Wastewater

Sewage Transport

Efficient transport of industrial wastewater without harming people and environment

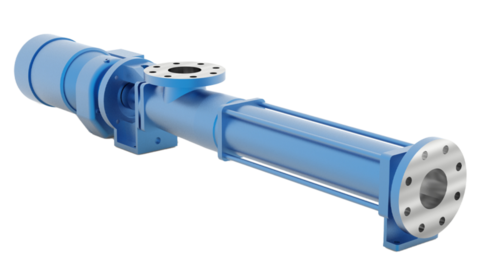

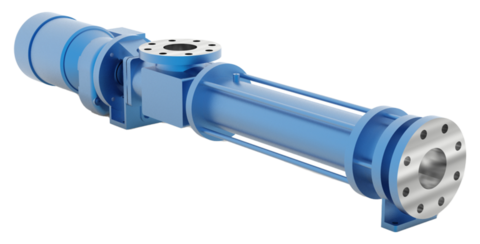

Allweiler Progressing Cavity Pumps achieve flow rates of up to 500 m³/h.

Sewage transport is a critical process that ensures that domestic and industrial wastewater, as well as rainwater, is transported to the wastewater treatment plant (WWTP) efficiently and without harm to people or the environment. This process involves collecting wastewater from various sources, such as industrial plants and municipalities, and transporting it through a complex sewer system.

Sewage Transport Process Explained

Municipal and industrial wastewater is first collected in local reservoirs. These serve as temporary storage tanks that can hold large volumes of wastewater before it is passed on. The collected wastewater is then transported through a network of sewer pipes. This transport phase must be designed efficiently in order to transport the wastewater over long distances and varying topographical conditions to the WWTP. High-performance pumps are required, especially in geographically challenging areas with large differences in elevation. Progressing cavity pumps are particularly effective because they can reliably pump wastewater even against high hydraulic pressures. Their robust design allows them to handle sewage with high solids content without loss of performance or malfunction.

Pump Requirements for Sewage Transport

Efficient and safe sewage transport requires pumps that meet specific criteria. These include the ability to overcome large differences in elevation, a high pressure rating, and the ability to handle varying levels of solids in the wastewater without the risk of clogging. In addition, the pumps must be robust and adaptable to different and demanding environments.

In cases where the solids content of the sewage is particularly high and conventional centrifugal pumps reach their limits, progressing cavity pumps are the preferred choice. These types of pumps are particularly suited to difficult conditions because they can reliably handle high pressures and pump solids efficiently and without clogging. Their exceptional ruggedness and adaptability make them essential for continuous, trouble-free operation in critical sewage pumping applications.

Our Solution for Your Sewage Transport Challenge

Allweiler uses their many years of experience and expertise to develop special pump solutions for sewage transport that are optimally tailored to the requirements and challenges of WWTP operators. Our progressing cavity pumps are particularly in demand for applications involving high solids content and large head differences. These products are exceptionally robust and efficient, making them ideal for demanding wastewater applications.

Sludge & Polymer Pump Quick Selector Tool

Fast. Focused. Technically Reliable.

The Sludge and Polymer Pump Quick Selector is an intuitive tool designed to simplify the preselection of progressing cavity pumps for demanding sludge and polymer applications. By entering a few essential operating parameters, users quickly receive a technically sound pump configuration tailored to their process requirements.

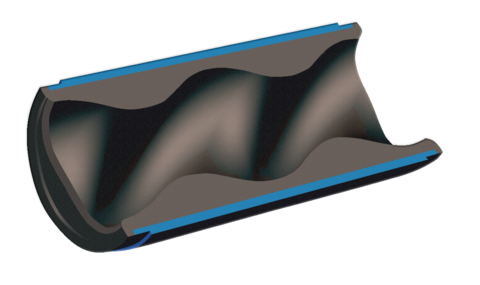

Optimizes all hydraulic characteristics such as flow pattern, power absorption and distribution, and lubrication to ensure long service life and maximum efficiency.

3.800

Max. Discharge Pressure [bar] :6

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :300.000

Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR). Suitable for a wide range of fluids.

1.600

Max. Discharge Pressure [bar] :10

Max. Fluid Temperature [°C] :100

Max. Viscosity [mm²/s] :190.000

Specifically developed for our progressing cavity pumps with a clear focus on cost effectiveness. The compound formulation is the key to how long a stator will maintain its original flow rate.

Targeted dosing of flocculants, especially polymers and ferric chloride, plays a central role in effective sludge treatment in wastewater treatment processes.

Dewatering and preparing sewage sludge for further treatment is a particular challenge for wastewater treatment plant operators.