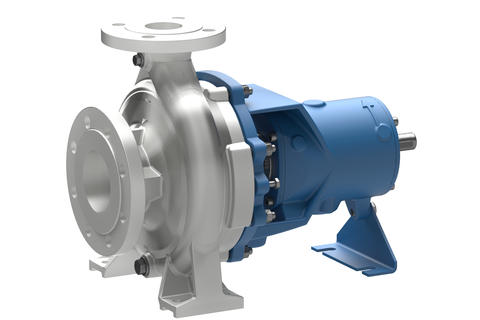

ALLCHEM® Series

Unbeatable Versatility for Chemical Applications

ALLCHEM® centrifugal pumps are used in a wide variety of processes in the chemical and process industries. But they are also indispensable in other industries when it comes to safely and efficiently pumping aggressive or corrosive, hot or cold, clean or solids-laden media. The single-stage, single-entry design complies with DIN EN ISO 2858 and DIN EN ISO 5199 standards and guarantees the highest performance and safety. With our ALLCHEM® pumps you can be sure that your pumping tasks will be solved efficiently.

High Efficiency & Reliability

Low operating costs due to optimized hydraulic components with excellent efficiency, NPSH values & very stable shaft system

Versatility

Adapt to a wide range of applications

Modular System

Simplified and cost-effective spare parts storage

Safety is paramount in the chemical industry, where the handling of hazardous fluids is commonplace. That's why our ALLCHEM® centrifugal pumps are designed to keep your operation safe. Due to their stability and the short distance between the pump-side bearing and the shaft seal, concentricity is achieved, creating optimum conditions for the shaft seal. This guarantees a long service life, high operational reliability and low operating costs.

In addition, ALLCHEM® centrifugal pumps are designed to handle hazardous and corrosive substances reliably and with a long service life. ALLCHEM® centrifugal pumps comply with the technical requirements of DIN EN ISO 5199, meeting the highest demands of the demanding chemical industry.

Flexible Adaptation to Your Needs

Thanks to the modular system, ALLCHEM® centrifugal pumps can be adapted to your individual needs. You can choose from a wide range of materials and shaft seals, and customize the pumps to meet even the most demanding process-specific requirements.

The flexibility of our chemical centrifugal pumps allows you to equip them for high or low temperature applications, with single or double mechanical seal and with heating and cooling options, depending on the needs of your plant. Different pressure ratings (PN16 and PN25) and flange designs according to different standards can also be implemented to match the system. In addition to the horizontally mounted CNH-B series, in which the pump and drive motor are coupled on a common baseplate, we also offer the CNB block pump series, which can be installed horizontally or vertically and is ideal for limited installation space.

| Series | Specifications | Max. Capacity [m³/h] |

Max. Delivery Head [m] |

Max. Outlet Pressure [bar] |

Max. Fluid Temperature [°C] |

|---|---|---|---|---|---|

| CNH-B | Dry installed, horizontal, single-stage, single-entry, volute casing centrifugal pump in process design according to DIN EN ISO 5199 and DIN EN ISO 2858 with supplementary sizes |

1.200 | 147 | 25 | 350 |

| CNB |

Dry-installed, horizontal, Casing dimensions and |

240 | 100 | 25 | 160 |