Macerators

Efficient Solids Reduction

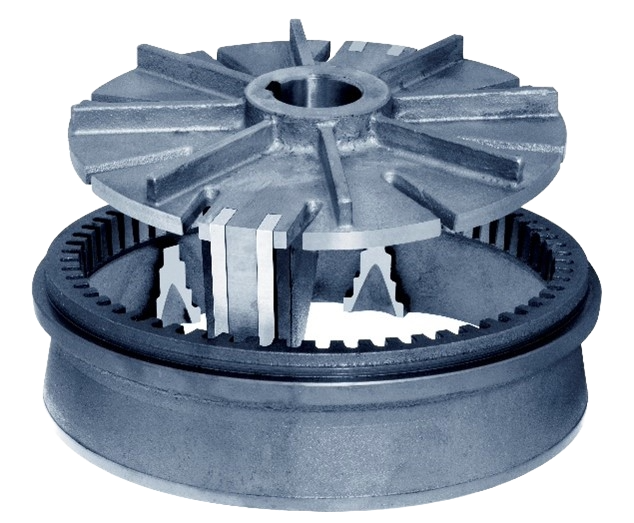

Allweiler macerators are the solution when it comes to size reduction of solids. They offer unsurpassed performance and efficiency when processing abrasive media, corrosive liquids and solids. The robust design guarantees reliable results even under extreme conditions. The macerators are versatile and optimize processes in various industries, e.g. wastewater, chemical or food. They are used to grind solids and produce pumpable liquids and feature a cutting wheel with replaceable, highly wear-resistant cutting elements.

Allweiler macerators are available in a variety of designs:

As collecting macerators for tanks/vessels with a static pressure head of up to 3 meters or also as in-line versions in combination with eccentric screw pumps for direct installation in pipelines.

Efficient Shredding

Highly wear-resistant cutting elements

Excellent Performance

Trouble-free handling of various fluids

Versatile Application

Solids, fibers, contaminants, and many more

Macerators

Smooth Process Optimization

Efficient crushing of solids ensures a continuous and efficient process flow, increasing throughput and minimizing production downtime. Avoiding clogging and blockages helps reduce maintenance time and maintain operations, increasing overall equipment effectiveness. As a result, the macerators support smooth, trouble-free operation, increasing your productivity and reducing your operating costs. The effects of this process optimization extend throughout the entire value chain and contribute to a sustainable increase in your operational efficiency.

Innovative cutting wheel technology

Maximum Efficiency & Minimal Clogging

The key to efficient solids reduction is the highly wear-resistant cutting wheel with replaceable cutting elements. By efficiently shredding and reliably conveying solids, macerators eliminate potential bottlenecks and blockages. This is especially important in demanding environments where solids and contaminants can threaten smooth operation. Our macerators ensure continuous processing of solids while producing a homogeneous, pumpable liquid that moves easily through the conveying line.

Macerators

Handle Extreme Conditions Easily

ALLWEILER macerators easily meet the challenges of processing abrasive and corrosive media, as well as liquids with high solids content. Their rugged construction is designed to deliver reliable results in extreme conditions. This makes them a durable and reliable solution for your demanding industrial or marine applications. Because of their characteristics, the macerators are able to provide consistent and efficient performance even in environments with aggressive or difficult media. You can count on the macerators to reliably process solids and make liquids pumpable, even under difficult conditions.

| Series | Specifications | Max. Capacity [m³/h] |

Max. Delivery Head [m] |

Max. Fluid Temperature [°C] |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AM |

|

|

|

80 | ||||||

| ABM |

|

80 |

|

80 |

*Delivery Head 9 ft / 3 m