Wastewater

Transport of Dewatered Sludge

Dewatering and preparing sewage sludge for further treatment

Allweiler hopper pumps can handle dry solid content of up to 45 %.

Dewatering and preparing sewage sludge for further treatment is a particular challenge for wastewater treatment plant (WWTP) operators. After the sludge has been collected in special containers and concentrated by advanced dewatering machines such as centrifuges or screw presses, the hopper pump is a key component in the transition to final drying. Designed for the efficient transport of highly concentrated sludge, this specialized pump plays a central role in the economical and environmentally friendly transport of sludge to the final treatment station, even under the most difficult operating conditions.

Process explained

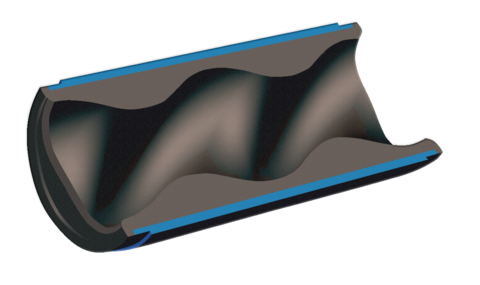

After the sludge has been thickened by the previous treatment steps, it reaches a consistency where conventional progressing cavity pumps reach their limits. This is where the hopper pump comes in. The dewatered sludge is fed into the hopper of this special pump, a process that is carefully controlled to ensure optimum feeding. Inside the hopper, the sludge is homogenized and larger lumps are removed. This is also where the sludge is fed into the rotor-stator cavities of the progressive cavity pump, so that a high filling level is achieved and partial dry running is avoided. This creates the best conditions for trouble-free pump operation.

Pump Requirements

In wastewater treatment, hopper pumps are the product of choice for the efficient transport of sewage sludge. These pumps must be robust and durable to withstand the abrasive and sometimes corrosive nature of the sludge. An important feature is their ability to homogenize sludge that is mixed with flocculants and tends to form lumps. This process facilitates further treatment. Flexibility in handling different sludge consistencies and high energy efficiency are other important features that reduce operating costs and promote environmental protection. Easy maintenance and high reliability minimize downtime and increase system efficiency. By selecting hopper pumps that meet these requirements, WWTP operators can optimize sludge transport and dewatering, resulting in more sustainable and economical wastewater treatment.

Our Solution for Your Challenge

Allweiler offers an innovative solution with a specially designed hopper pump that is ideal for handling highly concentrated sludge.

The large hopper throat, the two intermeshing mixing and conveying screws, as well as the generously dimensioned stuffing chamber ensure trouble-free operation without bridge building and dry running.

The Allweiler RG hopper pump does not require any additional bridge breaker systems, which saves energy costs caused by additional motors.

For WWTP operators, the introduction of this advanced pump technology means a significant optimization of the dewatering and drying process.

Sludge & Polymer Pump Quick Selector Tool

Fast. Focused. Technically Reliable.

The Sludge and Polymer Pump Quick Selector is an intuitive tool designed to simplify the preselection of progressing cavity pumps for demanding sludge and polymer applications. By entering a few essential operating parameters, users quickly receive a technically sound pump configuration tailored to their process requirements.

Specifically developed for our progressing cavity pumps with a clear focus on cost effectiveness. The compound formulation is the key to how long a stator will maintain its original flow rate.

Sewage transport is a critical process that ensures that domestic and industrial wastewater, as well as rainwater, is transported to the wastewater treatment plant efficiently and without harm to people or the environment.

Targeted dosing of flocculants, especially polymers and ferric chloride, plays a central role in effective sludge treatment in wastewater treatment processes.