Wastewater

Sludge Treatment

Efficient dewatering of sludge, thereby reducing its volume and weight

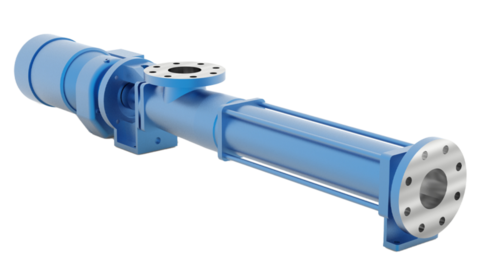

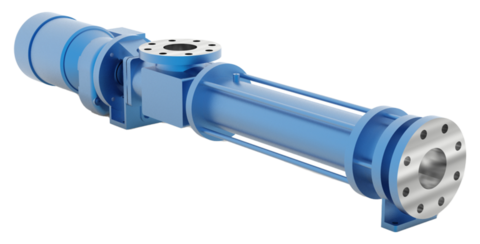

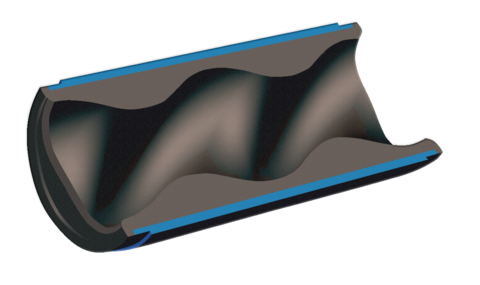

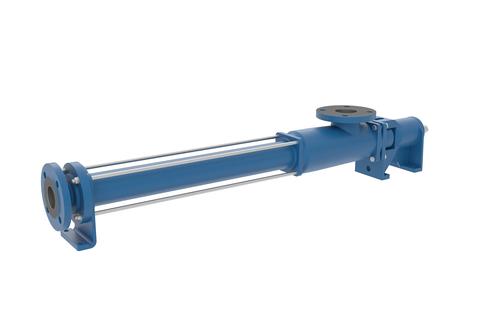

Allweiler Progressing Cavity Pumps with ALLDUR stators achieve up to 500 % longer lifetimes than conventional NBR stators.

An essential element of wastewater treatment is the challenge for wastewater treatment plants (WWTPs) to efficiently dewater the sludge, thereby reducing its volume and weight. This is important not only to make the sludge easier to handle and transport, but also to prepare it for further use in agriculture or as an energy source. This process makes an important contribution to environmental protection, public health and increasing the efficiency of WWTPs by reducing the environmental impact and enabling the recovery of valuable resources.

Sludge Treatment Process Explained

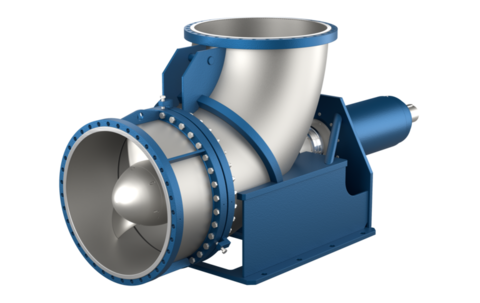

For the operators of WWTPs, the task begins with the careful collection of residual materials generated during wastewater treatment. These include screenings, scraps and grease from grit chambers, floating solids, and sludge. The latter is produced in various concentrations and characteristics at a WWTP and is thickened or dewatered in subsequent steps. This makes transport not only more efficient, but also more cost-effective. Specially designed, robust sludge pumps are responsible for transporting the thickened sludge to further treatment stations or for disposal. These pumps must be designed to withstand the demanding conditions of such a task - including handling abrasive and corrosive materials - and ensure consistent, reliable performance.

Pump Requirements for Sludge Treatment

Selecting pump technologies that meet these specific requirements is critical for WWTP operators. Pump durability and reliability are essential to withstand sludge materials and avoid downtime. Efficiency plays an important role, as energy-saving solutions not only reduce operating costs, but also help to reduce CO2 emissions. The flexibility of the pump technology allows it to adapt to different sludge consistencies and volumes, which is necessary for trouble-free operation. The ease of maintenance reduces repair and maintenance time, increases system uptime and improves overall efficiency. Finally, the environmental compatibility of the technologies ensures compliance with current and future environmental standards and supports the sustainability goals of WWTPs.

Careful selection and implementation of pumps that meet these complex requirements is therefore essential. Not only will this result in more efficient and economical operation, but it will also contribute to environmental protection and regulatory compliance. By meeting these challenges with the right technology, WWTP operators can make a significant contribution to the sustainability and efficiency of wastewater treatment.

Our Solution for Your Sludge Transport Challenge

Allweiler offers a range of specialized pump technologies for sludge treatment in the wastewater industry. Our in-depth understanding of the industry's challenges and our focus on quality ensure that our customers are best prepared to meet the demands of sludge handling.

Our robust and efficient pumps are known for their ability to effectively handle a wide range of sludge consistencies, reducing operating costs and protecting the environment. When you choose Allweiler, you choose quality, performance and reliability in wastewater treatment.

Sludge & Polymer Pump Quick Selector Tool

Fast. Focused. Technically Reliable.

The Sludge and Polymer Pump Quick Selector is an intuitive tool designed to simplify the preselection of progressing cavity pumps for demanding sludge and polymer applications. By entering a few essential operating parameters, users quickly receive a technically sound pump configuration tailored to their process requirements.

Sewage transport is a critical process that ensures that domestic and industrial wastewater, as well as rainwater, is transported to the wastewater treatment plant efficiently and without harm to people or the environment.

Targeted dosing of flocculants, especially polymers and ferric chloride, plays a central role in effective sludge treatment in wastewater treatment processes.