Product Search

Real-world sizing and selection tool for a variety of the most popular pumps across the CIRCOR portfolio.

Search

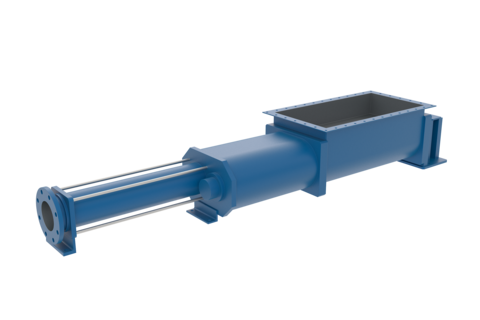

For handling viscous, abrasive or solids-laden materials in various industrial applications. Their unique hopper design enables efficient and smooth product transfer in this tough environment.

1.700

Max. Differential Pressure [bar] :36

Max. Fluid Temperature [°C] :135

Max. Solid Content [%] :45

Max. Viscosity [mm²/s] :1.000.000

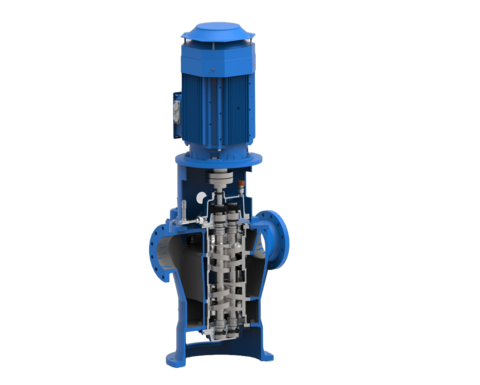

Tailor-made for demanding cooling water circulation tasks in large diesel engines. Driven directly by the transmission, they provide efficient and reliable cooling.

550

Max. Delivery Head [m] :150

Max. Outlet Pressure [bar] :16

Max. Fluid Temperature [°C] :120

Instead of wasting unused energy as heat, the ERCV uses an innovative combination of a volumetric screw-machine and advanced actuator technology to recover unused hydraulic energy.

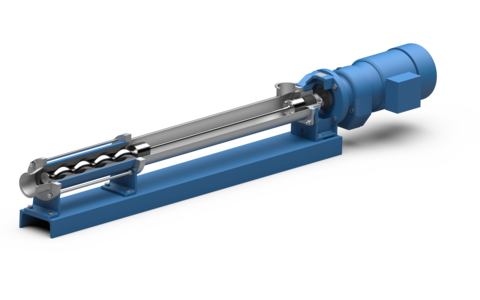

Designed to minimize the risk of fluid contamination and provide an efficient solution for the transfer of lithium slurry.

500

Max. Diff. Pressure [bar] :12

Max. Fluid Temperature [°C] :100

Max. Solid Content [%] :60

Max. Viscosity [mPas] :300.000

Optimized for dry running, stripping and self-priming to ensure low NPSH requirements. In addition, low, medium and high pressure versions are available and the pumps are available for CIP.

5.000

Max. Diff. Pressure [bar] :60

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

MFG in Monroe NC USA

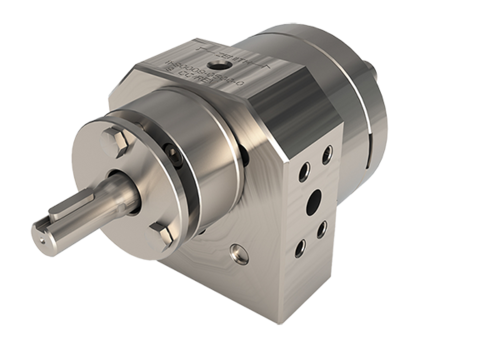

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500

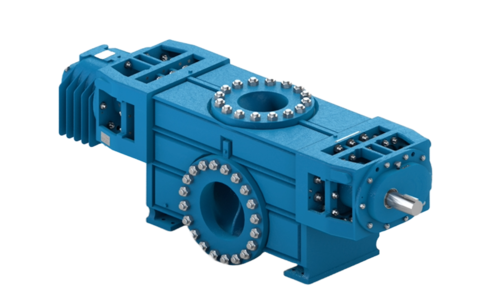

Flexible, durable and efficient; a heavy-duty pump built to perform and handle differential pressures up to 800 psi. Its adaptability makes it a perfect fit for a wide range of applications including chemical processing, petroleum refining, power generation, food handling or barge unloading.

1,000

Max. Flow Rate [GPM] :4,800

Max. Viscosity [mm²/s] :100,000

Max. Fluid Temperature [°F] :750

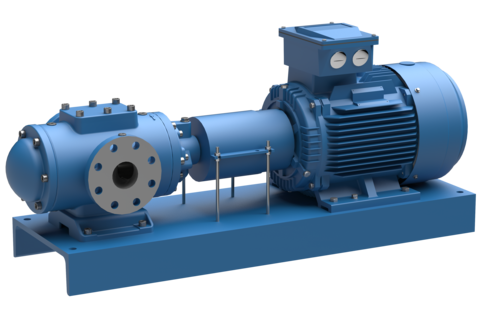

Decades of optimized reliability, efficiency and adaptability. The self-priming pump features hardened and polished spindles which are running in a replaceable liner.

5.300

Max. Outlet Pressure [bar] :120

Max. Fluid Temperature [°C] :250

Viscosity Range [mm²/s] :3-5.000

Suitable for the requirements of the chemical and refinery industries. Thanks to the modular design of the pumps, they can be optimally adapted to the specific and demanding requirements.

2.500

Max. Diff. Pressure [bar] :40

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

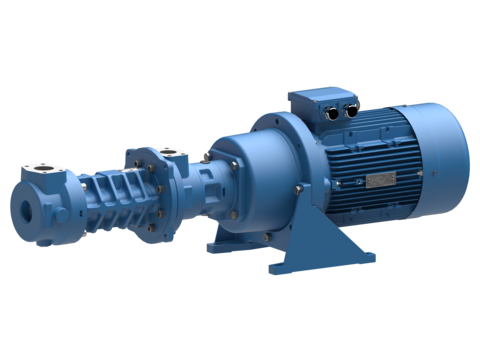

Optimal solution for high-pressure coolant supply in machine tools. The three-screw pump is an essential element in the effective distribution of coolants and protective agents up to 100 bar.

1.000

Max. Inlet Pressure [bar] :10

Max. Outlet Pressure [bar] :120

Max. Fluid Temperature [°C] :80

Viscosity Range [mm²/s] :1-2.000

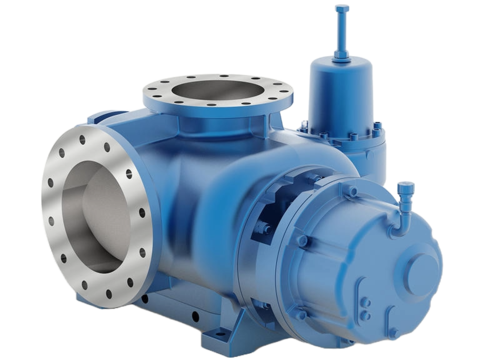

Designed specifically for the efficient transfer of fuel oil, lubricating oil, and hydraulic oil. Their versatility makes them the optimal choice for demanding applications, such as pumping low-sulfur marine fuels or marine diesel (MGO).

112

Max. Inlet Pressure [bar] :25

Max. Outlet Pressure [bar] :40

Max. Fluid Temperature [°C] :150

Viscosity Range [mm²/s] :1-3.000

Self-priming side channel pumps are used for pumping aggressive and mechanically clean liquids, especially for small flows and high heads.

36

Max. Delivery Head [m] :350

Max. Suction Head [m] :7

Max. Outlet Pressure [bar] :40

Max. Fluid Temperature [°C] :220