Zenith 1K, 2K, 3K Pump Systems for Foam, Adhesives & Sealants

Multiple Motor & Single Motor Configurations

ACCURATE DELIVERY OF YOUR INGREDIENTS AND ADDITIVES.

Zenith precision gear metering pumps provide accurate‚ reliable‚ pulseless metering performance over a wide range of process applications and fluid conditions. Whether you are spraying, blending or injecting your fluid material, repeatability is of paramount importance. Add a drive system and incorporate a closed loop speed controller to maintain metering accuracies of +/- 1 %.

In addition to accurate delivery, close tolerance precision gear metering pumps with only two moving parts are reliable in service and have virtually pulseless fluid performance. A gear metering pump’s tight internal clearances are as small as 50 millionths of an inch, ensuring a consistent flow rate and high-pressure capabilities where they are needed the most.

Download Flyer

Robust Materials

Robust rotary gear pump materials and design increases MTBR, reducing the risk of production loss due to pump downtime.

Pulseless Flow

Eliminate high pulsation damage to piping and equipment with nearly pulseless flow.

Wear Resistance

Zenith hardened material selections resist wear from abrasives in fluid.

Accurate & Consistent Flow

Reduce wasted fluid costs from inaccurate pump flow in meter/mix applications with our ultra-high pump tolerances.

Quality Service & Support

Our manufacturing plant located in Monroe, NC, USA, offers the highest quality service and support for design, application and engineering.

ISO9001:2015 Certified

We provide the industry's highest quality pumps and parts.

Safety From VOC

Our 9000 Series Pumps are available with optional magnetic drive coupling (sealless pumping) sealing.

|

MANUFACTURING PLANT PUMPING CONCERNS |

|---|

|

|

|

|

|

|

|

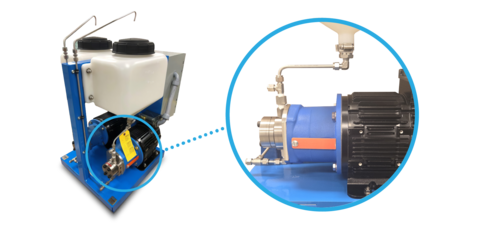

A packaged metering system approach will always offer the most value and overall lowest cost of ownership.

We provide:

- Programmable logic controllers and controllers for speed, pressure and temperature

- Modular designs using mobile carts and base mounted assemblies

- Accessories such as tanks, mass flow meters, level sensors, mixers and control valves

- Custom layouts and system integration conforming to customer satisfaction

- Test stands

Built with quality construction materials vetted through our supplier qualification process, our metering pumps and systems deliver the efficient, repeatable performance you demand, backed by sales and application engineers who are some of the best in the business and who provide ongoing support. Stop worrying about performance variances and higher operating costs from inconsistent and/or pulsating flow. Say goodbye to ruined or off-spec products, with the resulting productivity losses, increased rework and excessive product waste.

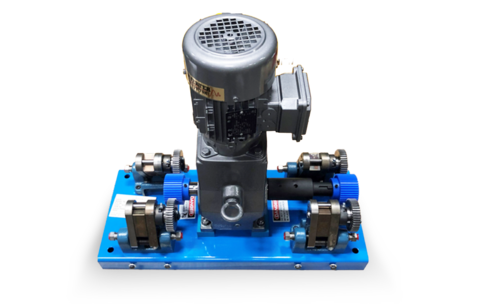

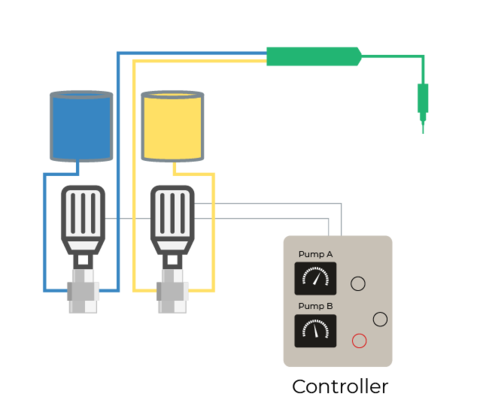

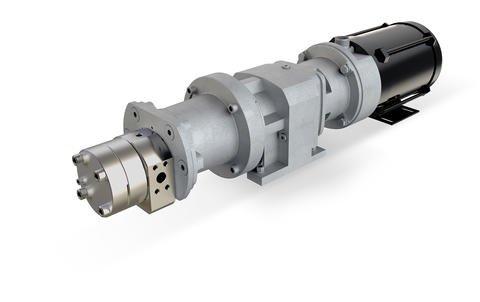

SINGLE MOTOR WITH MULTIPLE PUMPS

The Zenith B Series pumps

The Zenith B Series pumps are broadly applied to metering services such as colorings, catalysts, resins, flavorings, perfumes, vitamins, oils, adhesives, coatings, paints/varnishes, polymers, lubricants, dyes, defoamers, pharmaceuticals, urethanes, fuels and viscose.

4K Pump System with Single AC Motor

3K Pump System with Single

AC motor (up to 8K max)

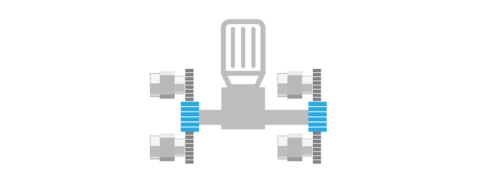

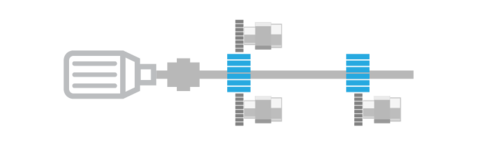

2K PUMP SYSTEM WITH SINGLE SERVO MOTOR

A single motor 2K system allows for the use of multiple pumps with one motor.

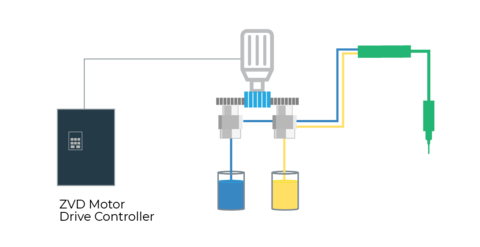

Zenith B Series Pumps with ZVD Drive Controllers.

Decades of experience in manufacturing 1K, 2K and 3K B Series Systems.

CONSISTENT PERFORMANCE STARTS WITH CONSISTENT COMPONENTS.

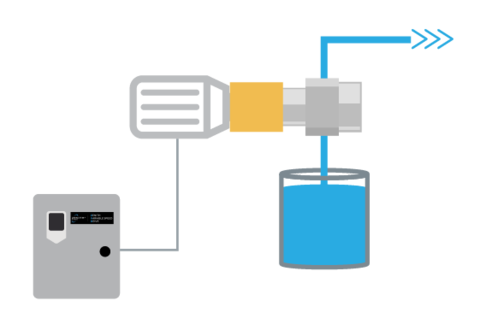

Zenith Variable Speed Drive can be added with the Zenith pumps for additional control.

You want to reduce expensive waste and material costs associated with over & under dispensing. That’s why you need repeatable and accurate shot sizes where precise amounts of fluid must be metered.

The 9000-Series Dispensing System is ideal for even your most critical shot dispensing applications. The system’s unique design features combine Zenith’s state-of-the-art 9000-series metering pumps with the smart controller, resulting in unmatched performance in your fluid dispensing processes.

FINDING A SYSTEM THAT ALIGNS WITH YOUR SPECIFICATIONS IS VITAL.

Zenith Series 9000 Pumps with Controller.

Configurations can be customized to fit your applications.

Examples of components available:

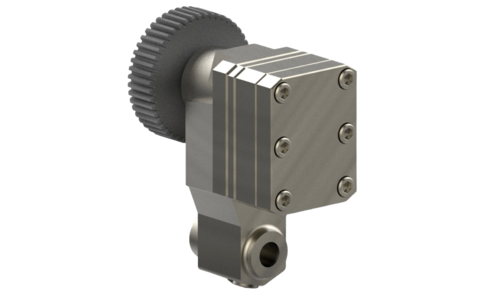

- Magnetic Coupling (Magdrive)

- Controllers

- Servo Motors

- Encoders

- Flow Meters

- Tanks

Works with Servo Motors

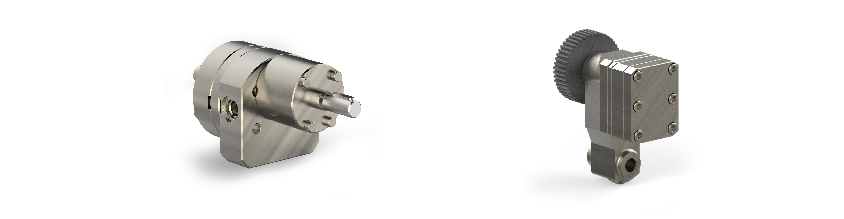

Pairing a magnetic coupling (magdrive) with a Zenith pump eliminates shaft seal leakage.

Zenith's Precision Gear Metering Pumps with single motor, multi motor configurations.

Our 1K, 2K, 3K dispensing/dosing systems feature components engineered to the highest standards. Whether you’re spraying, blending or injecting, you’ll find a system that will meet your needs and budget while delivering superior pulse-free accuracy.

Our systems can accommodate:

- Flows as low as 0.18 cm3/min (0.00005 gpm)

- Pressures up to 10,000 psi

- Viscosities up to 2 million centipoise

- Temperatures from -40 °F to 950 °F

- The design is explosion-proof and seal-less

Our solution can accommodate whatever you are SPRAYING, BLENDING OR INJECTING including: Colors, Flavoring Oils, Lecithin, Vitamin, Fragrances, Fillers, Antioxidants, Surfactants, Emulsifiers, Preservatives, Adhesives, and Expensive Trace Ingredients.

The Zenith metering pump delivers remarkably accurate consistency but installed in a system it wasn’t designed for may adversely affect its performance. With Zenith systems, you can be sure your pump is always operating at the highest level.

MFG in Monroe NC USA

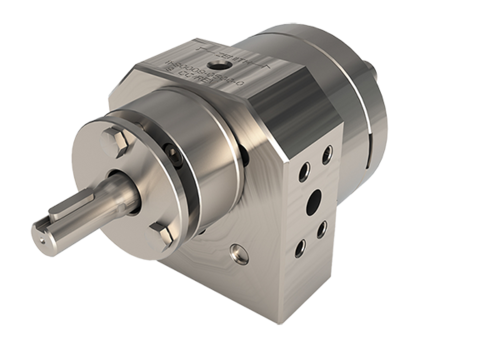

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500

MFG in Monroe, NC USA

The 9000MD eliminates shaft leakage of hazardous fluids, increases plant safety, and reduces VOC emissions.

No leak

Corrosion resistant :titanium stabilized

MFG in Monroe, NC USA

For chemical and polymer fluid metering applications. B-Series pumps have an “outer drive gear” design that allows pumps to be driven by a common pinion gear or multiple pinion gears on a line shaft.

0.16 - 2.92

Max. Flow Rate [GPH] :8.3

Max. Fluid Temperature [°F] :300

Max. Viscosity [CP] :100,000

MFG in Monroe, NC USA

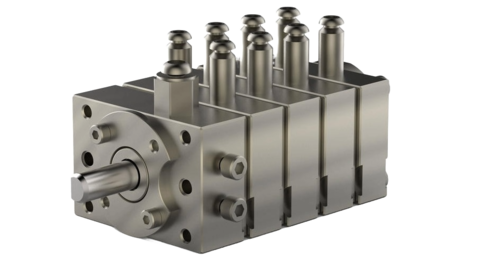

For applications requiring precise multi-stream metering of low viscosity fluids. Commonly used to meter spin finish solutions onto synthetic fiber threadlines.

0.03-1.2

Max. Flow Rate [cc/min] :120

Max. Fluid Temperature [°F] :212

Max. Diff. Pressure [PSI] :100

MFG in Monroe, NC USA

For polymer fluid applications at high temperatures, pressures and viscosities as well as for abrasive fluids.

24,000

Max. Pressure [psi] :4,000

Max. Fluid Temperature [°F] :950

Shaft Seal :Graphoil Packing Seal or Universal Coupling Seal

Solutions for Adhesives and Sealants

Want to find out what a Zenith system can do for you? Fill out the form below and a representative will be in touch.

The plastics industry relies heavily on precision and efficiency, and CIRCOR’S ZENITH METERING PUMPS are engineered to deliver just that.

IMO and ALLWEILER: Floors Above the Competition