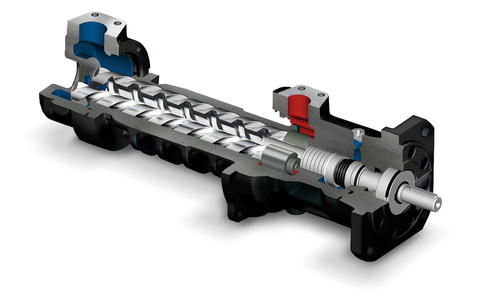

IMO LB6D Series

WORKHORSES IN THE OILFIELD

Made in Germany

IMO is one of the leading three-screw pump technology brand in the pump industry today. You get all the advantages that matter most to you: longer life, lower pressure ripple, lower contamination sensitivity and maximum energy savings, which results in the highest Total Savings of Ownership across the entire life cycle of your pumping equipment solution.

IMO 3-screw technology is installed in hundreds of high-pressure pipeline applications around the world. Beyond their substantial functional excellence, the pumps’ simple design provides maintenance advantages that further enhance their value in critical applications.

IMO 3-screw pumps have a simple design with only three rotating parts, pulse-free flow with extremely low vibration and noise levels, and high-pressure boost capabilities, even when handling low-viscosity fluids.

Three-Screw Pumps

The Superior Pumping Technology

Discover our three-screw pumps - the clear choice for superior performance and versatility. The unique design with three interlocking spindles provides an extremely efficient and smooth flow, resulting in impressive overall efficiency.

In addition to excellent controllability, the self-priming pumps offer minimal pulsation and remarkably quiet operation, even at high discharge pressures.

Our three-screw pumps are true all-rounders, capable of handling a wide range of fluids of varying viscosities - from low-viscosity fluids to highly viscous substances. It’s robust design and the high wear resistance of the spindles ensure reliability and long life, making them the ideal choice for critical applications in a variety of industries.

- 3 Frame Sizes / 6 Displacements

- Gas nitride hardened and PVD coated rotor set

- Ductile iron casing components

- Thermochemically hardened rotor housing tri-bore

- Hydrodynamic design

- Hydraulically balanced rotor set

- Silicon carbide seal faces (rotating and stationary)

- Fluorocarbon elastomer

- SAE Code 61 (3,000 psi) port pads

Construction features

| Rotor Housing | Nodular Iron - basic hardness (62 HRC) surface hardness |

| Inlet Head | Nodular Iron |

| Discharge Casing | Nodular Iron |

| Power & Idler Rotors | Alloy Steel Gas Nitrided (62 HRC) and PVD hard coat |

| Mechanical Seal | Silicon carbide faces, fluorocarbon elastomer |

| Elastomer | Fluorocarbon |

| Capacity | 30 - 180 gpm / 1,000 - 6,200 BPD |

| Temperature Range | to 176 °F |

| Max Inlet Pressure | 100 psig |

| Max Differential Pressure* | 1,450 psi |

| Max Outlet Pressure* | 1,450 psig |

| Viscosity Range | 1.5 to 760 cSt |

*Maximum pressures are dependent on rotating speed and fluid viscosity. Contact factory for details.

Rotor Housing: Nodular Iron - basic hardness (62 HRC) surface hardness

Inlet Head: Nodular Iron

Discharge Casing: Nodular Iron

Power & Idler Rotors: Alloy Steel Gas Nitrided (62 HRC) and PVD hard coat

Mechanical Seal: Silicon carbide faces, fluorocarbon elastomer

Elastomer: Fluorocarbon