virtually eliminates shaft deflection, even under highly viscous loads.

- Split Bracket Construction facilitates maintenance.

- Heavy-Duty Ball and Roller Bearings support the rotating element to prevent contact with the housing, thus reducing wear on the rotors and the body bore.

- Externally Lubricated Bearing design is well suited for corrosive, erosive, non-lubricating and run-dry services.

- Conventional Packing and Glands are standard, but mechanical seals are easily accommodated.

- Standard Motor Speeds can be used, eliminating V-belt drives and gear reducers.

- High Carbon Steel Shafts are machined and ground to close tolerances for accurate fit, symmetrical clearance and precise alignment.

- Directly Connected to motors up to 1800 rpm, Gearex pumps do not require heavy foundations, belts or reduction gears.

No Contact Between the Pumping Gears

Gearex timing gears transfer power to the rotors quietly and evenly. This design prevents metal-to-metal wear, promotes long pump life and reduces maintenance costs. The timing gears also make it possible to build external design Gearex pumps in stainless steels.

Vertical Mounting Configurations*

- Submerged sump configuration cold oil handling

- Eliminates high suction lift

- Conserves floor space

- Ensures flooded suction without need for foot valves

- Pedestal configuration bolts to floor or wall and is ideal for commercial marine and navy service

- Conserves space

- Straight through flow

- All parts are easily accessible

Spilt Brackets Ease Maintenance

An option for external bearing pumps, split brackets are easily separated to facilitate seal maintenance. When seal service is required, the bearing half of the bracket can be removed, offering full access to individual mechanical seals.

Gearex Quick Selection Chart