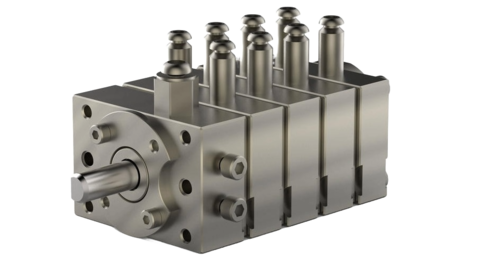

ZENITH Spin Finish Series

Providing precise, pulse free flow for finishing solutions on synthetic fiber and monofilaments

MFG in Monroe, NC USA

The Spin finish pumps are used to meter finishing solutions in a precise, pulse free flow to be applied onto synthetic fiber and monofilaments such as polyester, nylon, polypropylene, acetate and rayon. Spin finish metering pumps are available in a wide range of capacities and number of discharge ports.

Precision Gear Pumps

Product Performance You Can Rely On

Precision gear pumps are an integral part of many manufacturing processes requiring metering, mixing, dispensing, coating, and extruding, where accuracy and uniformity of flow are critical. That’s why manufacturers in industries from manmade fibers and polymers to food and medical devices have relied on Zenith gear pumps since 1926. With high metering accuracy, pulse-free flow, and long wear life across a wide range of fluid and pressure conditions, the Zenith Pumps brand is synonymous with high performance and reliability.

In addition to standard product offerings, Zenith can provide custom-engineered pumps for demanding services, such as submersible, flushable, and sanitary applications. Backed by the resources of CIRCOR Engineered Systems group, Zenith Pumps can provide a complete custom-engineered system along with the pump, from the tank to the controls, letting you focus on your core competency while we develop a fluid handling, mixing, or metering system aimed at providing the highest precision and reliability possible.

- Longer Life: Proprietary High Vanadium Stainless Steels and other best-in-class materials are used to dramatically increase the wear and corrosion resistance of the pump.

- Uniform Accuracy: The application of new design criteria insure that all the internal components wear uniformly over the life of the pump – no stream will loose its accuracy before any other.

- Less Bubble Formation: The use of special Parker fittings, provide a constant port size from the pump, through the fitting and into the tubing, with a special O-ring seal to eliminate stagnation and air drawn bubble formation.

- Reduced Bacterial Growth: The optimized internal porting eliminates fluid stagnation points where bacterial growth happens.

- Easier Maintenance: Our registered deck design, removable seals, and optional color coded fittings and hoses, redefine "quick-n-easy" pump assembly.

- Value: Long life, ease of maintenance, and improved product quality convert the affordable price into a great value!

Spin finish pumps are used to meter finish solutions in a precise, pulseless flow to be applied on man-made fibers such as polyester, nylon, polypropylene, acetate and rayon. Spin finish metering pumps are available in a wide range of capacities and number of discharge ports and are suitable for most man-made fiber finishing solutions.

Pump Type: Rotary external spur gear

Rotation: Clockwise Operating 10-100 rpm recommended.

Contact Speed: Factory for specific recommendation based on your application conditions

Temperature: To 212 ˚F (100 ˚C)

Flow Rates: 0.03 to 1.2 cc/rev/port 2 to 12 discharge ports standard

Inlet: 7 psi maximum, flooded suction required; differential pressure should be kept near zero for water emulsion finishes

Viscosity: 1 to 100 cp

Porting: Plates port to same side; Parker Prestolok fitting adapters supplied for flexible tubing (Inlet - 6 mm OD, Outlet - 4 mm OD)

Materials of Construction: Proprietary High Vanadium Stainless Steel provides best-in-class corrosion and wear resistance; seal and binder screws, alloy steel

Seal: Stainless steel spring energized Nitrile lip seal standard