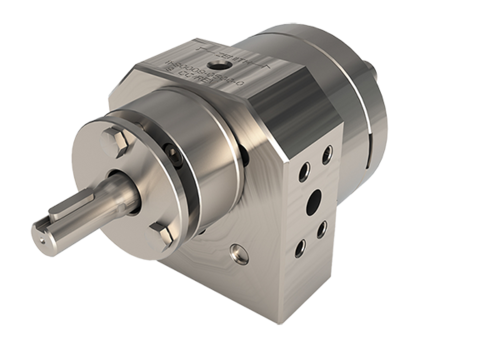

ZENITH 9000 Series

MFG in Monroe, NC USA

Discover the 9000 series metering pumps, designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design. These pumps are suitable for a wide range of fluids, including those that are abrasive or have poor lubrication. With their exceptional performance, the 9000 series metering pumps are used in various industries worldwide, including food and beverage, chemical, fiber, pharmaceutical, and paint facilities.

In addition to their precision and reliability, the C-9000 pumps are available with a magnetic drive (mag-drive) sealing option. This innovative feature eliminates shaft leakage of fluids, improving plant safety while reducing VOC emissions and seal failures. With the magnetic coupling feature, excessive mechanical seal failures and the need for buffer fluids are eliminated, resulting in less downtime and improved operational efficiency. Choose the 9000 series metering pumps with mag-drive sealing for a safe, reliable, and hassle-free pumping solution.

Precision Gear Pumps

Product Performance You Can Rely On

Precision gear pumps are an integral part of many manufacturing processes requiring metering, mixing, dispensing, coating, and extruding, where accuracy and uniformity of flow are critical. That’s why manufacturers in industries from manmade fibers and polymers to food and medical devices have relied on Zenith gear pumps since 1926. With high metering accuracy, pulse-free flow, and long wear life across a wide range of fluid and pressure conditions, the Zenith Pumps brand is synonymous with high performance and reliability.

In addition to standard product offerings, Zenith can provide custom-engineered pumps for demanding services, such as submersible, flushable, and sanitary applications. Backed by the resources of CIRCOR Engineered Systems group, Zenith Pumps can provide a complete custom-engineered system along with the pump, from the tank to the controls, letting you focus on your core competency while we develop a fluid handling, mixing, or metering system aimed at providing the highest precision and reliability possible.

- Stable, repeatable flows are assured under varying conditions of temperature, viscosity and pressure.

- Unique design offers virtually pulseless flow without valves or flexible elements that add complexities, increase cost and hinder performance.

- A variety of pump heads and drive combinations are pre-configured to provide you a range of standard options.

- Unparalleled mechanical precision, combined with closed-loop accuracy, ensures exact volume per revolution without expensive flow meters.

- Only three moving parts and hardened abrasion resistant materials provide excellent wear, corrosion and self-lubricating performance.

- Years of practical application experience, backed by a technical staff with a variety of technical credentials, eliminates the guesswork.

No one has more experience or material options for dispensing sealants and adhesives than Zenith. Contact us to determine what material option is best for you.

Product Models & Specifications:

| B-9000 | C-9000 | H-9000 | |

| Typical Service: | General Chemical | Corrosive / Poor Lubricity | Abrasive / High Temperature |

| Materials: | 400 Series Stainless Steel | 316 Stainless Steel | Tool Steel |

| Outlet Pressure: | Up to 1,000 psi (70 bar) | Up to 1,000 psi (70 bar) | Up to 2,500 psi (175 bar) |

| Max. Operating Temperature: | 645 °F | 350 °F | 950 °F |

| Flow Rate: | Up to 27,000 cc/min | Up to 9,000 cc/min | Up to 27,000 cc/min |

|

Fluid Properties: |

Good Excellent Mildly Corrosive 1 cps or greater |

Poor Good Excellent Corrosive 0.3 cps or greater |

Abrasive |

Construction features

Three different levels of material options are available for handling general purpose, corrosive or high temperature/abrasive applications. These options include:

- 400 stainless (B series)

- tool steel (H series)

- 316 stainless with optional stellite

- silicon carbide coatings (C series)

Other data

Design standard: Manufacturer STD

Fluids: Acids, Additives, Bases, Coatings, Flavorings, Fuel, Solvents, Perfumes, Pharmaceuticals, Oils, Cosmetics

Sealing: Lip seals, Single Mechanical seal, Magnetic coupling

- Typical Service: Corrosive / Poor Lubricity

- Materials: 316 Series Stainless Steel

- Outlet Pressure: Up to 1,000 psi (70 bar)

- Max Operating Temperature: 350 °F

- Flow Rate: Up to 9,000 cc/min

- Fluid Properties: Lubricity Poor / Good / Excellent

- Viscosity: Corrosive 0.3 cps or greater

Max. gpm: 2.40

Max. lpm: 9.08

Max. m³/hr: 0.55

Max. bar (dp): 68.95

Max. psi (dp): 1,000.00

Max. cSt [mm²/s]: 2,000,000.00

Min. cSt [mm²/s]: 0.30

Min. SSU: 13.70

Max. °C: 177.00

Max. °F: 350.00

Min. °C: -40.00

Min. °F: -40.00

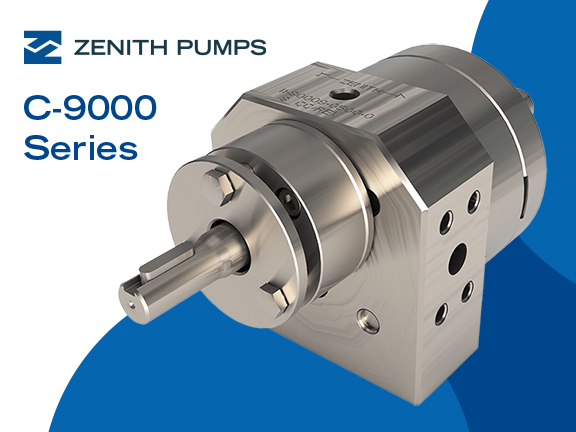

C-9000 Series Precision Gear Pumps

Precision Pumping Built for Clean-in-Place Processes

Advanced Gear Pumps for Hygienic Efficiency

Zenith is known for its precision gear pumps which are widely used by general industrial, food and beverage and medical manufacturers. The C-9000 series provides additional benefits by supporting CIP processes. Leaving the gear pump in place during the cleaning process allows customers to save time by avoiding manual cleaning of the pump.

Trust Zenith for Your Metering Solutions

Engineered Pump Solutions to Dose Your Ingredients

Whether you are spraying, blending or injecting your fluid material, repeatability is of paramount importance. Zenith products assure accurate metering over a wide range of applications and process fluid conditions. Add a drive system and incorporate a closed-loop speed controller to maintain metering accuracies of +/- 1 percent.

In addition to accurate delivery, close tolerance precision gear metering pumps with only two moving parts are reliable in service and have virtually pulse-free fluid performance. A gear metering pump’s tight internal clearances are as small as 50 millionths of an inch, ensuring a consistent flow rate and high-pressure capabilities where they are needed the most.

Delivering engineering and design expertise for solutions that address unique process requirements and save time and money.