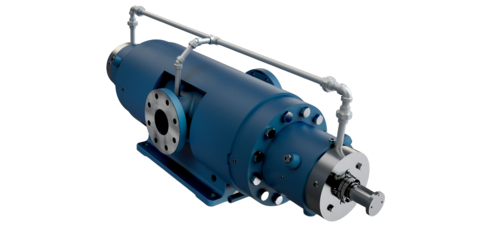

IMO 324A Series

MFG in Monroe, NC USA

Series C324A is a double suction design providing relatively high flow rates in a compact pump. These are commonly used for machinery lubrication, fuel oil transfer and burner services and for asphalt and vacuum tower bottoms processing and transfer. Pumps are available with optional steel casings with or without steam/hot oil jacketing.

Three-Screw Pumps

The Superior Pumping Technology

Discover our three-screw pumps - the clear choice for superior performance and versatility. The unique design with three interlocking spindles provides an extremely efficient and smooth flow, resulting in impressive overall efficiency.

In addition to excellent controllability, the self-priming pumps offer minimal pulsation and remarkably quiet operation, even at high discharge pressures.

Our three-screw pumps are true all-rounders, capable of handling a wide range of fluids of varying viscosities - from low-viscosity fluids to highly viscous substances. It’s robust design and the high wear resistance of the spindles ensure reliability and long life, making them the ideal choice for critical applications in a variety of industries.

- Series 324A pumps are of the double suction design

- Completely mounted pump/driver assemblies with baseplates

- Double extended shaft versions available for through-drives

Series 324A is a double suction design providing relatively high flow rates in a compact pump. These are commonly used for machinery lubrication, fuel oil transfer and burner services and for asphalt and vacuum tower bottoms processing and transfer. Pumps are available with optional steel casings with or without steam/hot oil jacketing.

This 324A series is available in

Nominal flow rate, GPM/LPM, at 500 PSI (34.5 BAR), 200 SSU (43 CST)

SPEED RPM

|

324A Series |

3500 |

2900 |

1750 |

1450 |

1150 |

960 |

|

162 |

101/382 |

81/307 |

43/162 |

33/125 |

23/87 |

17/63 |

|

187 |

158/598 |

128/483 |

69/261 |

54/203 |

38/146 |

29/109 |

|

231 |

304/1149 |

246/933 |

137/517 |

108/409 |

79/300 |

61/232 |

|

250 |

- |

314/1189 |

176/664 |

139/527 |

103/390 |

80/304 |

|

275 |

- |

- |

238/900 |

190/718 |

142/536 |

111/420 |

|

300 |

- |

- |

314/1187 |

251/950 |

188/713 |

149/563 |

|

325 |

- |

- |

404/1528 |

324/1227 |

245/926 |

194/735 |

|

350 |

- |

- |

510/1928 |

410/1552 |

311/1177 |

248/939 |

|

375 |

- |

- |

632/2393 |

510/1931 |

388/1469 |

311/1176 |

|

412 |

- |

- |

851/3222 |

688/2607 |

526/1992 |

423/1602 |

Maximum Speed- Do not exceed 1,800 RPM pumping residual fuels or crude oil due to the presence of abrasives and contaminants:

| Size | 162 | 187 | 231 | 250 | 275 | 300 | 325 | 350 | 375 | 412 |

| RPM | 4200 | 4200 | 3600 | 3000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

* Assumes minimum inlet pressure requirements are met.

Construction features

Iron or steel case, Dry installation, Horizontal installation, Self priming, Packing or Mechanical shaft seal, Thermal jacketing option

Other data

Design standard: Manufacturer STD

Fluids: Fuel Oils, Lubrication Oils, Oils > Crude Oil

Sealing: Packing, Single Mechanical seal

Capacity up to: 900 gpm

Pressure up to: 500 psiD

Viscosity range: 32 to 3,500 ssu

Speed up to: 1,800 rpm

Max. gpm: 900.00

Max. lpm: 3,406.87

Max. m³/hr: 204.41

Max. bar (dp): 34.47

Max. psi (dp): 500.00

Pressure Class (ANSI): 125, 250, 300

Max. cSt [mm²/s]: 5,397.50

Max. SSU: 25,000.00

Min. cSt [mm²/s]: 7.30

Min. SSU: 50.00

Max. °C: 260.00

Max. °F: 500.00

Min. °C: -18.00

Min. °F: 0.00