CIRCOR Highlights Zenith Pumps for Filtration Manufacturing Applications

CIRCOR International, Inc., a leading manufacturer and marketer of differentiated technology products and sub-systems, highlights its Zenith Pumps tailored specifically for filtration manufacturing applications. With an unwavering commitment to accuracy, reliability, and efficiency, Zenith Pumps are poised to transform the landscape of filter production.

Zenith features a diverse range of pump series, including Series B, Series 9000, Series 9000MD, Spin Finish, and H Series, each meticulously designed to meet the unique demands of filtration manufacturing applications. This includes gluing pleats, metal caps gluing, PU injection, filter gluing inside & out, hollow fiber, and many more.

Zenith’s pump solutions ensure seamless integration and impeccable results in every stage of the filtration process. With their robust design and ability to handle abrasive fluids, additives, adhesives, sealants, polyurethane, and multi-component blending, these pumps are built to deliver outstanding performance.

Zenith Metering Pumps offer a seal-less design, ensuring heightened reliability and reduced maintenance costs, while providing unparalleled accuracy and precision for consistently excellent results. Their capability to handle high viscosity and temperature fluids adds to their versatility and efficiency. Proudly manufactured in the USA, Zenith Metering Pumps guarantee top-notch quality and comprehensive support, making them the ideal choice for demanding filtration manufacturing applications. No one has more experience or material options for dispensing sealants and adhesives than CIRCOR.

Upgrade the filtration process with Zenith Precision Gear Pumps, offering a seamless production experience. These cutting-edge metering systems ensure precision and efficiency at every stage. Whether it's adhesives, sealants, potting compounds, or sealing foams, Zenith's technology guarantees exact metering, thorough mixing, and flawless application, resulting in impeccable results that meet the highest standards of quality and performance.

For more information, visit: https://pumps.circor.com/filtration-applications

About CIRCOR International, Inc.

CIRCOR International, Inc. designs, manufactures and markets differentiated flow control products and sub-systems for Aerospace & Defense and Industrial customers. The Company has a diversified product portfolio of recognized, market-leading brands (Allweiler®, Houttuin™, Imo®, Hale Hamilton, Aerodyne Controls, RTK®, Schroedahl®, Tushaco®, Warren® and Zenith®) that fulfill its customers’ mission critical needs. For more information, visit the company’s website at www.circor.com.

MFG in Monroe, NC USA

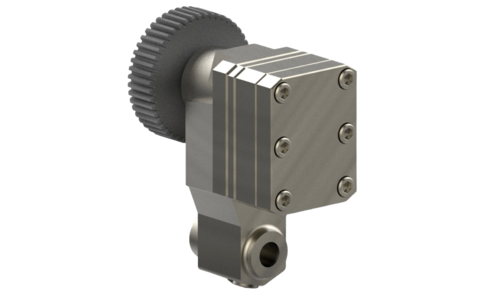

For chemical and polymer fluid metering applications. B-Series pumps have an “outer drive gear” design that allows pumps to be driven by a common pinion gear or multiple pinion gears on a line shaft.

0.16 - 2.92

Max. Flow Rate [GPH] :8.3

Max. Fluid Temperature [°F] :300

Max. Viscosity [CP] :100,000

MFG in Monroe NC USA

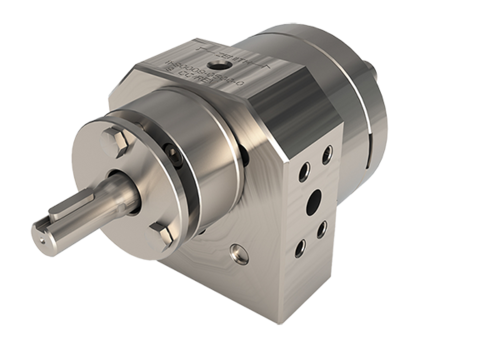

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500

MFG in Monroe, NC USA

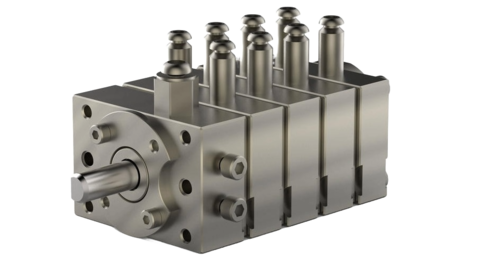

For polymer fluid applications at high temperatures, pressures and viscosities as well as for abrasive fluids.

24,000

Max. Pressure [psi] :4,000

Max. Fluid Temperature [°F] :950

Shaft Seal :Graphoil Packing Seal or Universal Coupling Seal

MFG in Monroe, NC USA

For applications requiring precise multi-stream metering of low viscosity fluids. Commonly used to meter spin finish solutions onto synthetic fiber threadlines.

0.03-1.2

Max. Flow Rate [cc/min] :120

Max. Fluid Temperature [°F] :212

Max. Diff. Pressure [PSI] :100

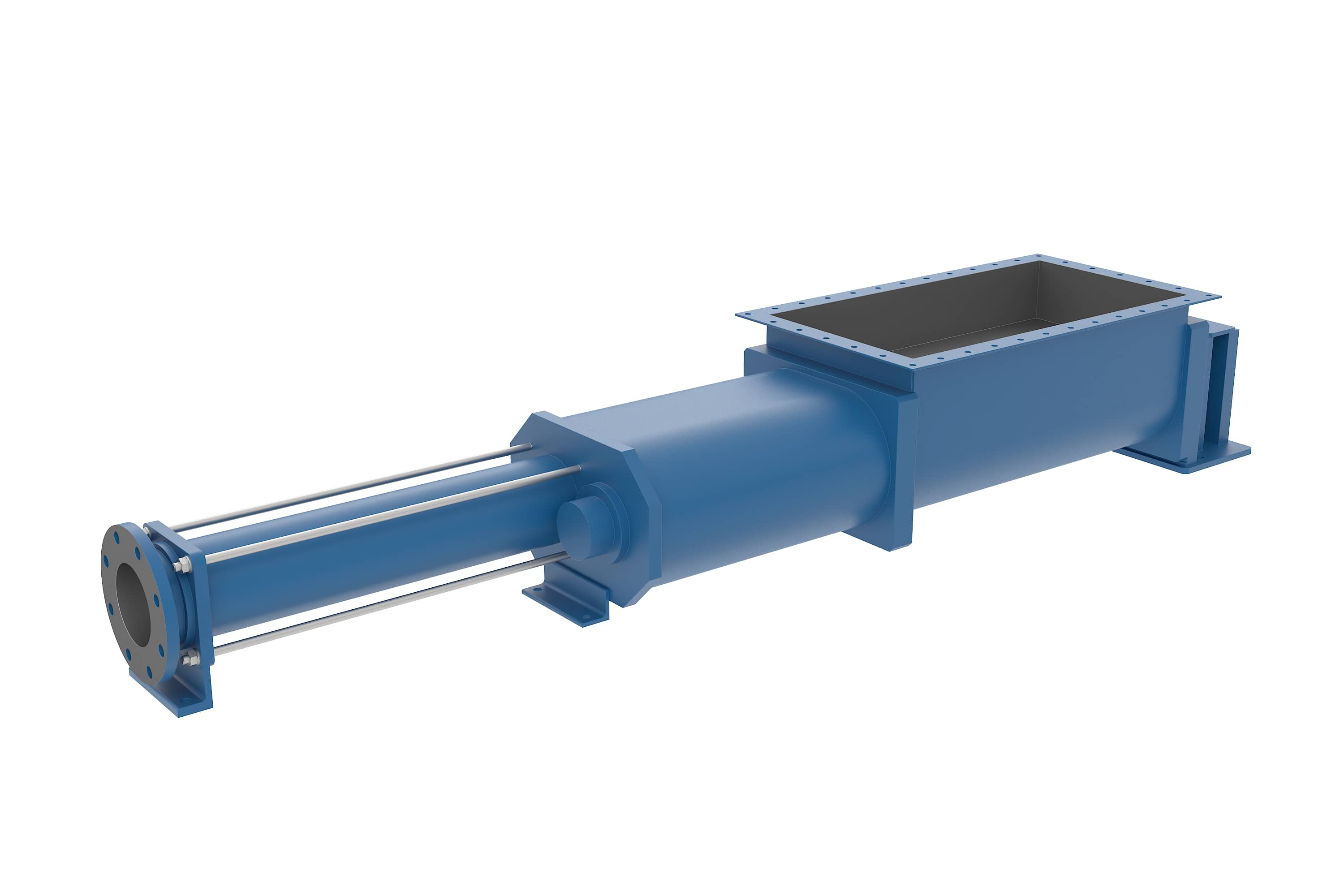

Innovative Screw and Hopper Design Optimizes Pumping Performance for Demanding Applications

Seamlessly Retrofit Marine Pumps for Biofuel Compliance and Carbon Reduction

Streamlining paint and coatings applications with precision and rapid adaptability

CIRCOR Highlights Pump Solutions for Road Grade Asphalt Binder Processing and Transfer