Zenith Metering Systems

WHEN ACCURATE ADDITIVE DELIVERY IS VITAL

Our engineering experts design your metering pump systems for any process or application.

Ensuring the integrity of your dosing process requires the best engineering minds. But cost and overall product appeal are just as important to OEMs in the food and beverage, nutraceutical and personal care product markets. How do you find the systems partner that will take all of that into consideration?

Zenith’s engineering experts design and tailor your metering pump systems to any process application for which you’re responsible. With numerous designs and materials of construction to choose from, it is our standard of service to offer you the most value and lowest total cost of ownership in every solution. We will provide you with the right system for the right price.

| Our Systems Can Accommodate: | |

|---|---|

|

|

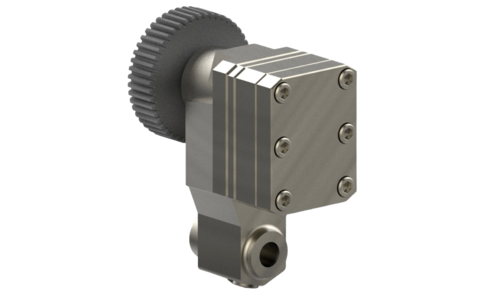

Customizing a Packaged Pump Solution

Delivering engineering and design expertise for solutions that address unique process requirements and save time and money

Sometimes, the standard line of Zenith pumps cannot meet unique process requirements. Zenith engineers and technical experts have been designing and manufacturing custom pumps and systems since 1926 to deliver complete packaged solutions from pumps to supply tanks. Our engineering and design team can work directly with you and your team to build a pumping system that not only meets your specific application parameters but saves time and money.

Some examples of custom designs include:

- Special lubrication features

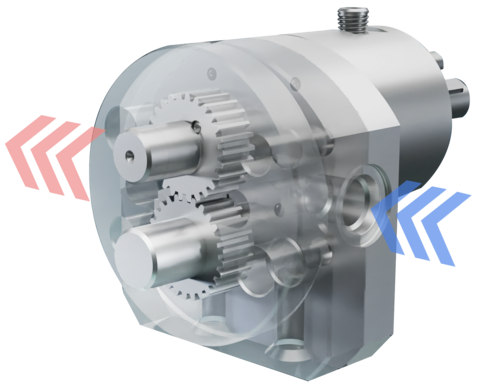

- Pumps with exposed gears for very low inlet pressures

- Special gear designs – to provide more gear tooth strength and lower shaft bearing loads

- Special materials:

- For high temperature

- For corrosion resistance

- For abrasion resistance

- For wear resistance

- For galling resistance

- Specialty coatings

- Special shaft seals

- Internal clearances

- Multiple Stream pumps

- Custom footprints and connections

Decades of experience with customized pumps has enabled us to build and maintain a vast collection of pump designs that were created for specific applications that may be similar or the same as your specific requirements.

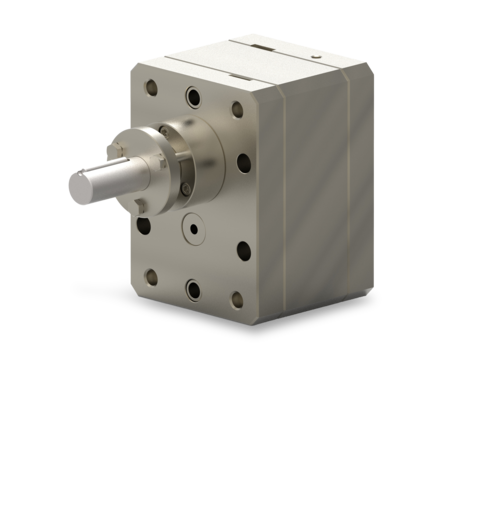

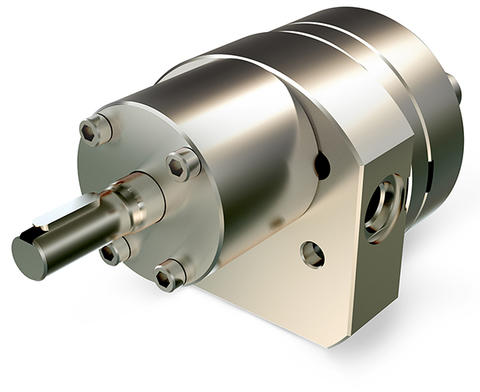

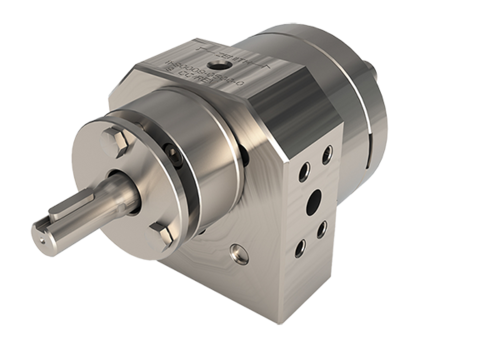

Zenith precision gear metering pumps provide accurate‚ reliable‚ pulse-free metering performance over a wide range of process applications and fluid conditions.

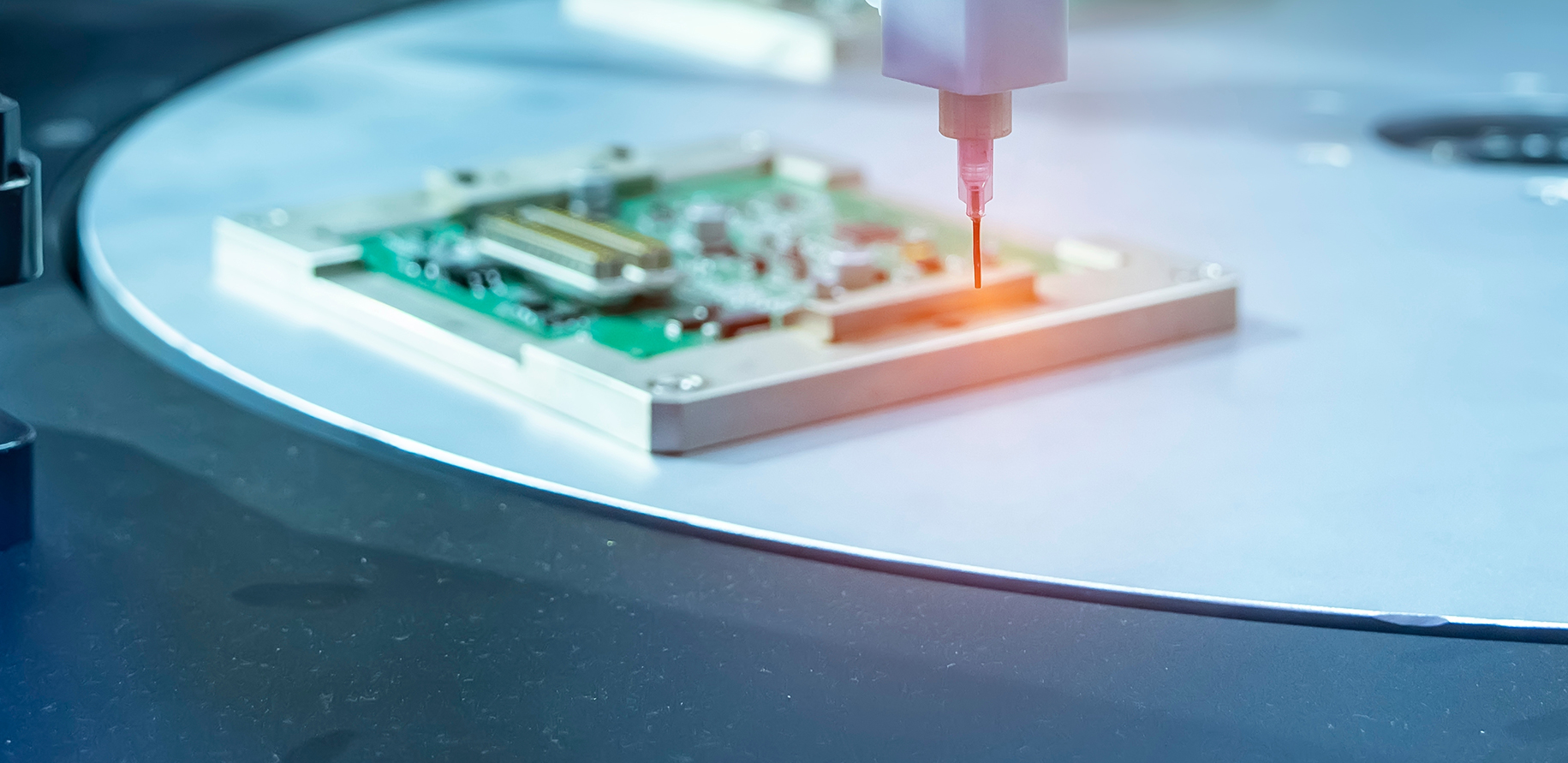

Precision, with consistency, is everything. That’s why we design and tailor your metering pump systems to any process application, including dosing, filling, injection, coating, coloring, flavoring, extruding, spraying and fiber spinning.

The plastics industry relies heavily on precision and efficiency, and CIRCOR’S ZENITH METERING PUMPS are engineered to deliver just that.

Solutions for Adhesives and Sealants

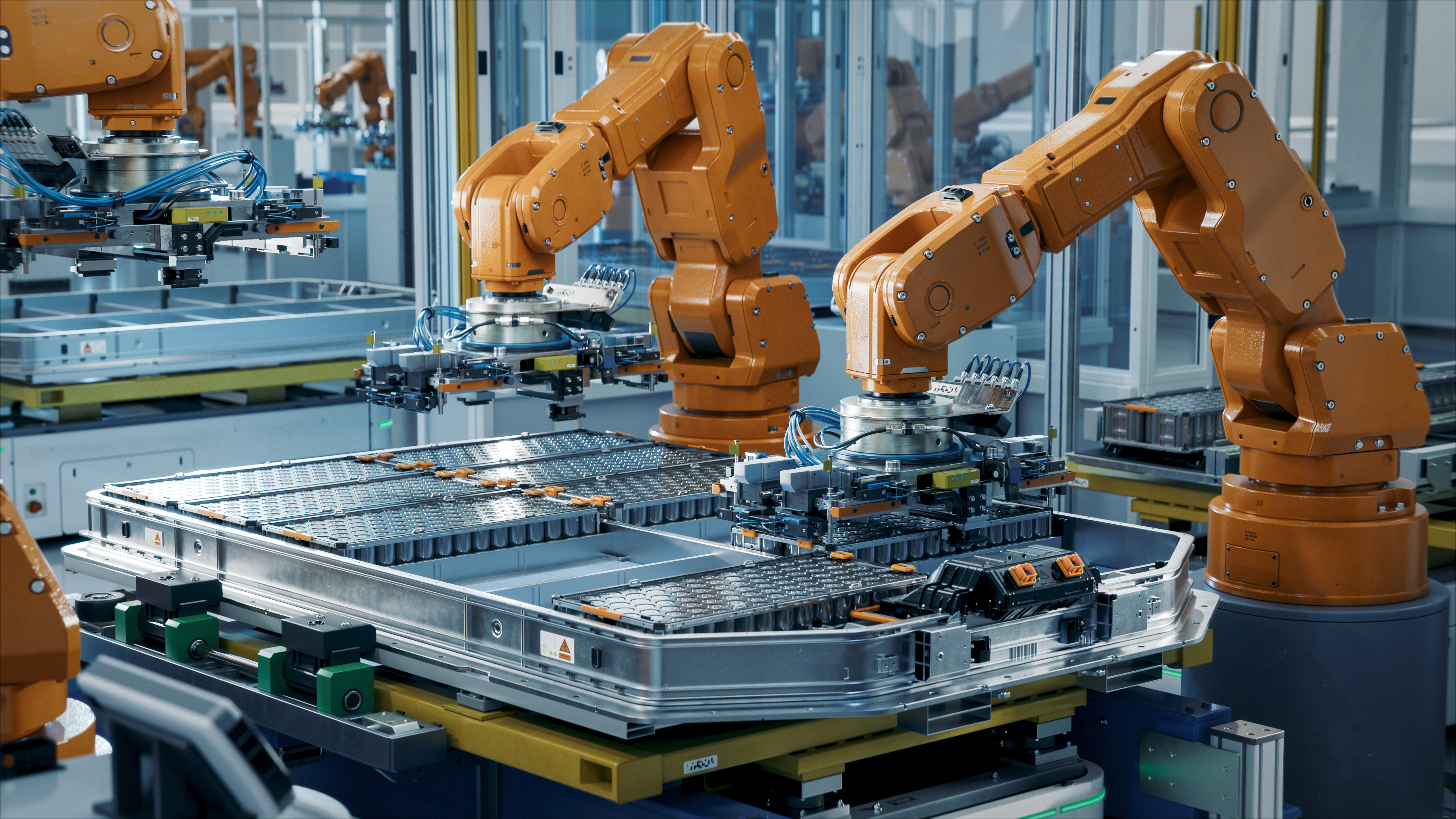

Zenith Pumps provide superior accuracy and flow control for key battery production processes, ensuring consistent quality and efficiency in the fabrication of lithium-ion, solid-state, and other advanced battery technologies.

Our Systems Approach for Additives and Ingredients

Whether you are spraying, blending or injecting your fluid material, repeatability is of paramount importance. Zenith products assure accurate metering over a wide range of applications and process fluid conditions. Add a drive system and incorporate a closedloop speed controller to maintain metering accuracies of +/- 1 percent.

In addition to accurate delivery, close tolerance precision gear metering pumps with only two moving parts are reliable in service and have virtually pulse-free fluid performance. A gear metering pump’s tight internal clearances are as small as 50 millionths of an inch, ensuring a consistent flow rate and high-pressure capabilities where they are needed the most.

- Makeup

- Candy

- Ice cream

- Toothpaste

- Liquid Soap

- Paper Towels

- Trash Bags

- Glue, Coloring

- Flavoring

- Oils

- Lecithin

- Vitamins

- Sprays

- Fragrance

- Colorants

- Fillers

- Antioxidants

- Surfactants

- Emulsifiers

- Preservatives

- Adhesives

- Expensive Trace Ingredients

Pump Equipment Packages Make the Difference

A packaged metering system approach will always offer the most value and overall lowest cost of ownership.

Programmable logic controllers and controllers for speed, pressure and temperature

Modular designs using mobile carts and base mounted assemblies

Accessories such as tanks, mass flow meters, level sensors, mixers and control valves

Test Stands

Custom layouts and system integration conforming to customer satisfaction

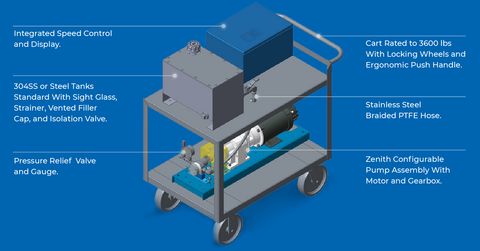

Zenith Modular Systems

All-In-One Solution for Your Precision Pumping Applications

Turnkey Solution

We’ve done the design, sourcing, and integration work for you.

Versatile

Pick only the options you need. Roll it to where you need it, when you need it

Rugged

Heavy-duty cart, tanks, and accessories designed for industrial environments.

Precise

Accurate, repeatable, pulse free Zenith pumps.

Ideal Solutions for:

| Markets | Performance | Applications |

|---|---|---|

| Consumer Goods | Up to 0.5 % accuracy to setpoint | Spray, dispense, blend |

| Industrial & Chemical | Up to 1,200 cc/min or 0.32 gpm | Research and development |

| Life Sciences | Up to 1,000 psi | High mix production |

3-D model Examples of our Total Metering Systems Solutions

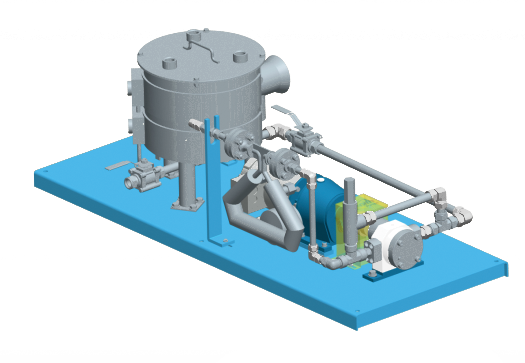

Inline Pump System

-

Heated stainless steel tank

- Level transmitter

- Flow meter

- Pressure transducer

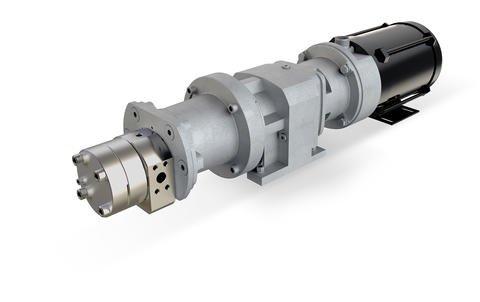

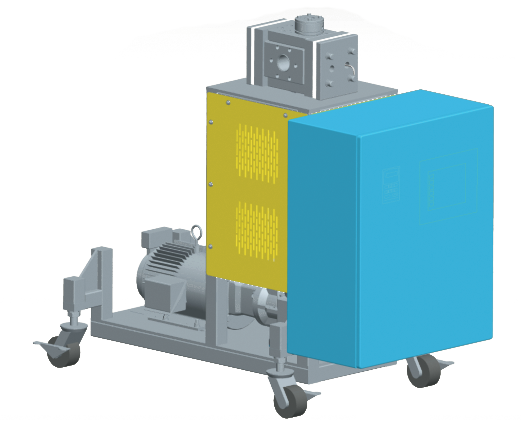

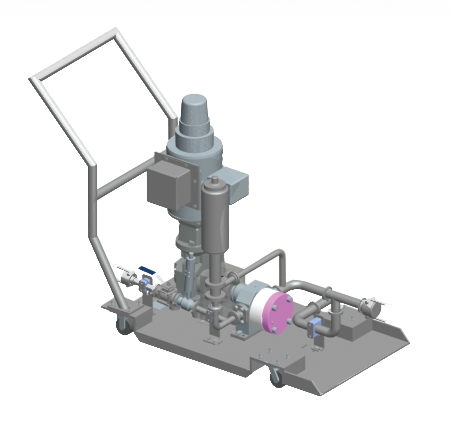

Right-Angle Pump System

- Temperature, pressure and speed alarms

- Pump with cast-in electric heaters

- LCD touch screen and PLC

- Temperature control (two zones)

- Pressure monitor and control

- AC inverter duty motor with 1024 PPR encoder

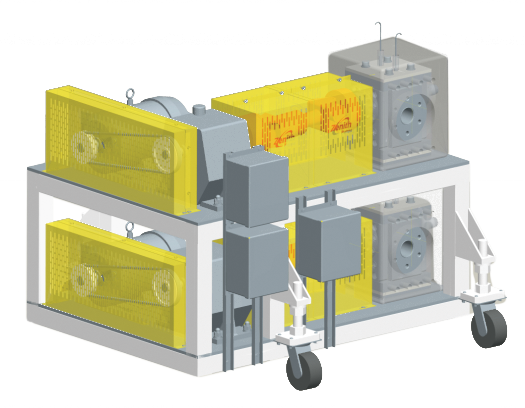

Two-level, Dual Pump System on a Custom Cart

- Swivel casters with height adjustment

- Belt driven, inline reducers

- Electric cartridge heaters for pumps

- AC inverter duty motors

- Electric wiring to low and high voltage junction boxes

- Temperature controller

Right- Pump System

- Stainless steel push cart

- Relief valve

- Isolation valve

- Welded tube assembly

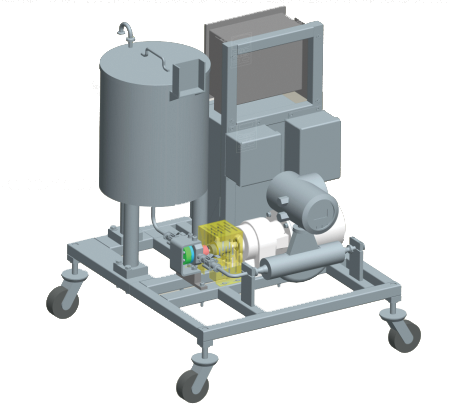

Inline Pump System

- Locking swivel casters with brakes

- Sanitary connections

- Stainless steel tank

- Mixer

- Temperature control (two zones)

- Flow meter

- Feed controller

- Maximized cost reduction

- A wide variety of pumping systems

- Streamlined manufacturability

- Electronics and creative design

- Fast deliveries, minimal lead times

- Application-specific solutions

- Custom piping, custom controls

- Single-source for all components

- Complete and specific manuals and

documentation

- Custom 3-D CAD drawings

Accurate, Reliable, Pulse-Free Additive Delivery is at Hand

Built with quality construction materials vetted through our supplier qualification process, our metering pumps and systems deliver the efficient, repeatable performance you demand, backed by sales and application engineers who are some of the best in the business and who provide ongoing support. Stop worrying about performance variances and higher operating costs from inconsistent and/or pulsating flow. Say goodbye to ruined or off-spec products, with the resulting productivity losses, increased rework and excessive product waste. Contact us today to find out what a Zenith system can do for.