Tushaco Three-Screw Series

Made in India

Tushaco three-screw pumps are highly reliable, efficient and versatile pumps that are a popular choice in the Indian market for various industrial applications.

These pumps are designed with precision hydraulics to ensure outstanding performance and minimal operating costs. A notable feature is their self-priming capability, which enables them to handle a wide range of fluids and viscosities. The pumps are constructed of durable materials for long life and minimal downtime. They also require minimal maintenance, making them cost effective in industrial environments. By investing in Tushaco three-screw pumps, users can expect peak performance and reliability for their pumping applications that will exceed their expectations.

High Reliability

& Long Service Life

Low Noise & Vibration

High Efficiency

Low Maintenance

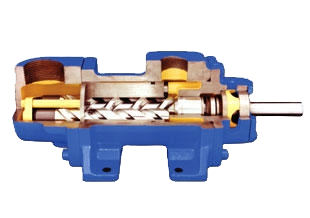

Three-Screw Pumps

The Superior Pumping Technology

Discover our three-screw pumps - the clear choice for superior performance and versatility. The unique design with three interlocking spindles provides an extremely efficient and smooth flow, resulting in impressive overall efficiency.

In addition to excellent controllability, the self-priming pumps offer minimal pulsation and remarkably quiet operation, even at high discharge pressures.

Our three-screw pumps are true all-rounders, capable of handling a wide range of fluids of varying viscosities - from low-viscosity fluids to highly viscous substances. It’s robust design and the high wear resistance of the spindles ensure reliability and long life, making them the ideal choice for critical applications in a variety of industries.

-

One power screw and two idler screws run in three precision bores in the body or liner.

-

Profiled screws form a liquid-tight seal between the threads.

-

As the screws rotate, they create cavities that trap liquid and move it from the suction chamber to the discharge chamber.

-

The power rotor does not rotate the idlers. The hydraulic forces acting on the screw flanks rotate the idlers without torque, reducing friction.

-

Idlers simply roll over the root diameter of the power screw and float freely in the housing/liner bores.

-

A balance piston on the Power Rotor provides axial thrust.

-

Ball bearings are used only for axial positioning of the rotor and safer operation of the mechanical seal.

| Series | Max. Capacity [m³/h] |

Max. Differential Pressure [bar] |

Max. Fluid Temperature [°C] |

Max. Viscosity [cSt] |

|---|---|---|---|---|

| T3ST | 2,835 | 40 | 200 | 760 |

| T3SI | 430 | 12 | 80 | 760 |

| T3SZ | 155 | 12 | 125 | 760 |

| T3SFP | 56 | 40 | 125 | 760 |