Twin screw pumps provide the right stuff for chemical batch processes

Twin screw pumps provide the right stuff for chemical batch processes

By Axel Jäschke, CIRCOR

Axel Jäschke, Director, Advanced Technology at CIRCOR. Mr. Jäschke is a Twin Screw Pump and Multiphase Boosting Specialist with more than 20 years’ experience in roles such as Technical Director, Head of Subsea R&D, Sales, Start Up, and Project management.

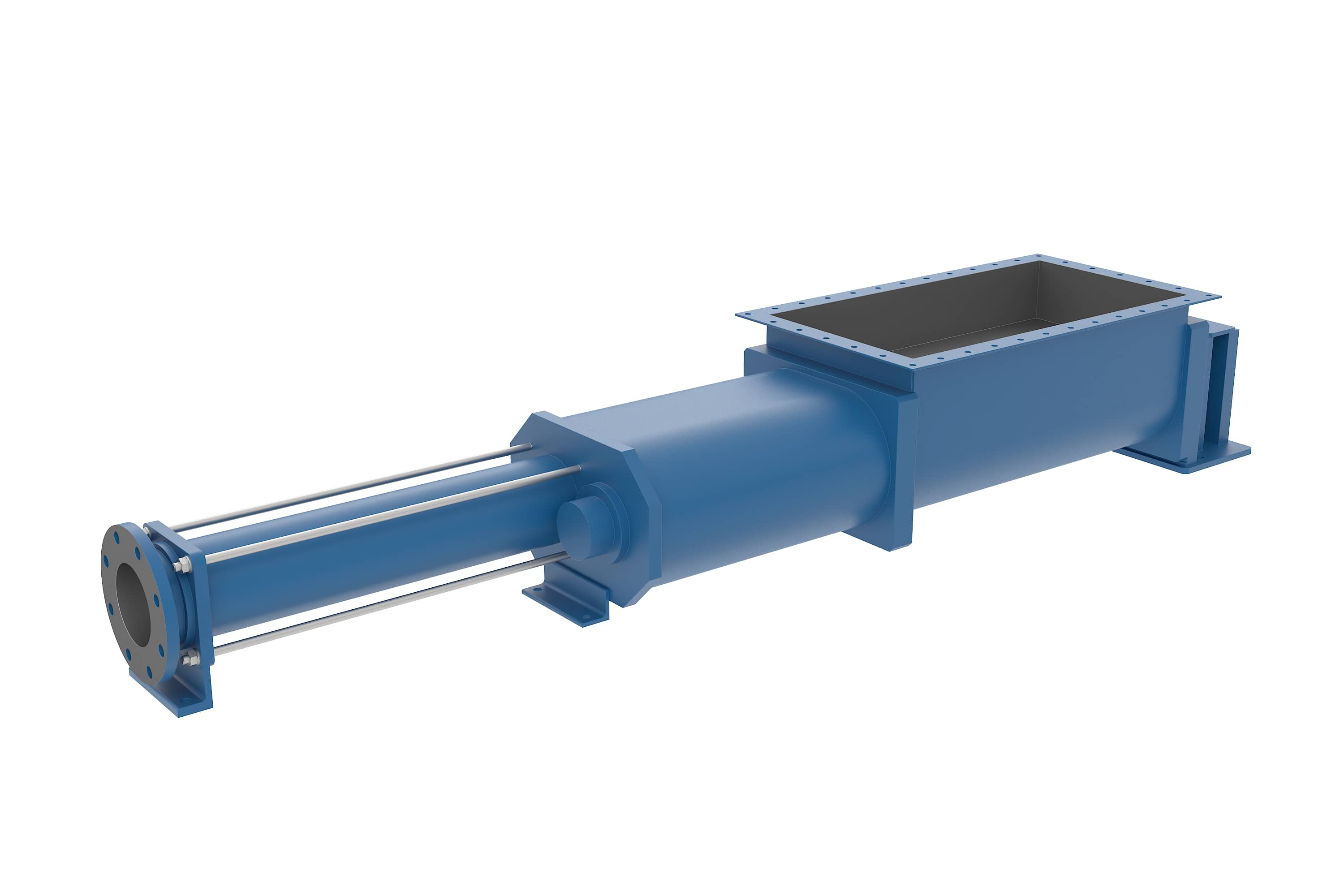

Twin screw positive displacement pumps provide performance solutions for many chemical batch processing applications that are difficult and complicated to achieve through the use of more common centrifugal pumps. Frequently, twin screw pumps are the “last resort” because they can solve many pumping challenges, but the technology is not widely known. is less. The twin screw pump itself can be more expensive compared to a centrifugal pump. However, when comparing the total cost of ownership for a system optimized for a twin screw pump against a system required to use a centrifugal pump, the twin screw pump quickly becomes a commercially attractive option. Twin screw pumps should be considered in any application where the process may involve risk of cavitation, some gas or vapor content, variations in flow, temperature, pressure, liquid characteristics or viscosity. Twin screw performance excels in chemical process and transfer applications that experience one or more of these variations, as well as any operating conditions that may be difficult or push the limits of other more common pumps.

Twin screw designs in chemical processing applications are capable of flow rates up to 3,000 m3/h, differential pressures that exceed 100 bar, product temperatures up to 400°C, and product viscosities 1,000,000 cP, making them a very robust piece of machinery. They are capable of handling a variety of process conditions that exist in the chemical manufacturing and processing industry. Dry run, self-priming, wide capacity range, flushing and cleaning and excellent flow control are just some of them.

Variable frequency drives (VFD) are state of the art technology today and a very strong supporting technology for twin screw pumps. Using a VFD today allows users to leverage the full flexibility of the twin screw pump, since the pump capacity depends dominantly on speed and is not much affected by the differential pressure. Using the VFD now allows users to easily to utilize the full performance range from 10% up to 100% of the design speed and capacity range.

When evaluating total cost of ownership during start-up, operation, maintenance and shut down, a twin screw pump may well prove to be the most economical solution.

Understanding the Benefits of Two Screw Technology

Twin screw pumps are capable of handling multiple liquids or products over extended viscosity ranges during batch processing. They can also contend with a wide range of liquid characteristics - such as lubricating, non-lubricating, corrosive, and abrasive liquids - in addition to liquids containing entrained gas.

A centrifugal pump’s impeller creates an area of low pressure at the impeller’s eye. When pumping a fluid containing entrained gas, the gas will separate and collect at this point. This phenomenon, known as vapor locking, happens when gases at the eye restrict liquid flow through the impeller. The only way to correct vapor locking is to remove the gas. This involves stopping the pump, removing the air from the system, and repriming the pump.

Twin screw and rotary positive displacement pumps are volumetric machines and not limited in this aspect. Entrained gas entering the pumping cavity is displaced with the fluid discharged from the pump as the pump discharge is isolated from pump suction.

A second benefit offered by twin screw pumps is energy efficiency. Twin screw and other rotary positive displacement pumps’ volumetric efficiency increases as the viscosity increases. This is due to the internal clearances’ becoming more effective in sealing the pumping cavity. Due to their design, centrifugal pumps will experience a loss of capacity and efficiency as viscosity increases. Internal friction losses in a centrifugal pump will increase as the viscosity increases, resulting in reduced capacity, head development and efficiency. Centrifugal pump capacity will also vary as the system pressure changes, resulting in the need for additional controls such as control valves and variable speed drives.

Twin screw pumps offer an extremely low net positive suction head (NPSH) requirement. This allows users to pump different liquids with one pump design. A twin screw pump offers low NPSH because it reduces the resistance to flow of the liquid entering the pumping chambers; with higher resistance to flow you generate higher pressures drops and the likelihood of cavitation. Specific design features of a twin screw pump that reduce a liquid’s resistance to flow include: divided flow paths that split the incoming fluid to opposing ends of the case, lower axial speeds within the pumping chamber which are a function of the pump rotational speed and selected screw pitches, and the avoidance of fluid acceleration during the pumping process.

A typical batch process may involve a change in the characteristics of the product and components of the pumped material as the batch process progresses. Each type of product requires a unique range of pressures and temperatures during batch processing to initiate the appropriate chemical reactions. The reactions typically require a pump that can circulate the product from the reactor vessel through a heat exchanger, and then back to the vessel. As such, the pump must be able to handle the full range of product viscosities as it changes from the reactant’s characteristics to the final product and be capable of emptying the reactor after each batch.

Low NPSHR and run-dry capabilities become important at this stage because any product left in the reactor is not available for further use. Pumping out the reactor with a very low liquid level and emptying it with gas slugs, plus the ability for the pump to run dry can increase plant efficiency and profitability. A twin screw pump’s properly-designed mechanical seal support and internal clearances maintained by rigid timing gears allow it to handle this process requirement. This makes the twin screw pump capable of pumping the low viscosity fluids involved in solvent or caustic cleaning cycles in addition to the higher viscosity final products created in the reactor, making it a unique piece of pumping machinery.

Additional Design Considerations

Twin screw pump designs offer optional jacketing for the pump body and stuffing box housings, adding additional operational flexibility during start up, shut down, cleaning cycles and upset conditions. Screw profiles and pitches can be customized to meet specific operating requirements, delivering application-specific efficiency not attainable in other pumping technologies. Stuffing boxes can also be customized to provide multiple industry standard seal plans. Many models include a rotor design that offers a back pull-out feature to aid inspection and maintenance. This eliminates the need to disturb piping or the driver.

Special hard coatings such as ceramic, chrome, nickel and cobalt based materials can also be used to add wear resistance to critical pumping surfaces such as the body bore and screws. The pump’s casing can be manufactured from any machinable alloy, depending on the application’s need for corrosion protection. Pumps have been manufactured using materials including cast iron, ductile iron, white iron, Ni-resist, steel, low-temp steel, stainless steel, duplex stainless steel and Hastelloy®.

Flow Control and Energy Recuperation

Twin screw pumps move fluid inside closed chambers formed by the screws. Consequently, the pump capacity depends directly and mainly on pump speed. Pump speed control will allow to optimize the process control. Flow control is just a function of the pump speed. As long the pump outlet pressure is higher as the inlet pressure, the pump is operating as pump and it consumes energy. When the inlet pressure however is higher than the outlet pressure, the pump acts as a hydraulic motor and recuperates the hydraulic energy provided by the process. It acts as power recuperating throttle or, we could say, it is an Energy Recuperating flow or pressure Control Valve (ERCV). Instead of wasting hydraulic energy in conventional control valves, twin screw machines can extract hydraulic energy from the process fluid and feed it back into the power grid – while, at the same time being able to handle all the challenging fluid properties and process advantages the twin screw pump stands for.

Robust Capability

Understanding the requirements of each application is the key in sizing and designing these heavy-duty robust pumps. The design concept must include conditions experienced during start-up, operation (full range), maintenance and shut down. System designers should work together with the pump manufacturer to fully understand the total process so that maximum benefits are achieved. Each application is unique, which may alter the design of the twin screw pump to allow for such options as special clearances, special coatings, flange ratings, mechanical seal arrangements, suction and discharge nozzle locations, instrumentation and other components. This high grade of customization allows the twin screw pump to operate in specific process conditions which are individual and proprietary to each production facility.

According to API 676 twin screw pumps are non-contacting pumps. This is correct - however, there exist two variations of non-contacting. For all low viscosity, dry run or gas handling applications, the fully, mechanical non-contacting design is recommended. It is the most robust pump design and can handle virtually all process fluids without rotor-liner contact. If the process fluid allows a lubricating support between rotors and liner (like in gears or 3-screw pumps, etc.), the twin screw pumps can be optimized for higher efficiency by reducing the radial clearances of the screws and using the hydrodynamic support film to avoid metal-to-metal contact. This design is highly reliable, robust and efficient, while operating the design process fluid. Hybrid solutions can accept some gas or flushing fluids at lower pressures (clean in place, self-priming) while still maintaining a high efficiency when operating at the design process conditions.

Because twin screw pumps can handle the full performance range required and they can be manufactured in high temperature, corrosion resistant and abrasion resistant designs, these pumps should be a “first choice” in batch processing applications. Specific chemical processing applications that can benefit from the use of twin screw pumps include the manufacture of polymer adhesives, polymer sealing solutions, polymer cements, structural foams and pelletized polymers that are used to create products such as carpet threads, carpet backing, pen grips, knobs, packaging, personal care products, interior and exterior automotive components and thousands of other commercial and industrial products.

These are not “off the shelf” solutions – but then, how many “off the shelf” chemical batch processing applications are there?

Innovative Screw and Hopper Design Optimizes Pumping Performance for Demanding Applications

Seamlessly Retrofit Marine Pumps for Biofuel Compliance and Carbon Reduction

Revolutionizing Filtration Workflow with Zenith Metering Systems

Streamlining paint and coatings applications with precision and rapid adaptability