Background

What's the story about?

A National Oil Company (NOC) in Africa planned a massive new inlet separation and boosting facility in a mature natural gas field. The plant’s function is to take fluids from the existing gathering system and boost their pressure at the inlet of the existing gas and liquid processing facilities. This infrastructure compresses gas for

commercial sale.

CHALLENGE

What should be achieved?

The EPC initially considered a centrifugal pump for the design of the closed drain drum pump, but struggled to find a solution that could handle very low suction pressure requirements together with a multiple-viscosity process flow. Considering this, there was a clear need to optimize the pump selection, combined with the

fact that it was a constant flow application, and the fluids were flammable and corrosive.

SOLUTION

What's the solution?

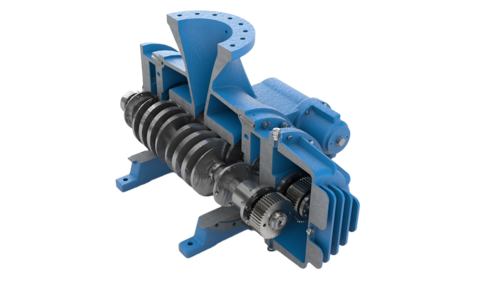

Working with a vendor that had in-depth knowledge and experience in complying with the specifications of the NOC customer was imperative. Identifying CIRCOR as that partner, the EPC worked closely with CIRCOR’s Sales & Applications Engineering teams to develop the pump specification. As a result CIRCOR recommended a progressing cavity (PC) positive displacement pump per API 676 for this application, with double mechanical seals according to API plan 53B for the utmost in safety and reliability.