FE Flexi-Shaft

Solutions For Lithium Battery Production

The FE Progressing Cavity Pump from Allweiler is specifically designed to minimize the risk of fluid contamination and provide an efficient solution for the transfer of lithium slurry.

The pump is characterized by reduced forces on hydraulic and mechanical components and is ideal for handling shear-sensitive, abrasive and viscous liquids. In addition, the pump offers reversible flow (CW and CCW) and pulsation-free fluid flow, further increasing efficiency and reliability in critical applications.

No Liquid Contamination

Efficient Lithium Sludge Transfer

Pulsation-Free

Keep operations flowing

Maximum efficiency and protection of sensitive liquids

The flexi-shaft design was engineered to avoid contamination of the pumped fluid. Beyond that, the FE design is optimized to reduce the forces on the pump’s hydraulic (rotor & stator) and the mechanical components like seals and bearings. This leads to lower impact on the pumped fluid and makes the pump suitable for various difficult, shear-sensitive, abrasive, and low to high viscose fluid handling applications or create a separate paragraph with this content. Due to the lower forces and the design of the Flexi-Shaft PC Pump the sealing is tight and avoiding leckage.

The flow is proportional to the speed so that the flow can be easily controlled via an optional VFD (Variable Frequency Drive). Further it is capable to be operated either CW or CCW so that the direction of flow is reversible.

Due to the design of the closed cavities between rotor and stator, the fluid is released smoothly and is pulsation free.

FE Flexi-Shaft

How it works

Allweiler´s FE Progressive Cavity Pump (PC Pump) is designed to eliminate the risk of fluid contamination while providing an efficient solution for fluid handling in mission critical and severe applications like the transfer of Lithium slurry and similar products in battery production.

By replacing the typical pin joints with an optimized flexi-shaft, the FE solution becomes a maintenance free solution related to joints with overall less wear parts and lower service and repair time. To further improve the serviceability, the design is set up in that way, that major wear parts like the stator and rotor can be exchanged individually without the need to overhaul the whole pump.

Features

Engineered To Meet Demands & Exceed Expectations

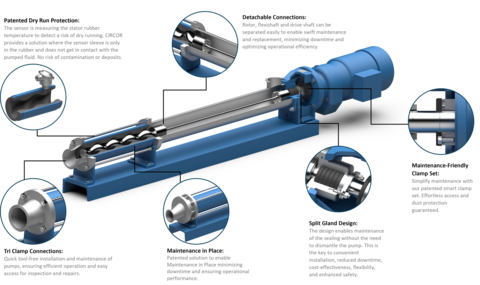

We offer additional options to upgrade the FE Progressing Cavity Pump with the following patented options:

Dry run protection: Integrated into the stator

The sensor is measuring the stator rubber temperature to detect a risk of dry running. CIRCOR provides a solution where the sensor sleeve is only in the rubber and does not get in contact with the pumped fluid.

Maintenance in Place solution

The design can be adjusted to enable stator and rotor replacement without the need to separate the pump from the installation.

Performance Data

| Flow Rate: | Up to 30 m³/h |

| Pressure: | Up to 12 bar |

Material of Construction

| Casings: | Stainless Steel |

| Rotor & Wetted Parts: | Stainless Steel / Duplex Stainless Steel |

| Stator: | EPDM, NBR, FKM, other materials on request |

Pump Design

| Closed coupled block design, Bearing frame design |

Options

| Sealing: | Gland Packing, Mechanical Seal |

| Rotor: | Chrome Coating |

| Accessories: | Dry run protection, Pressure Sensor, VFD |