CIRCOR Highlights Pump Solutions for Road Grade Asphalt Binder Processing and Transfer

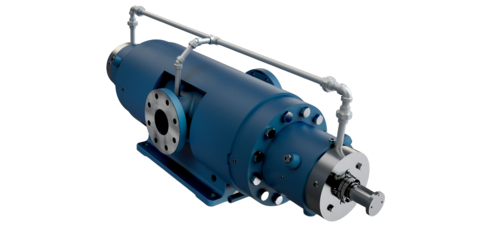

CIRCOR International, Inc., a leading manufacturer and marketer of differentiated technology products and sub-systems, highlights their IMO brand rotary screw pumps for processing and transferring asphaltenes and bitumen in a variety of applications.

With decades of experience, CIRCOR has developed hydraulic balanced pumping technology that simplifies the most complex hydrocarbon processing and transfer tasks.

IMO pumps are designed for a range of applications, from asphalt processing and heated storage to railcar, barge, and ship loading and unloading, as well as refinery residuum transfer and storage.

MFG in Monroe, NC USA

This series pump is found in tank farm services, loading and unloading terminals, power plants and asphalt process and transfer.

500

Max. Flow Rate [GPM] :3,300

Max. Viscosity [mm²/s] :43,200

Max. Fluid Temperature [°F] :500

MFG in Columbia, KY USA

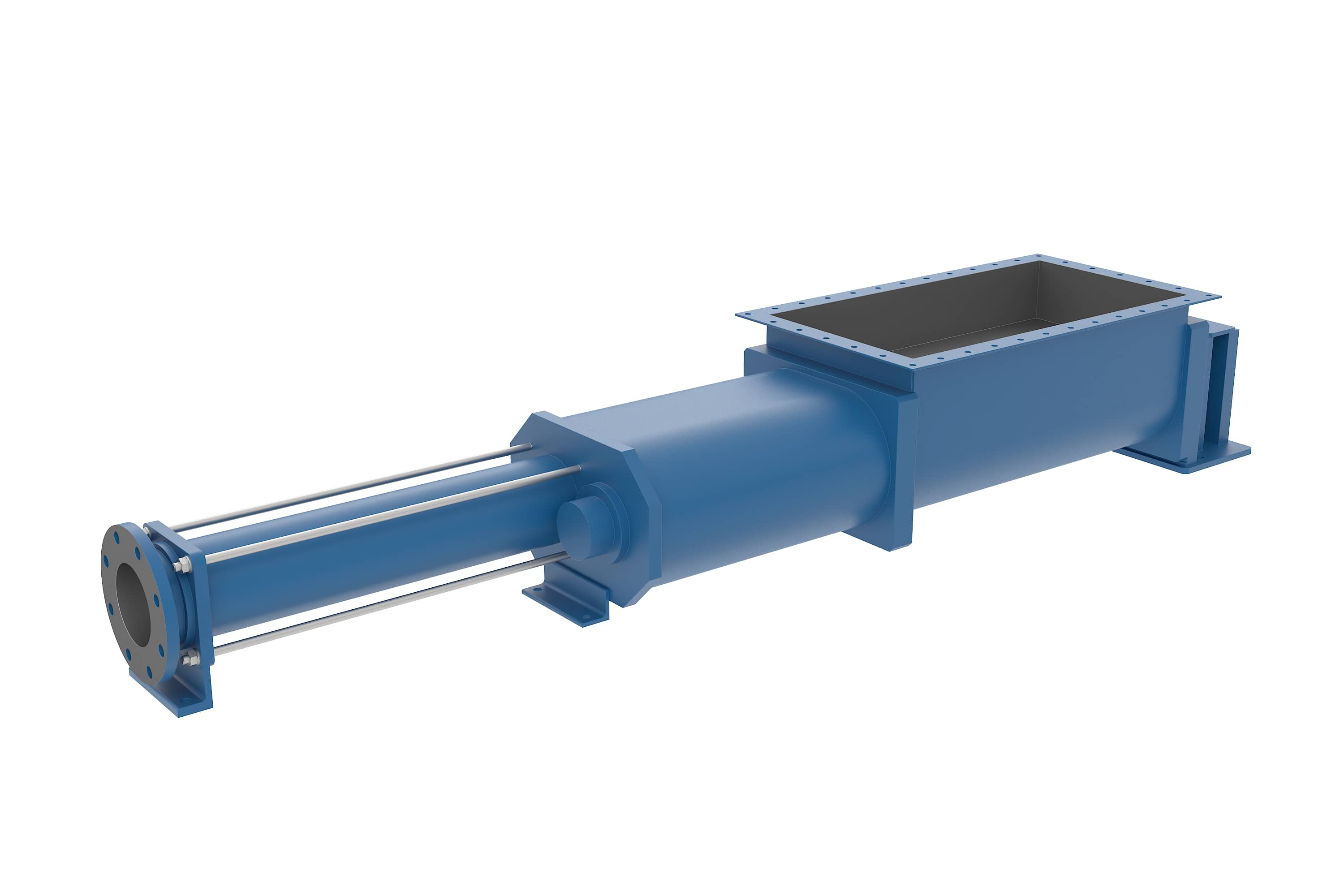

The 413IC series pump is designed for vertical, deep well submerged operation for unloading barges, small tankers or tanks.

150

Max. Viscosity [SSU] :20,000

Max. Fluid Temperature [°F] :300

Max. Speed [RPM] :1,500

MFG in Monroe, NC USA

Series 324A is a double suction design providing relatively high flow rates in a compact pump. These are commonly used for machinery lubrication, fuel oil transfer and burner services and for asphalt and vacuum tower bottoms processing and transfer.

43,200

Max. Flow Rate [GPM] :900

Max. Diff Pressure [PSI] :500

Max. Speed [RPM] :1,800

Max. Capacity [GPM] :900

The IMO Series Jacketed C324A pumps have a double suction design, essentially making it two pumps operating in parallel. This means the pumps are very compact for their flow range. C324A pumps are especially suitable for higher temperature operation, including the transfer of asphalts, vacuum tower bottoms, and more, as there are no antifriction bearings requiring separate cooling. In addition, this series is capable of relatively high speeds making it ideal for steam turbine drive where high speeds improves the efficiency of both the driver and the pump.

For highly viscous fluid at higher flow applications, the IMO Series Jacketed 323F pumps features a rugged design that delivers high performance and reliability. These pumps have been widely utilized in refineries, chemical and petrochemical plants, lubricating systems, and high flow pump boosting stations and can pump polymers, chemicals, glycols, vegetable, oils, paraffins, molasses, grease, paint, asphalt and other highly viscous and/or shear sensitive type fluids in pipelines and process systems.

Designed for vertical, deep well submerged operations, the IMO Series 413IC Deepwell Pump is ideal for unloading asphalt barges, small tankers, or tanks, The pump discharge is axial along the shaft. The design incorporates a third idler rotor which suppresses vibration and noise when the pump is lightly cavitated.

All of these three-screw pump solutions from IMO feature excellent suction lift, long service life, low horsepower consumption, and high contamination tolerance. These benefits mean less downtime, lower energy costs, and lower total pump life cycle costs for the user.

To learn more about IMO three-screw rotary pumps, visit: https://www.circor.com/hydrocarbons-processing-transfer-solutions

About CIRCOR International, Inc.

CIRCOR International, Inc. designs, manufactures and markets differentiated flow control products and sub-systems for Aerospace & Defense and Industrial customers. The Company has a diversified product portfolio of recognized, market-leading brands (Allweiler®, Houttuin™, Imo®, Hale Hamilton, Aerodyne Controls, RTK®, Schroedahl®, Tushaco®, Warren® and Zenith®) that fulfill its customers’ mission critical needs. For more information, visit the company’s website at www.circor.com.

Innovative Screw and Hopper Design Optimizes Pumping Performance for Demanding Applications

Seamlessly Retrofit Marine Pumps for Biofuel Compliance and Carbon Reduction

Revolutionizing Filtration Workflow with Zenith Metering Systems

Streamlining paint and coatings applications with precision and rapid adaptability