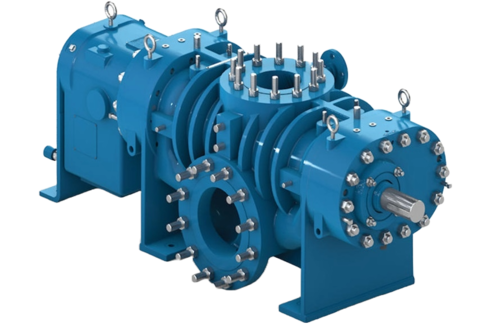

WARREN FSXA SERIES

WARREN FSXA SERIES PUMPS

The FSXA Series is a heavy-duty, high pressure twin screw pump suitable for applications where high efficiency and durability are critical: Integral rotors provide leading rigidity, limiting deflection and eliminating assembly failure points. Keyless timing gears and easy ‘pop-out’ rotor access for simple inspection and maintenance. Rugged design for the harshest environments

The FSXA Series is suitable for a host of applications within the production and transportation segments of the Oil and Gas market including platforms and pipelines. It is available in a variety of materials, including cast and stainless steel, to meet your specific requirements (i.e. NACE).

High performance meets high reliability

Ability to Handle Multiple Liquids at Multiple Viscosity Rates

Because they're designed to move fluid at a consistent rate, regardless of pressure, twin-screw pumps deliver results where centrifugal pumps are unable to and are able to actually increase efficiency as viscosity rises.

But twin-screw pumps don't just offer performance, since they are designed to eliminate metal-on-metal contact which means a longer life, improved reliability and less downtime.

In addition, unlike other pump options, twin-screw pumps can:

- Tolerate contamination

- Handle a large range of viscosities and fluids

- Low NPSH required

- Run dry

- Low fluid sheer

- Operate at variable speeds

And with twin-screw pumps' ability to handle multiple liquids at multiple viscosity rates, they can be used for a wide range of applications.

- Available in a variety of materials, including cast iron and stainless steel

- Integral rotors eliminate assembly failure points

- Keyless timing gears and easy ‘pop out’ rotor access means easier maintenance

- Suited for: oil and gas industry

High Pressure FSXA Series

This series includes heavy duty, high pressure twin-screw pumps designed for applications primarily in the crude oil and power generation markets.

Specifications:

Series Flow Range Maximum Pressure

|

FSXA |

GPM |

L/M |

PSI |

BAR |

|

310FSXA |

25-150 |

95-570 |

1,400 |

97 |

|

360FSXA |

50-350 |

190-1,325 |

1,300 |

90 |

|

655FSXA |

90-630 |

340-2,385 |

1,300 |

90 |

|

1250FSXA |

150-1,200 |

570-4,540 |

1,400 |

97 |

|

2030FSXA |

250-1,900 |

945-7,190 |

1,200 |

83 |

|

2530FSXA |

420-2,300 |

1590-8,700 |

1,400 |

97 |

|

3830FSXA |

600-3,700 |

2270-14,000 |

1,200 |

83 |

Product Design: Horizontal

Other data

Design standard: Manufacturer STD, API 676

Fluids: Fuel Oils, Lubrication Oils, Oils > Crude Oil, Water

Sealing: Single Mechanical seal, Double Mechanical seal

Certification: Class 1 div 2

- Casing and bearing housing Cast steel or stainless steel or iron, with chrome plated bores for added lifetime

- Rotors Standard Material - 4340 steel (ASTM A668 Class M); with optional hardening and plating available

- O-rings Viton (in contact with pumpage), nitrile (in contact with lubricating oil)

- Seal Single component seal at each shaft end

- Flow rate range 200 gpm - 8,200 gpm (45 - 1,860 m3/h)

- Outlet pressure 1,500 psig (103 bar)

- Inlet pressure Up to 500 psi (35 bar)

- Viscosity 0.5 - 100,000 cSt

- Temperature -20 °F - 225 °F

- Speed 1,780 rpms

- Drive Direct only

- Rotation Clockwise facing pump driveshaft

- Mounting Horizontal

- Port Connections Per ANSI B16.5, 300# inlet, 600# discharge

- Accessories Upon request, a temperature and vibration monitor is provided with 1/2” NPT connection

- Timing gears Herringbone, hardened

- Bearings Six bearing design; heavy duty roller bearings

Max. gpm: 8,200.00

Max. lpm: 31,040.38

Max. m³/hr: 1,862.42

Max. bar (dp): 103.42

Max. psi (dp): 1,500.00

Pressure Class (ANSI): 125, 150, 250, 300, 600

Max cSt [mm²/s]: 21,590.10

Max SSU: 100,000.00

Min cSt [mm²/s]: 0.50

Min SSU: 24.00

Max. °C: 107.00

Max. °F: 225.00

Min. °C: -29.00

Min. °F: -20.00