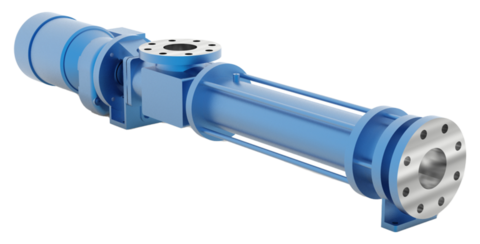

OPTIFIX™ Series

Performance Without Compromise, Maintenance in No Time

Allweiler OPTIFIX™ Progressing Cavity Pumps are the answer to your need for reliable pumps that don't compromise on performance, yet are quick and easy to service. Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR).

The Allweiler OPTIFIX™ pump features a compact block design and is suitable for a wide range of fluids. Whether you are pumping neutral or corrosive fluids, whether your fluid is clean or contains abrasive components, whether it contains gases or tends to foam, whether it is low or high viscosity, this progressive cavity pump can handle the job.

Less Maintenance

Shorter Down Time

Lower Service Costs

OPTIFIX™ & ALLDUR®

Maximize Your Pump's Service Life

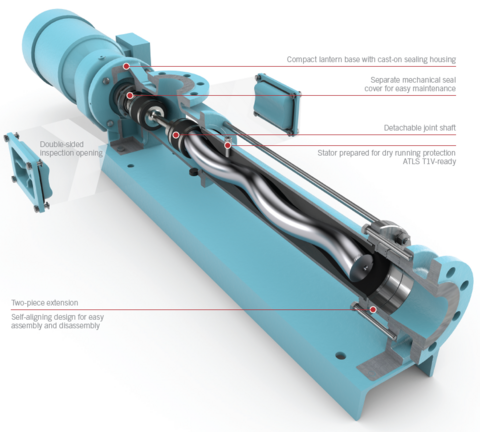

Designed for speed and efficiency, the OPTIFIX™ quick-change system makes it safe and easy to replace wear parts and perform maintenance.

And when you equip your pump with an ALLDUR® stator, you can extend service life by up to 500 % – dramatically reducing your life cycle costs.

OPTIFIX™

Maximum Efficiency with Minimum Downtime*

Every second counts when it comes to maintaining progressing cavity pumps. Allweiler OPTIFIX™ Progressing Cavity Pumps are designed to make maintenance faster, less frequent and easier than ever before. Breakthrough features such as the patented zero-backlash stub shaft connection and high quality joint design allow the pump to be serviced, repaired or upgraded in a fraction of the time normally required. The OPTIFIX™ features a specially designed removal tool that allows the stator and rotor to be removed without removing the discharge or suction casing from the piping. This gives the OPTIFIX™ the best MTTR (Mean Time To Repair) in its class. And to make it even faster, we also offer pre-assembled replacement kits that make maintenance even easier.

*Compared to conventional Allweiler designs

The optimized and maintenance-friendly design does not affect the life of the rotor and stator.

No compromise in efficiency and flow.

Compact design and reduced installation space allow greater installation flexibility than ever before.

Optimized sealing protects against leakage, eliminating contamination problems during disassembly and assembly.

The optimized seal and self-centering removal piece between the stator and pressure housing facilitate cleaning, assembly and maintenance, reducing the risk of downtime.

| Series | Specifications | Max. Capacity [l/min] |

Max. Discharge Pressure [bar] |

Max. Fluid Temperature [°C] |

Max. Viscosity [mm²/s] |

|---|---|---|---|---|---|

| AEB-MF | Maintenance in Place Blockdesign | 1.600 | 10 | 100 | 190.000 |