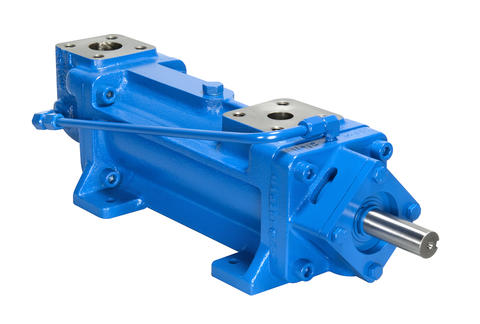

IMO 6D Series

MFG in Monroe, NC USA

Series 6D IMO® pumps are intended for high pressure service on fluids with viscosity from 2 cSt to 25,000 ssu. Typical applications include crude oil pipeline service, fuel atomization for combustion gas turbine fuel injection, fluid power service on hydraulically operated machinery, gas sealing in centrifugal compressors and hydrostatic bearing support.

These pumps are hydraulically balanced in both the axial and radial directions, which eliminates bearing loads due to differential pressure. The single grease packed ball bearing is external to the liquid pumped and does not rely on the lubrication qualities of the pumped liquid. The single mechanical seal is exposed only to inlet pressure. Very low airborne noise levels are normal for IMO® three-screw positive displacement pumps as are high operating efficiencies and non-pulsating delivered flow.

Three-Screw Pumps

The Superior Pumping Technology

Discover our three-screw pumps - the clear choice for superior performance and versatility. The unique design with three interlocking spindles provides an extremely efficient and smooth flow, resulting in impressive overall efficiency.

In addition to excellent controllability, the self-priming pumps offer minimal pulsation and remarkably quiet operation, even at high discharge pressures.

Our three-screw pumps are true all-rounders, capable of handling a wide range of fluids of varying viscosities - from low-viscosity fluids to highly viscous substances. It’s robust design and the high wear resistance of the spindles ensure reliability and long life, making them the ideal choice for critical applications in a variety of industries.

- Intended for relatively high-pressure service on petroleum or similar viscosity liquids

- Hydraulically balanced in both axial and radial directions to eliminate bearing loads due to discharge pressure

- Inlet is rotatable in 90° increments for ease of piping

- Low noise, high efficiency, non-pulsating delivery

Series 6D is a medium pressure pump line finding extensive use on fuel oil burners, high pressure trunion lubrication for ball mills, crude oil pipeline service and non-cyclic hydraulic applications.

This 6D series is available in:

Nominal flow rate, GPM/LPM, at 1500 PSI (103 BAR), 200 SSU (43 CST)

SPEED RPM

|

Series 6D Size

|

3500 |

2900 |

1750 |

1450 |

1150 |

960 |

|

106

|

12/44 |

9/34 |

- |

- |

- |

- |

|

118

|

17/65 |

13/50 |

6/23 |

- |

- |

- |

|

137

|

28/106 |

22/83 |

10/38 |

7/26 |

- |

- |

|

156

|

42/160 |

33/125 |

16/61 |

12/45 |

- |

- |

|

187

|

76/287 |

60/227 |

31/117 |

24/91 |

16/61 |

- |

|

218

|

123/466 |

99/375 |

52/197 |

40/151 |

28/106 |

20/76 |

|

250

|

187/708 |

151/572 |

82/310 |

64/242 |

45/170 |

34/129 |

|

275

|

- |

207/783 |

114/431 |

90/341 |

66/250 |

51/193 |

|

312P

|

- |

- |

135/511 |

107/405 |

79/299 |

61/231 |

|

312

|

- |

- |

174/659 |

138/522 |

103/390 |

81/307 |

|

350

|

- |

- |

251/950 |

201/761 |

151/572 |

120/454 |

|

400P

|

- |

- |

303/1147 |

244/924 |

184/696 |

147/556 |

|

400

|

- |

- |

385/1457 |

311/1177 |

237/897 |

190/719 |

Maximum RPM*

| Size | 106 | 118 | 137 | 156 | 187 | 218 | 250 | 275 | 312P | 312 | 350 | 400P | 400 |

| RPM | 5400 | 5400 | 4400 | 4400 | 4400 | 3600 | 3600 | 3000 | 2500 | 2500 | 2500 | 2500 | 2500 |

Construction features

Iron or steel case, Dry installation, Horizontal or vertical installation, Self priming, Mechanical shaft seal

Other data

Design standard: Manufacturer STD

Fluids: Fuel Oils, Lubrication Oils, Oils > Crude Oil

Sealing: Single Mechanical seal

Capacity up to: 400 gpm

Pressure up to: 1,500 psiD

Viscosity range: 32 to 3,500 ssu

Speed up to: 3,600 rpm

Max. gpm: 400.00

Max. lpm: 1,514.16

Max. m³/hr: 90.85

Max. bar (dp): 103.42

Max. psi (dp): 1,500.00

Pressure Class (ANSI): 125, 250, 300, 600, 900

Max. cSt [mm²/s]: 5,397.50

Max. SSU: 25,000.00

Min. cSt [mm²/s]: 2.10

Min. SSU: 33.00

Max. °C: 121.00

Max. °F: 250.00

Min. °C: -18.00

Min. °F: 0.00