Hopper Pump Series

Efficient Wastewater Pumping Due To Optimized Hopper Design

Allweiler's hopper pumps offer excellent performance and reliability for handling viscous, abrasive or solids-laden materials in various industrial applications, such as the wastewater industry. Their unique hopper design enables efficient and smooth product transfer in this tough environment. They handle non-free-flowing and highly viscous products in wastewater applications without dificulty, whether neutral or aggressive. Eccentric screw pumps in hopper design can easily handle products with fibrous or solid components. These rugged hopper pumps can handle a dry solid content of up to 45 %.

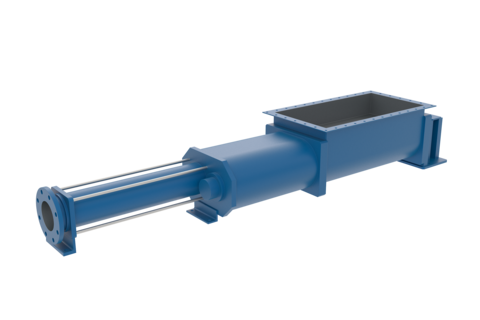

Flat Design

Highly viscous media

Pulsation-Free

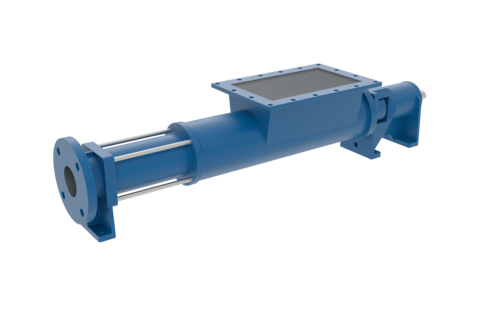

The hopper pumps are designed for highly efficient pumping of wastewater and solids-laden media. Due to the funnel-shaped inlet, smooth pumping without turbulence and clogging can be provided. Large inlet hoppers provide ample space to accommodate large volumes of wastewater and solids-laden media. This ensures continuous, high-volume flow without bottlenecks. The inside of the hopper is smooth and free of sharp edges or obstructions. This prevents sedimentation and buildup of solids in the wastewater that could impede flow.

Allweiler hopper pumps are designed for easy cleaning and maintenance. The pumps' smooth surfaces and thoughtful design allow for efficient cleaning without leaving residue or contamination in hard-to-reach areas. In addition, our hopper pumps are designed to be maintenance friendly. This minimizes downtime and keeps your plant running smoothly.

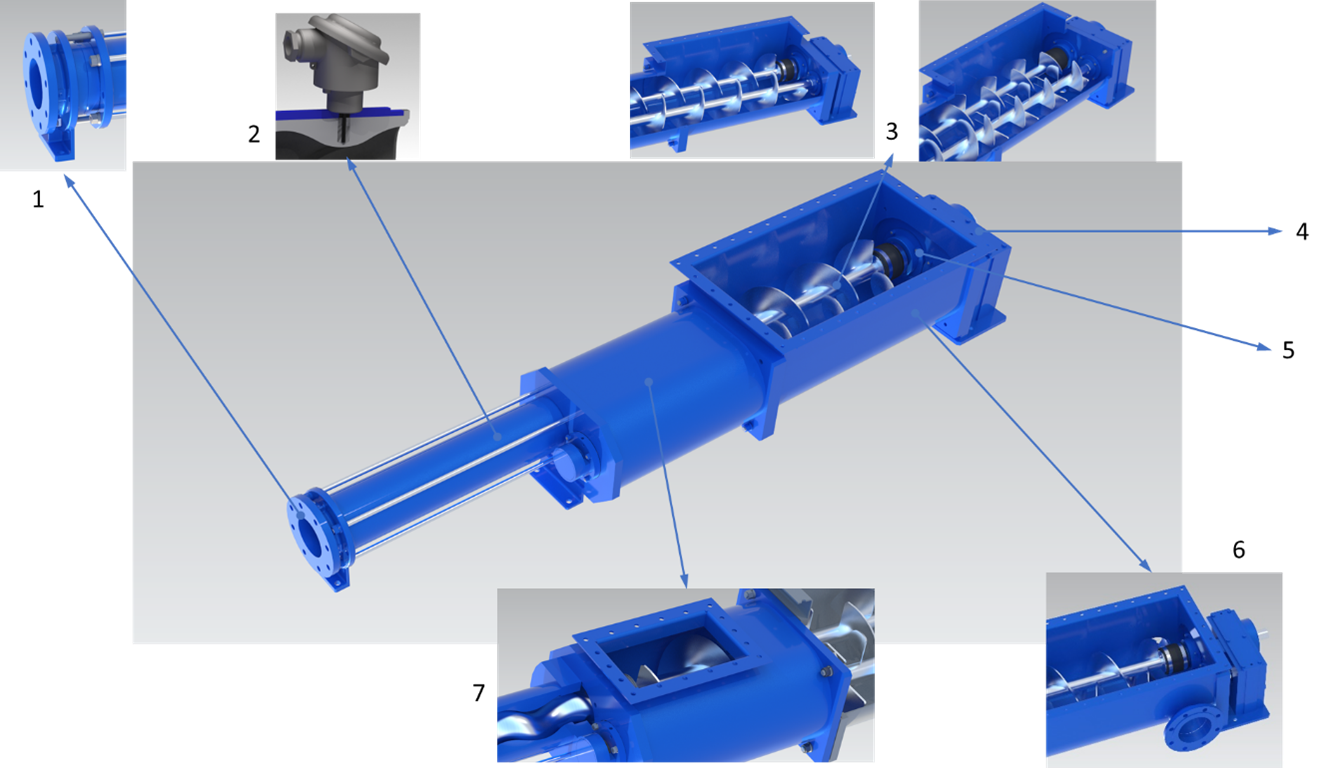

AE-RG hopper pump from Allweiler

Revolutionary Design, Unmatched Reliability

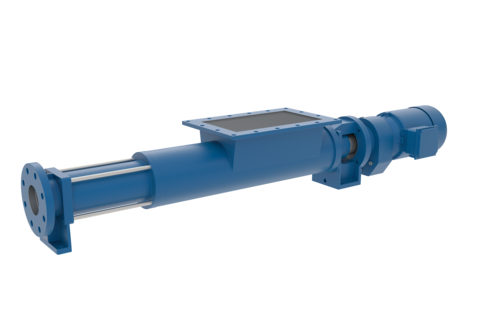

The unique design of the AE-RG hopper pump is unsurpassed and offers many advantages to the operator. The optimally dimensioned and designed inlet hopper reliably prevents buildup of the pumped material. In combination with the two intermeshing augers, bridging or clogging of the feeding line is impossible.

A special feature of the Allweiler hopper pump is that it does not require any additional equipment such as an attached bridge breaker or other mixing elements. This ensures continuous pumping of dewatered slurries or other highly viscous fluids with a dry solid content of up to 45 % without significant downtime.

Another advantage is the low overall height of the AE-RG, which allows for easy and space-saving integration into your plant. A maintenance-free mechanical face seal is used for sealing, which is a perfect complement to the Allweiler hopper pump.

- A Maintenance-in-Place solution for the RG series is available. With the features in place, service can be done without pulling the pump out of the installation.

- Our patented dry run protection is also available for the RG series.

- Different auger designs available to fit best for your applications.

- Robust gearbox and bearing design for a long lifetime and less downtime.

- Smart auger-shaft / driveshaft connection for easier maintenance.

- Cleaning / Flushing ports in inlet casing for easier cleaning and inspections.

- Cleaning port in stuffing casing makes inspection & cleaning very easy.

AEB-ZE/AE-ZD

Efficient Pumping Without Breakdowns

Allweiler Z-hopper pumps are equipped with a screw conveyor and are particularly suitable for highly viscous and abrasive media with a dry solids content of up to 20 %. The special design of the feed hopper reliably prevents deposits and bridging. The design of the feed screw and stuffing chamber was aimed at providing a solution that allows continuous pumping while preventing clogging. In this way, Allweiler pumps ensure continuous operation without downtime.

| Series | Specifications | Max. Capacity [l/min] |

Max. Differential Pressure [bar] |

Max. Fluid Temperature [°C] |

Max. Solid Content [%] |

Max. Viscosity [mm²/s] |

Max. Stages |

|---|---|---|---|---|---|---|---|

| AEB-ZE | Block Design | 750 | 24 | 100 | 20 | 1,000,000 | 4 |

| AE-ZD | Bearing Design | 1,700 | 36 | 135 | 20 | 1,000,000 | 4 |

| AE-RG | Bearing Design | 500 | 24 | 135 | 45 | 1,000,000 | 6 |