AEB-DE® Series

Four Pump Sizes, One Installation Size & Diverse Possibilities

Dosing and handling high-viscosity, solids-laden fluids require an eccentric screw pump that can ensure high efficiency and trouble-free operation. Nowadays, customers expect more from pump manufacturers than just stable pump performance and precise metering capabilities. They are looking for pump suppliers who can deliver traditional quality and reliability, combined with cost-effective pricing and reasonable lead times.

The next generation of Allweiler AEB-DE® dosing pumps deliver all of this. We have combined proven and durable features from our proven industrial pump range with optimized rotor and stator geometries to ensure the highest dosing accuracy. The added value of this new series sets a new standard for flexible installations.

Space-Saving

Modular System

4 pump sizes

with identical foot print

High Efficiency

& Metering Accuracy

New optimized rotor

and stator geometry

Universal

Application

Bidirectional operation

possible

Flexible

Installation Options

Horizontal and vertical

installation possible

Pump Flexibility With No Limits

The AEB-DE® Series Revolutionizes Skid Design!

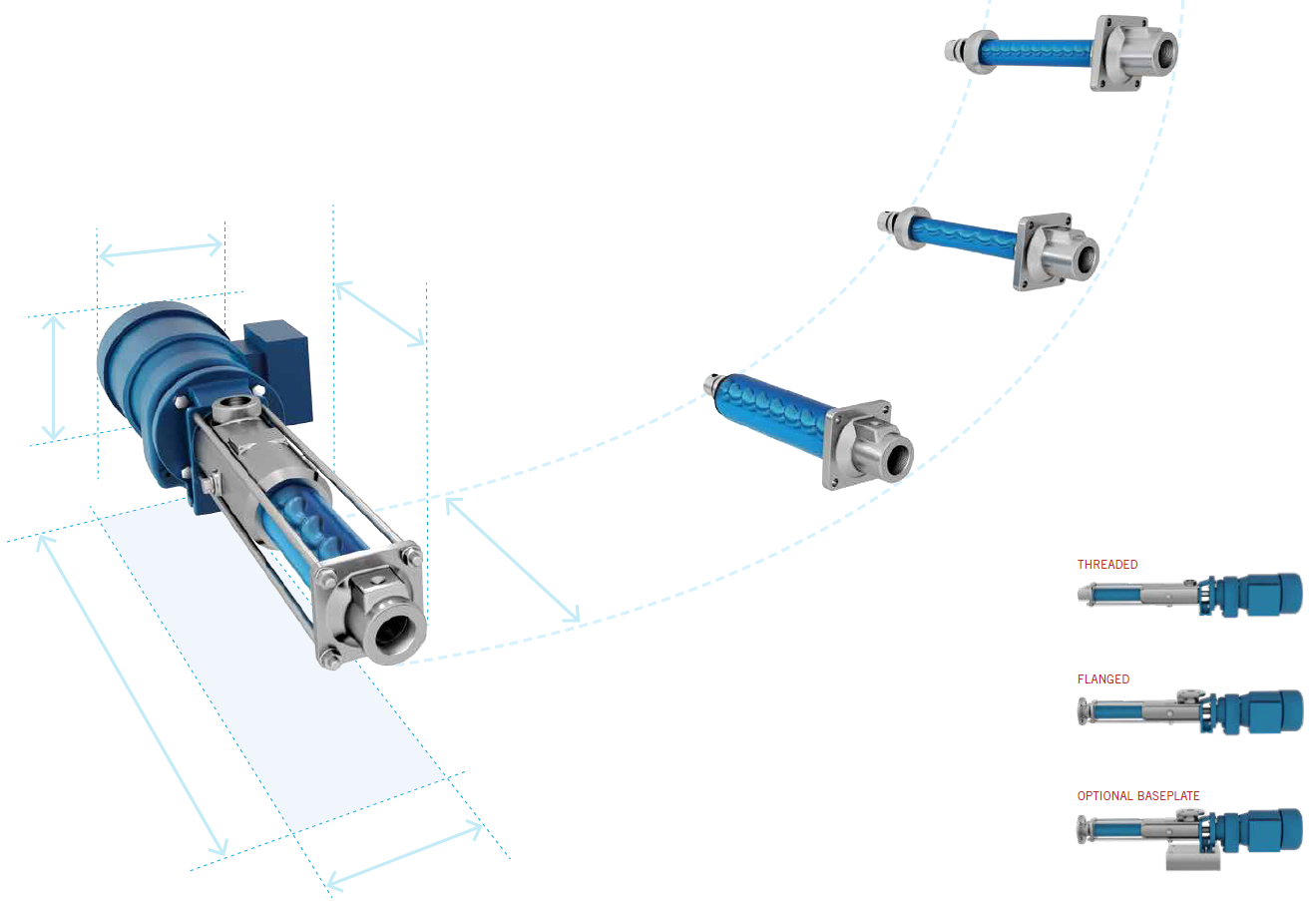

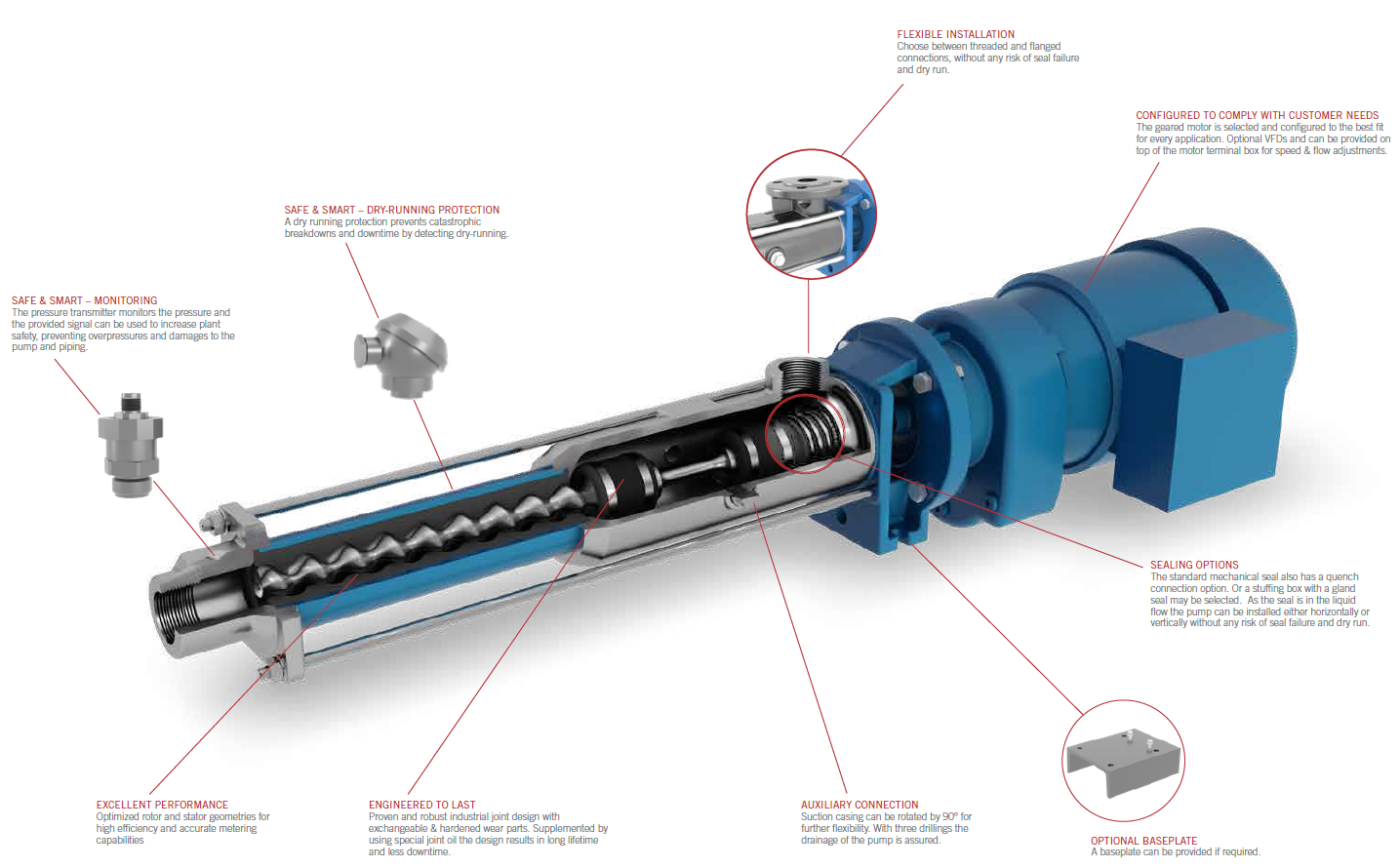

The modular design of the AEB-DE® Series allows skid builders to standardize their designs regardless of flow rate and fluid characteristics. A compact modular design easily adapts to skids. Skid builders simply equip the installation space according to the specified operating data for the specified pump. Four pump sizes with identical external dimensions are available to meet user requirements and are suitable for bi-directional flow. This flexibility allows for future changes in required flow rates by simply changing the conveying elements. No costly rebuilds or adjustments to the pipeline are required.

Versatility & Protection

The Innovative Suction Casing of the AEB-DE® Series

The innovative design of the new suction casing features three additional closed holes that can be used for different functions. Customers can fill, drain, or install additional accessories as needed. In addition, the new casing design provides continuous flushing and cooling of the seal because it is in the liquid stream. This allows the pump to be installed vertically without the risk of damaging dry running. If required, a quench connection can be offered as a sealing option, or the pump can be equipped with a stuffing box packing. To ensure safe operation of the system and to prevent pump failure or damage, the AEB-DE® series can be upgraded with an intelligent dry run protection (ATLS-T1) or a pressure sensor (ATLS-P).

AEB-DE® for a Wide Range of Dispensing Applications

The versatile and compact AEB-DE® pump series is suitable for a wide range of viscosities, flow rates and temperatures and reliably provides high volumetric efficiency. The geared motor is selected and configured to best suit the application. Optional VFDs can be mounted on top of the motor terminal box to adjust speed and flow. The geometry and design details of key components have been optimized to further improve metering accuracy and performance curve stability. High-quality stainless-steel material allows the pumps to cover even more applications than before, including water and wastewater, pulp and paper, marine, chemical and mining, among others.

| Series | Specifications | Max. Capacity [l/min] |

Max. Differential Pressure [bar] |

Max. Fluid Temperature [°C] |

Max. Viscosity [mPas] |

Max. Permissible Proportion of Solids [v%] |

|---|---|---|---|---|---|---|

| AEB-DE | Block Design | 33 | 24 | 100 | 28.000 | 60 |