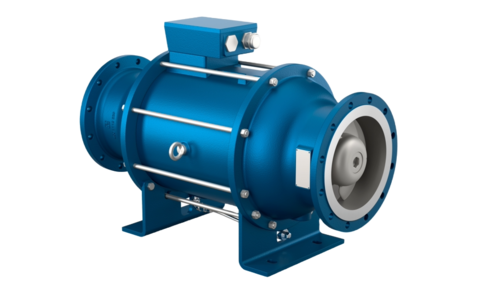

ALLTRIMM® Series

Space-Saving Power for Your Anti-Heeling-System

Anti-Heeling-Systems keep ships in balance during loading and unloading. The ALLTRIMM® is an innovative inline propeller pump, also known as axial flow pump, designed specifically for use in Anti-Heeling-Systems.

The pump features reversible hydraulics and an integrated drive, eliminating the need for complex valve controls. The ALLTRIMM® is driven by an electric motor that is cleverly integrated into the pump hub. The compact and space-saving design allows the pump to be easily mounted between two flanges in the pipeline without the need for a separate foundation.

Compact & Extremely Space Saving

By integrating the drive into the pump

Reversible Hydraulics

Flow in both directions

Low Maintenance

Compact Design & Space-Saving Efficiency

With the ALLTRIMM® Propeller Pump, you can reduce your installation effort and costs. By integrating the drive into the pump and eliminating additional valves and piping, ALLTRIMM® axial flow pumps require less space than conventionally designed anti-heeling systems, saving valuable engine room space. The inline design allows for easy installation without a foundation. The drive does not require additional internal cooling air, as it is cooled directly by the water being pumped. In addition, the pump can be started and stopped without risk of overheating.

Optimized Reversible Hydraulics

Efficient Ballast Tank Filling

Our ALLTRIMM® propeller pumps are equipped with powerful reversible hydraulics that ensure equal filling of your ballast tanks in both pumping directions. This means maximum efficiency and reliability no matter which direction you pump.

Efficiency, Reliability, and Minimal Maintenance

The economic efficiency of the ALLTRIMM® propeller pump is characterized by long maintenance intervals and low maintenance requirements. This is because the pump operates without cost-intensive wear parts such as couplings or gears.

Another advantage of the design concept is that the low mass moments of inertia of the few rotating parts allow for low-load and fast reversal of flow direction as well as very short start-up times. Finally, integrated leakage monitoring ensures safe operation. Wear is detected automatically and at an early stage so that maintenance can be planned.

| Series | Specifications | Max. Capacity [m³/h] |

Max. Delivery Head [m] |

Max. Differential Pressure [bar] |

Max. Fluid Temperature [°C] |

No. of Stages |

|---|---|---|---|---|---|---|

| ALLTRIMM® |

Inline propeller pump symmetrical performance data |

1,400 | 20 | 2.5 | 40 | 1 & 2 |