Houttuin Multiphase Series

Improved Oil Production & Controlled Pressure

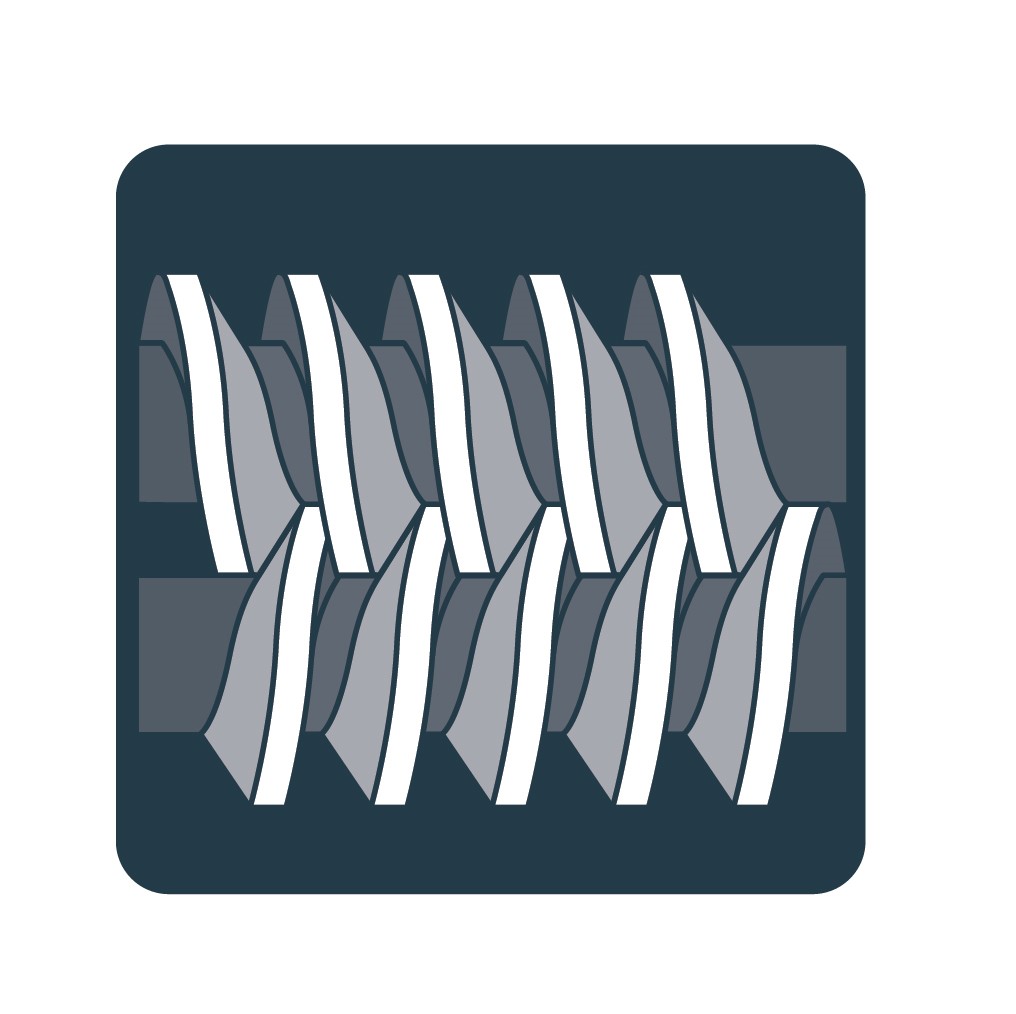

Our multiphase pumps (=MPP) are an excellent solution for the demanding requirements of the oil and gas industry under changing operating conditions. These compact, rugged pumps are designed for stand-alone operation in remote oil fields. The housings are rated for pressures up to 150 bar (900#). They can pump up to 97 % gas continuously and switch from 100 % liquid to 100 % gas in seconds in slug flow mode.

An outstanding feature of HOUTTUIN MPPs is their wide speed range. This unique feature allows the operator to adjust liquid and gas flow as needed to ensure precise control of pipeline and wellhead pressures. Regardless of the selected speed and gas content, these pumps will always deliver the required pressure.

Any Liquid

Any Viscosity

Low NPSH-Requirements

Excellent Efficiency

The Role of Multiphase Pumps

Demanding Requirements in Remote Oil Fields

Operating in remote oil fields requires adaptability and reliability. Not only are they rugged, but they are also capable of seamlessly integrating pumping and compression operations to meet dynamic requirements. A remarkable capability of MPPs is to handle the transition from liquid to gas flows almost effortlessly - in seconds or minutes. This impressive speed and flexibility make them the ideal choice for environments where up to 95 % gas is required.

Increasing Oil Production Through Pressure Control

The primary function of MPP twin-screw pumps is to regulate and stabilize pressure at the wellhead to optimize the overall oil production process. These pumps can be strategically located at either the main manifold or the central pump station. They can be seamlessly integrated in parallel configurations to improve flexibility, efficiency and redundancy. Maximum efficiency is achieved when MPPs are positioned as close to the wellhead as possible to maximize well performance.

Liquids & Gases in Harmony

Unlike conventional pumps, MPPs orchestrate the harmonious interaction of liquids (hydrocarbons and water) and gases (or hydrocarbon vapors). This innovative integration allows these pumps to pump and compress simultaneously, overcoming traditional limitations. The adaptability of MPPs is demonstrated by their response to variations in inlet pressure, allowing efficient adjustment of the required flow rate due to the compressibility of the gases.

| Series | Specifications | Max. Capacity [m³/h] |

Max. Differential Pressure [bar] |

Max. Fluid Temperature [°C] |

Viscosity Range [cSt] |

|---|---|---|---|---|---|

| 340.MRC | Higher gas contents and higher pressure due to its slim casing design and vertical, integrated separator tower |

5.000 | 60 | 120 | 0.5 - 100,000 |