Chameleon Pump Technology

Designed for paint and coating manufacturing

Zenith Pumps for Paints and Coatings allow dependable control of critical coating applications. High accuracy eliminates costly over-application associated with less accurate methods, and the pumps often pay for themselves in savings in one year or less.

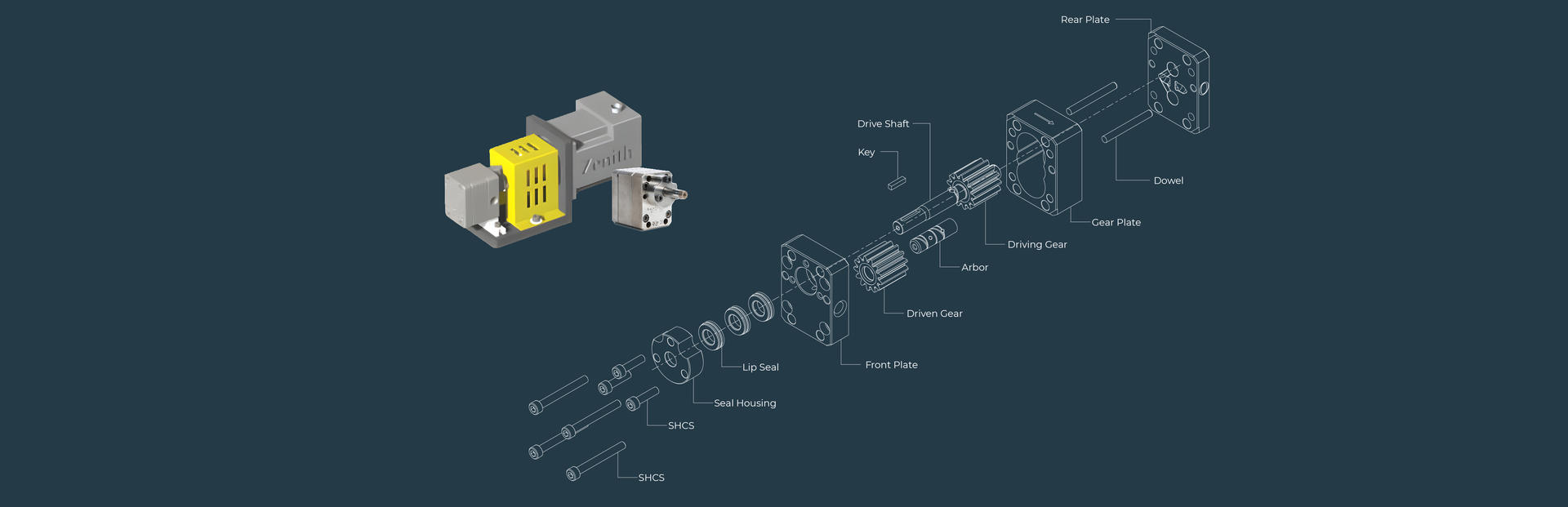

Leak Free

Our leak free triple lip-seal design provides redundant sealing and leak-free performance without the maintenance issues of packings or the complication of face seals.

Compact

2.5" x 1.9" and weight of 2 lb. (3cc) or 2.5 lb. (6cc) - full-size features compressed into a small, lightweight package

Flushable

Change colors in seconds - Chameleon design features allow quick and effective flushing, in-line, resulting in rapid changeover of paint colors and types.

PULSELESS

Rotary spur gears provide smooth, continuous flow without the trouble and expense of check valves, accumulators and complex hydraulic circuitry.

High Pressure

Pressure manufacturing tolerances of +/-.00005" (1.25 micron) allow clearances to be kept to a minimum, and high process pressures to be achieved.

Active Flowmeter

Closed-loop speed control of precise components ensures accurate flow control without adding a secondary flowmeter

Accurate

Stable, repeatable flow control despite process variations due to temperature, viscosity and pressure

Zenith Quality & Support

Certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry.

Zenith

Flushable Paint

Pump Series

Featuring fast, effective, in-process flushing for the challenges of frequent color change or flow stagnation.

Applications

Zenith Pumps for Paints and Coatings are broadly applied to services such as resins, catalysts, colorings, binders, adhesives, coatings, inhibitors, solvent and water-based paints, clear-coats, varnishes and dyes. Zenith Pumps success with paint is because they are designed to provide stable, precise, repeatable flow control, despite variations in temperature, viscosity, and pressure. Zenith Pumps offer quick, effective, in-process flushing for applications requiring frequent color changes or where flow stagnation is a concern.

Rotation: Clockwise and Counter (Contra) Clockwise available

Capacities: 3.0 cc/rev, 6.0 cc/rev

Flow Rate: 30 – 1800 cc/min, 0.03 – 1.8 liters/min

Accuracy: +/- 1% of full range set speed, balanced pressure

Repeatability: +/- 0.1% of setpoint (control dependent)

Temperature Limit: 300°F, 150°C

Recommended Speed Range: 10 – 300 RPM

Inlet Pressure Range: 0 – 300 psi, 0 – 20 bar

Discharge Pressure Range: 0 – 1000 psi, 0 – 69 bar

Viscosity Range: 1 – 100,000 cp

Inlet/Outlet Port Connections: 1/8-27 NPT,1/8 BSPP, or rear porting

Materials of Construction: 400 series stainless steel standard; High-vanadium Stainless and Diamond-like Coatings available.

Seals: 3PTFE™ – Triple Lip seal, with fluorocarbon elastomers