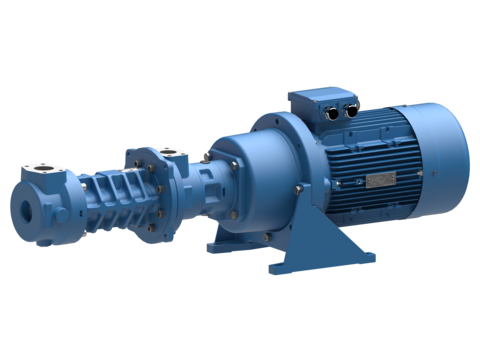

EMTEC® Series

Coolant Delivery at High Pressure

The Allweiler EMTEC® series is the optimal solution for high-pressure coolant supply in machine tools. The three-screw pump is an essential element in the effective distribution of coolants and protective agents in metalworking, on transfer lines as well as grinding and deep drilling machines up to 100 bar.

Thanks to its advanced design, it allows safe handling of abrasive media, resulting in minimum downtime and maximum equipment availability. The use of high-quality materials and precise technology ensures durable and reliable operation even in demanding conditions.

Longer Service Life

Designed for the harsh environment of the

high-pressure coolant circuits in machine tools

Higher Efficiency

Finest tolerances through state-of-the-art manufacturing technology

Lower Pulsation

Only 1 - 2 % of the delivery pressure

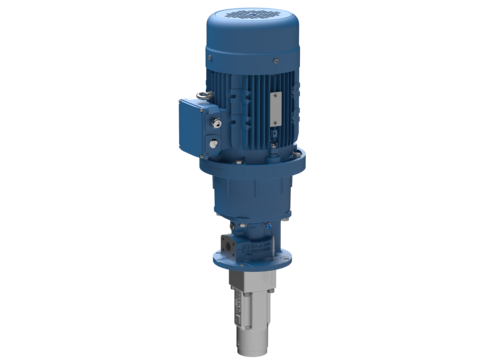

Advanced Technology for Longer Service Life

EMTEC® three-screw pumps are specifically designed for the harsh environment of the high-pressure coolant circuit in machine tools. Special hardening processes create a ceramic-like surface hardness in the housing bores while maintaining elasticity. This reduces the risk of surface damage. Highly wear-resistant spindles are hardened for long service-life.

EMTEC®: Engineering for Peak Efficiency

State-of-the-art manufacturing processes allow extremely tight tolerances to be maintained, preventing backflow of the low-viscosity coolant, resulting in very high efficiencies. The drive spindle balance piston is extra-long to improve volumetric efficiency. The fluid flowing over the balance piston serves to cool and lubricate the sealing surfaces of the silicon carbide mechanical seal.

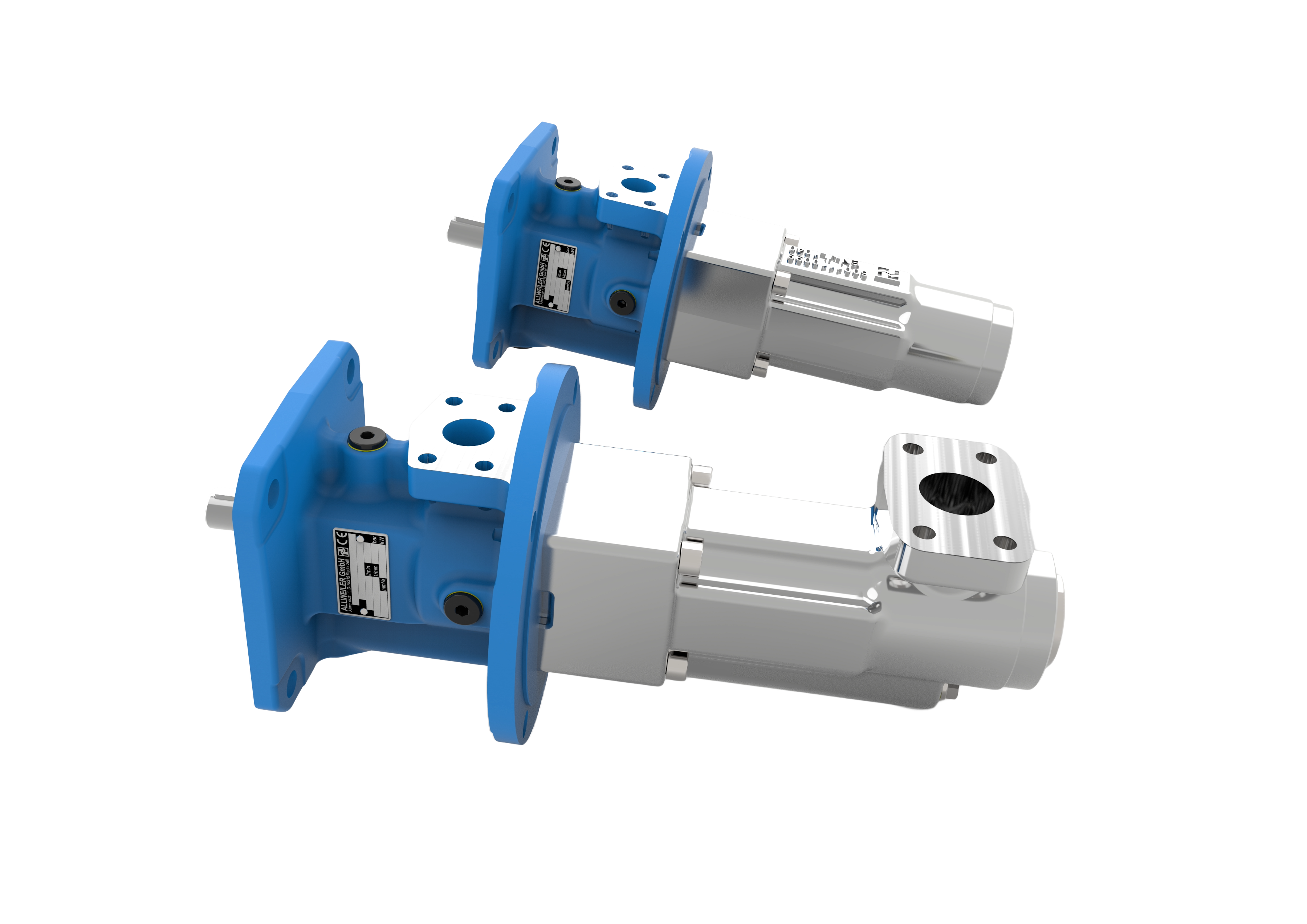

EMTEC®-C: Making a good pump even better.

We have used our unparalleled industry experience to develop the innovative EMTEC®-C. The EMTEC®-C is a maintenance-friendly three-screw pump, manufactured using unique technology and the highest quality materials, offering even greater durability and efficiency in the flow range of 10-80 l/min. Different sizes and screw pitches are available to match capacities requirements across the range.

| Series | Specifications | Max. Capacity [l/min] |

Max. Inlet Pressure [bar] |

Max. Outlet Pressure [bar] |

Max. Fluid Temperature [°C] |

Viscosity Range [mm²/s] |

|---|---|---|---|---|---|---|

| EMTEC®-A DQ |

Shaft seal ring |

1,000 | 1 |

100 (Emulsion) 120 (Oil) |

80 | 1-2,000 |

| EMTEC®-A D8.6 |

SiC/SiC mechanical seal |

1,000 | 10 |

100 (Emulsion) 120 (Oil) |

80 | 1-2,000 |

| EMTEC®-C Q |

Shaft seal ring |

80 | 0,2 | 100 | 80 | 1-760 |

| EMTEC®-C 19US |

SiC/SiC mechanical seal |

80 | 6 | 100 | 80 | 1-760 |