ALLFUEL® Series

Unleash Efficiency with the 2nd Gen Oil Transfer Pumps

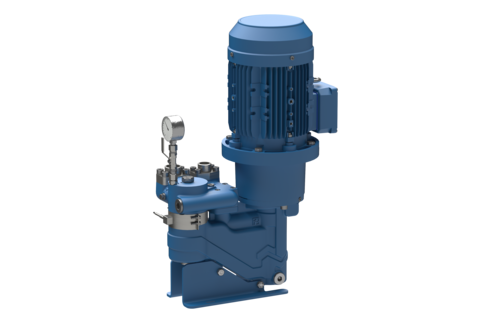

The 2nd generation of the Allweiler ALLFUEL® series was designed specifically for the efficient transfer of fuel oil, lubricating oil, and hydraulic oil. The ALLFUEL® three-screw pumps are recognized worldwide for their reliability as transfer, booster, and burner pumps in oil firing technology, fuel systems for marine vessels, as well as transfer and filling pumps in tank farms and lube oil pumps throughout all industrial sectors, operating at pressures up to 40 bar.

Their versatility and performance make three-screw pumps the optimal choice for demanding applications, such as pumping low-sulfur marine fuels or marine diesel (MGO). The ALLFUEL® series offers various designs, including models with either mechanical seal or magnetic drive for maximum safety. Regardless of the version you select, you can count on constant and secure pumping of your media.

Key Advantages

Fast Maintenance

Only one third of the time thanks to easy (dis)assembly of the pump insert

Long Service Life

External bearing, wear-protected SiC/SiC mechanical seal or magnetic coupling, patented new hydraulic system with inverted comb bearing and integrated thrust compensation

High Efficiency

Even with demanding, low-viscosity fuels such as low-sulfur MGO

Continuity

Fits into most housings of the old SPF or ALLFUEL series

ALLFUEL® Three-Screw Pumps

Next-Gen Innovation for Maximum Uptime

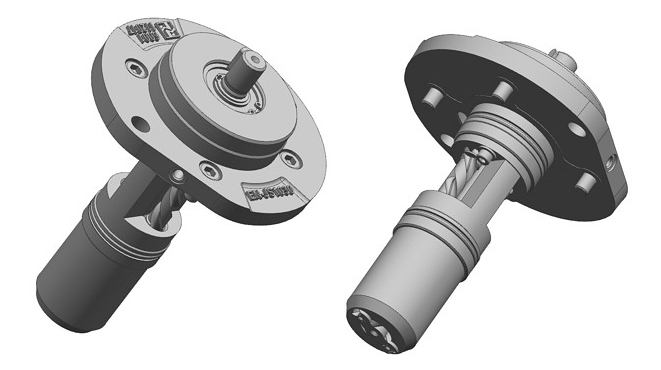

The 2nd generation ALLFUEL® three-screw pumps boasts an innovative, user-friendly design that minimizes downtime. Our one-piece insert unit simplifies maintenance and cuts down repair time by one-third. Besides being easy to install, the insert unit is incredibly durable due to its external bearing, which never touches the pumped medium.

Our wear-protected SiC/SiC mechanical seal or magnetic coupling ensures a longest-lasting sealing. The new patented hydraulic system with an inverted comb bearing and integrated thrust compensation is highly durable.

Effortless Switching and Easy Cleaning

The Ultimate Filter Innovation

A central ball valve with a straightforward direction setting makes switching easy. Our innovative design ensures efficient flow through the filter from the inside out, keeping dirt and metal chips securely inside and preventing them from entering the pump housing.

A notable feature of our filter is its easy cleaning. It can be easily extracted without requiring the medium to be drained. This pragmatic approach saves time and ensures seamless operations for your processes.

| Series | Specifications | Max. Capacity [l/min] |

Max. Inlet Pressure [bar] |

Max. Outlet Pressure [bar] |

Max. Fluid Temperature [°C] |

Viscosity Range [mm²/s] |

|---|---|---|---|---|---|---|

| AFI | SiC/SiC mechanical seal | 112 | 6 | 40 | 150 | 1 - 3,000 |

| AFI-F | SiC/SiC mechanical seal and filter | 112 | 6 | 40 | 150 | 1 - 3,000 |

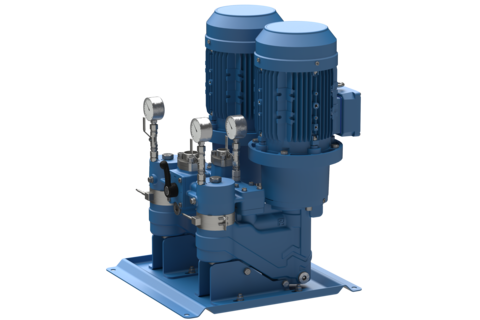

| AFI-T | Twin unit with SiC/SiC mechanical seal and filter | 112 | 6 | 40 | 150 | 1 - 3,000 |

| AFM | Magnetic coupling | 112 | 25 | 40 | 150 | 1 - 750 |

| AFM-F | Magnetic coupling & filter | 112 | 25 | 40 | 150 | 1 - 750 |

| AFM-T | Twin unit with magnetic coupling and filter | 112 | 25 | 40 | 150 | 1 - 750 |