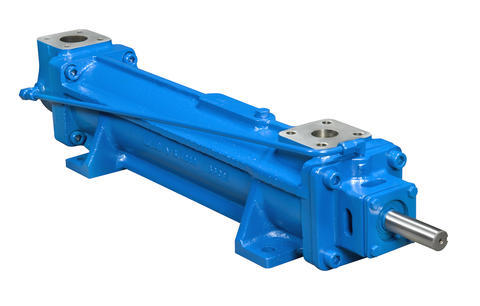

IMO LB6D 3-Screw Pumps

W O R K H O R S E O F T H E O I L F I E L D

IMO 3-screw technology is installed in hundreds of high-pressure pipeline applications around the world. Beyond their substantial functional excellence, the pumps’ simple design provides maintenance advantages that further enhance their value in critical applications. If you’re in the market for increased uptime, decreased maintenance costs and extended service life, why not give us a try?

A Lease Automatic Custody Transfer (LACT) skid is only as good as its component parts. Every part of that skid should be engineered for two outcomes:

- Maximum functional performance and reliability

- Minimum operating expense

Despite challenging crude oil viscosities and oil contaminants prevalent in harsh field conditions, LACT system builders and users have found a booster pump they can rely on.

Benefits

LACT Boosting Solutions That Work For You

High-pressure boost advantages:

Our 3-screw pump technology boosts oil pressure more efficiently than competitive external gear pump technology. Reduced airborne and fluidborne noise is also an attribute of the IMO rotary, 3-screw technology.

Less downtime: Our 3-screw rotor set operates on fluid film with no metal to metal contact. The oil is contained within protective enclosures as it passes through the pump. As a result, costly maintenance intervals experienced from wearing, external gear pump technology is a worry of the past

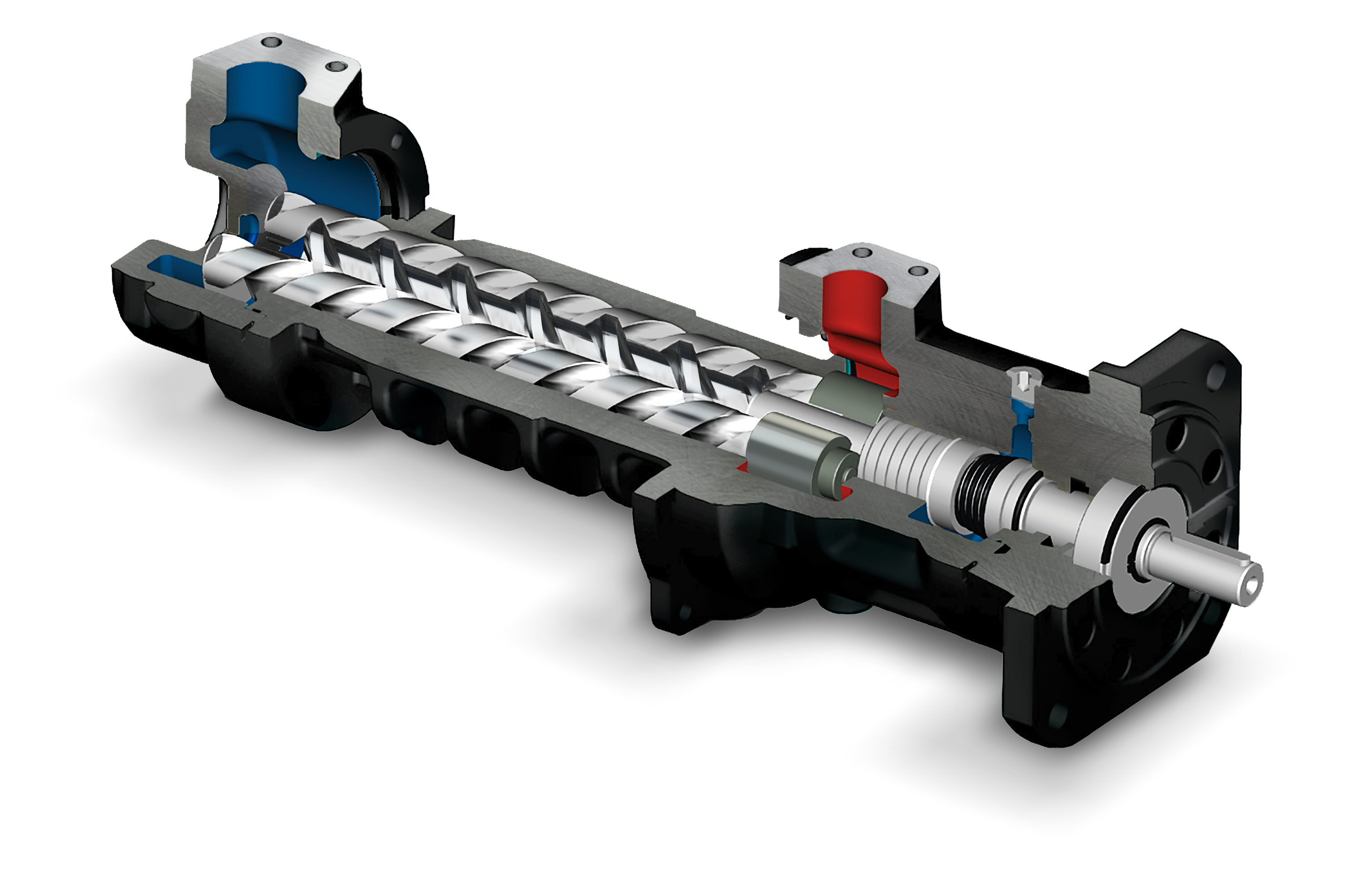

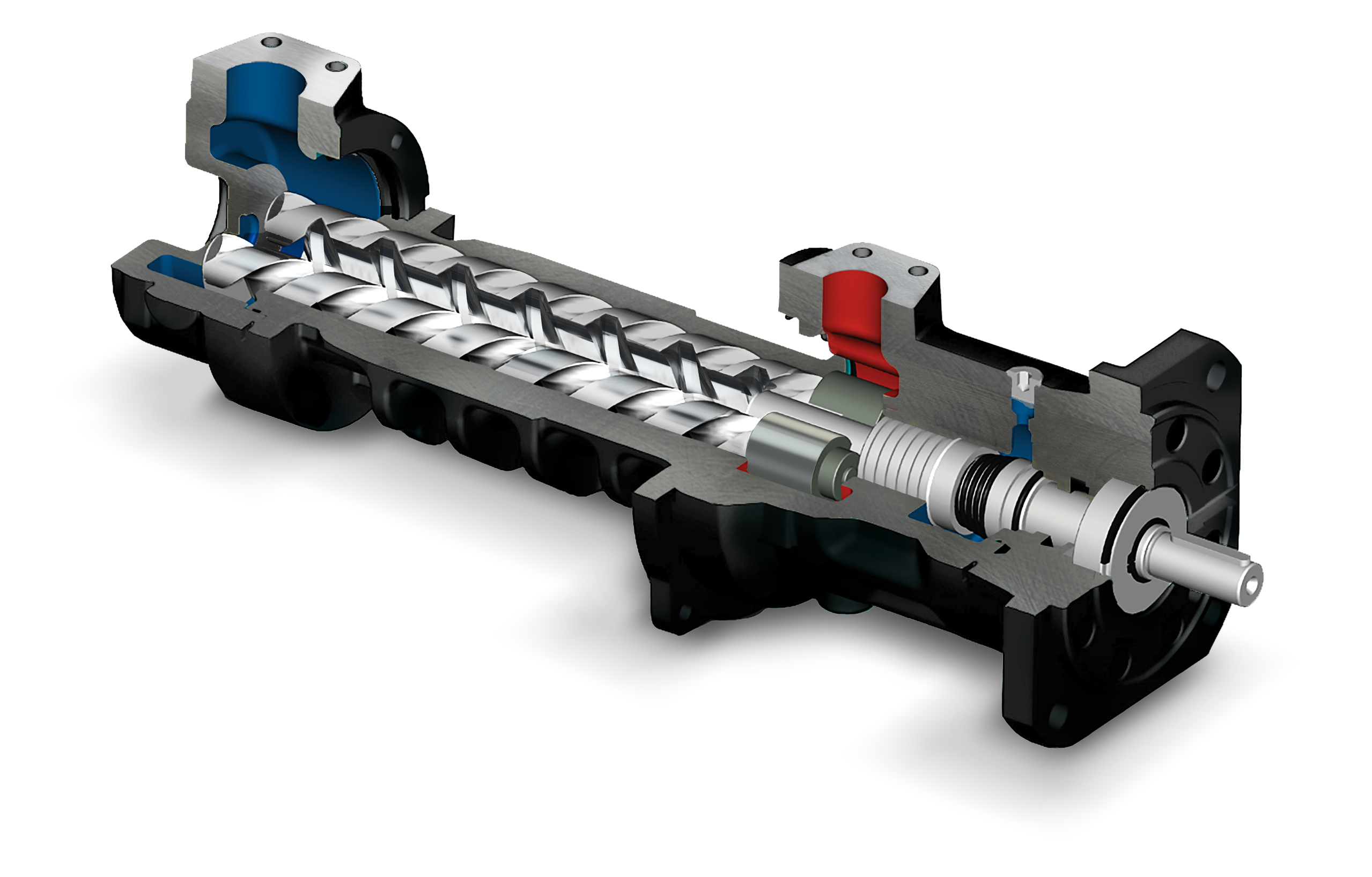

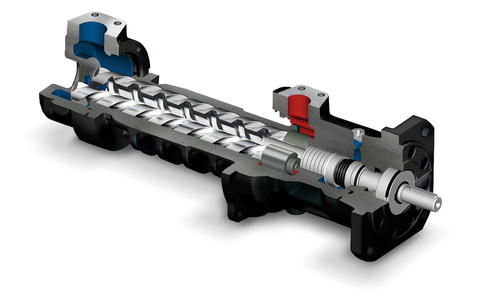

Thoughtful engineering: Key features of the IMO LB6D Series 3-screw pump include a rotor housing with a tri-bore surface hardness similar to that of ceramic, a gas nitride/metal vapor hardened rotor set and silicon carbide mechanical seal faces. This combination of materials and treatments ensure maximum wear resistance.

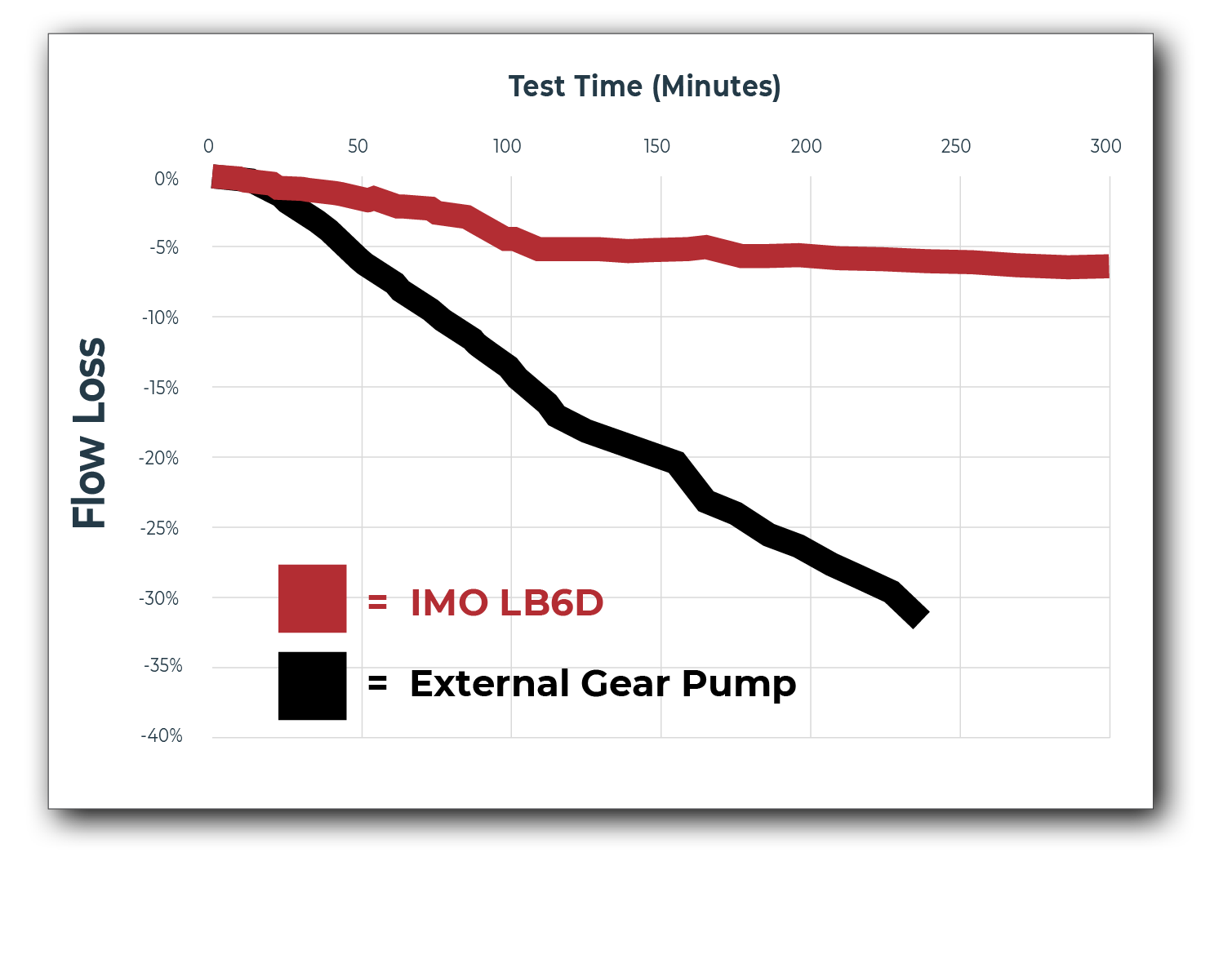

Reduced capital cost: IMO LB6D Series' wear resistance and extended service life has been shown to outperform gear pump technology products by a factor of five.

The results of a four hour accelerated wear test on low viscosity, low lubricity petroleum based fluid with 0.5% hard particle contaminant in a simulated LACT boost installation revealed flow loss nearly five times lower with the LB6D Series than with an external gear pump alternative. The competitive gear pump lost 32% of its flow over the test period compared to the IMO LB6D losing only 6%. In fact, the flow loss of the IMO pump stabilized within this period of time.

Accelerated Wear Test: Flow Loss Vs Time

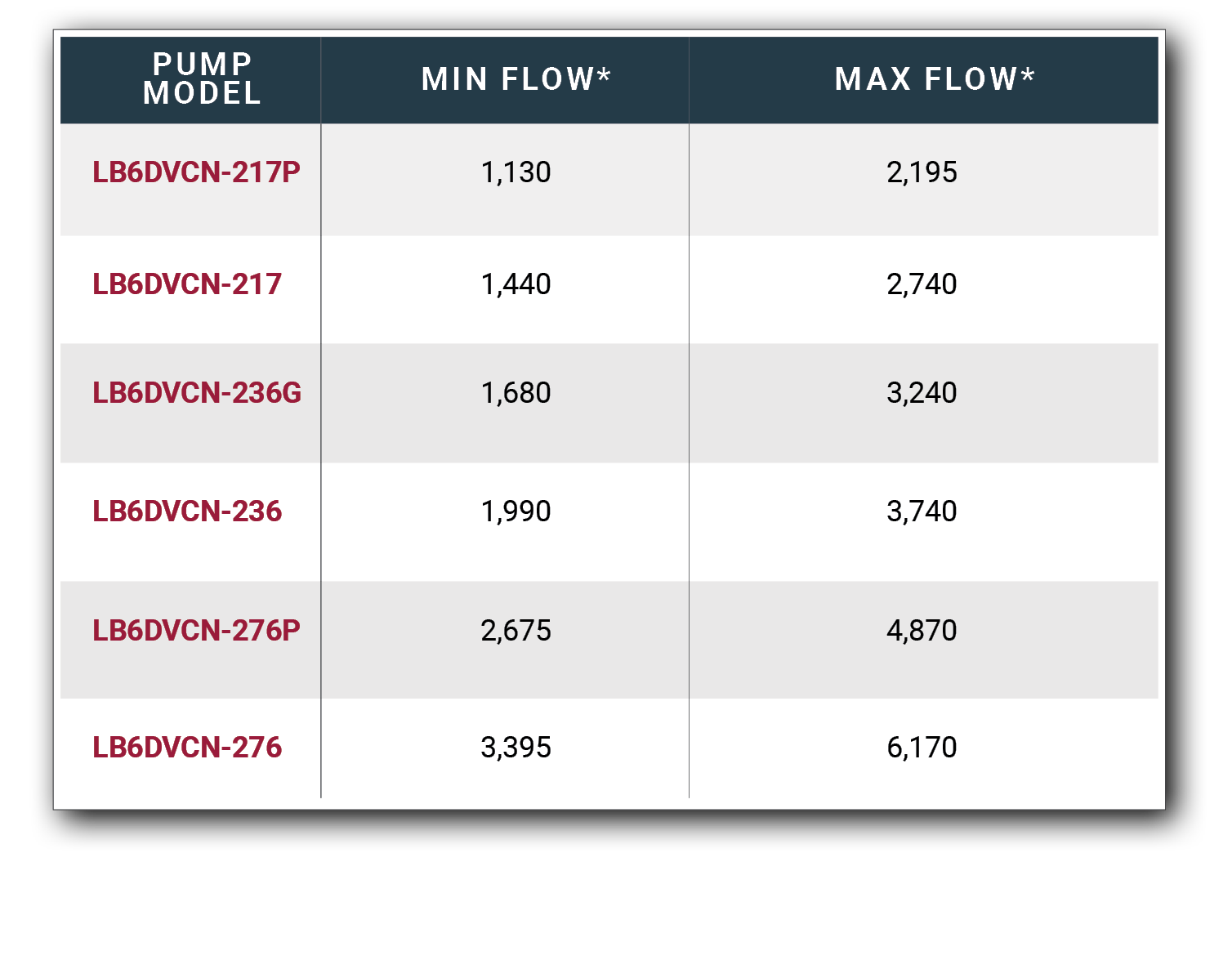

Typical Performance by Rotor Size

IMO LB6D

The World's Most Trusted

Three-Screw Pump

IMO is one of the leading three-screw pump technology brand in the pump industry today. You get all the advantages that matter most to you: longer life, lower pressure ripple, lower contamination sensitivity and maximum energy savings, which results in the highest Total Savings of Ownership across the entire life cycle of your pumping equipment solution.

Made in Germany

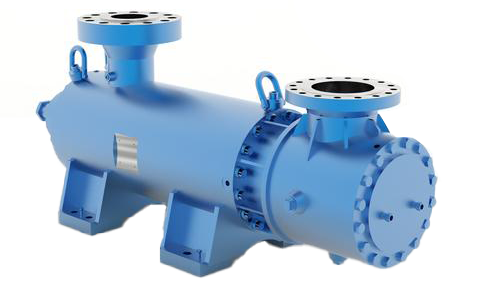

IMO LB6D series pump is used in high-pressure pipeline applications such as Lease Automatic Custody Transfer (LACT).

180

Max. Fluid Viscosity [°F] :176

Max. Inlet Pressure [PSIG] :100

Max. Viscosity [cSt] :760

MFG in Monroe, NC USA

IMO 8L series pumps are designed for pipeline transport in medium to high pressure service on crude oils, fuel oils and other petroleum products.

2,000

Max. Flow Rate [GPM] :2,900

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :225

MFG in Monroe, NC USA

Series 12D Imo pumps are intended for relatively high pressure service on petroleum or similar viscosity liquids.

2,200

Max. Flow Rate [GPM] :400

Max. Viscosity [mm²/s] :5,400

Max. Fluid Temperature [°F] :225

Key Product Features

Improve the Profitability of Your Lease-Gathering Operations

Low Vibration / low noise

Lowering Vibration Contributes to Longer Pump Life

Pump model LB6DVCN-275 operating at 1000psiG. The coin balanced on the pump indicates vibration free operation of the pump. This is inherent of the three screw pump design. As a result, internal and external components are exposed to lower stress which results in longer life. An additional feature of the three screw design is low airborne noise levels. In many cases, the fan on the electric motor will generate more noise than the pump, even at high system pressure.