Twin-Screw Pump Technology

Learn everything about the versatile pump technology.

Definition

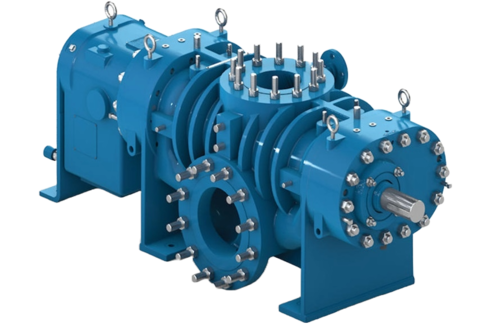

What are Twin-Screw Pumps?

Twin-screw pumps (TSP) are heavy-duty, general-purpose pumps used in a wide variety of applications. Excellent flow control with the highest efficiency over a wide operating range for almost all types of fluids and fluid viscosities make these pumps unique. TSPs are self-priming pumps with excellent suction lift, smooth operation and very low NPSH requirements. The ability to clean in place (CIP) is not the only way to simplify processes, improve product quality and reduce operating costs.

A unique feature of TSPs is their ability to provide constant flow regardless of system pressure requirements. Pump flow rate is a function of pump speed – the pump pressure is a function of the hydraulic system response. Whatever pressure the system requires, the pump will support any pressure up to its rated pressure at any speed. Furthermore, the pump only needs the energy related to actual flow and actual pressure requirements of the hydraulic system. As a result, the pump always operates at its highest efficiency. The pump is not limited to operating close to its design point but can operate safely and efficiently across its wide operating range.

Technology

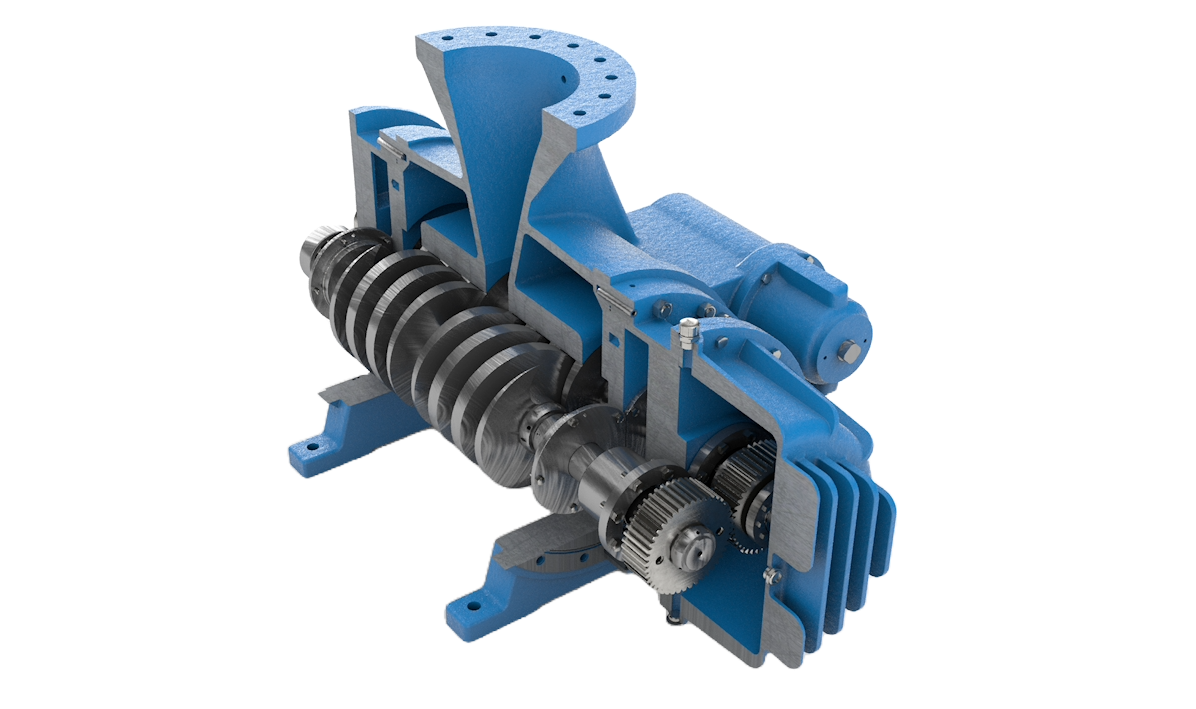

How do Twin-Screw Pumps work?

Twin-Screw Pumps per API 676, model code SMT, are timed screw pumps with symmetrical screw twins. Twin-Screw Pumps with two screw-twins (our 200 series) provide axially hydraulically balanced, contact-free rotors. By eliminating the need for the screws to transmit torque, the screw profiles are optimized for smooth and efficient fluid handling without high turbulence, mixing and acceleration forces. Single-screw twin TSPs are smaller, less expensive and very compact, yet non-contacting pumps (our 100 series) optimized for very gentle movement of sensitive fluids.

Twin-screw technology is not limited to pumps. While the most common and well-known technology is the twin screw pump, in some configurations the TSP acts more like a compressor and can be used for multiphase fluids - called a multiphase pump (MPP). The twin-screw can also operate as a hydraulic motor (twin-screw motor, TSM). Using the TSM to control flow - like a control valve - can replace conventional CVs.

Watch the video to see how twin-screw pumps work.

Benefits

Advantages of Twin-Screw Pump Technology

Twin-screw technology offers many advantages that make it the preferred choice in many industries. The twin-screw pump supports your process and does not require your process to support the pump’s operation.Simplify your system by eliminating components you need today to support your centrifugal pump.Control your process with just one twin-screw pump.

The versatility of twin-screw technology lies in its ability to handle a wide range of liquids, from thin, watery solutions to highly viscous and dense substances such as molasses or heavy oils. Unlike traditional pumps that struggle with varying fluid consistencies, twin-screw pumps excel at handling this diversity. This capability is critical for industries that use a variety of fluids in their processes, ensuring seamless operations and consistent output quality.

One of the remarkable aspects of twin-screw technology is its adaptability to fluids with a wide range of viscosities. Whether the fluid is as thin as water or as thick as honey, these pumps maintain a consistent flow rate. This versatility is invaluable in industries where the viscosity of the fluid being processed can change, ensuring reliable performance and preventing production interruptions.

Net Positive Suction Head (NPSH) is a critical factor in pump performance. Twin-screw pumps have exceptionally low NPSH requirements, which means they can operate effectively even when the available inlet pressure is minimal. This feature prevents cavitation, a phenomenon that can damage conventional pumps, and ensures stable and continuous operation. Industries benefit from reduced maintenance costs and longer pump life.

Twin-screw pumps are designed for exceptional fluid-handling efficiency. Their precision-engineered, intermeshing screw design minimizes internal losses and maximizes energy transfer. This efficiency not only reduces operating costs by conserving energy, but also helps to protect the environment by reducing overall power consumption. Industries that rely on twin-screw pumps experience reliable and cost-effective fluid transport, improving their overall productivity and sustainability.

Support

How to choose the right Twin-Screw Pump

Due to the wide operating and speed range and the variety of the fluid properties the pump can handle the optimal pump selection can be a bit tricky and will be done by our experts. We will also consider the specific requirements of your application and process specifics.

Our team of experts help to make the right choice.

We will work with you to review your application and determine which pump meets your needs best.

Trusted Brands

Twin-Screw Pumps from HOUTTUIN & WARREN

HOUTTUIN is one of the market leaders in compact, robust and flexible twin-screw pumps while WARREN pumps are the experts in high pressure twin-screw Pumps. The experience of more than 150 years of HOUTTUIN twin-screw manufacturing is now combined in our Center of Excellence for twin-screw Pumps – part of the ALLWEILER group in Germany and fabricated at ALLWEILER India in Daman. Your benefit is the combined experience, ALLWEILER quality and price advantage of our best cost country manufacturing strategy.

HOUTTUIN offers the widest variety of pump lines to support you with the best pump type for your application. Innovative solutions such as the ERCV, FHP, MRC, etc. will provide you with state of the art solutions for any of your process requirements – from “simple” lube oil circulation, normal handling of a wide fluid range through complex chemical applications up to the most challenging multiphase boosting requirements.

Highly efficient, robust, reliable pumps for almost all types of fluids and any type of process is what you get from HOUTTUIN and WARREN.

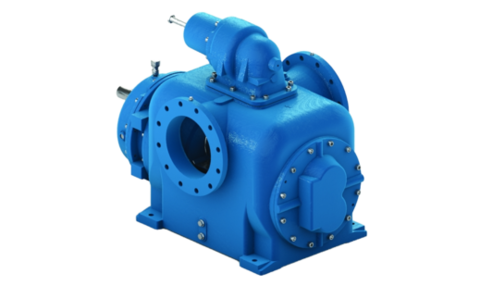

For pumping clean, lubricating fluids and lube oil applications. The HTN LO pumps provide compact, reliable solutions for high flow requirements in transport and lubrication applications.

1.000

Max. Diff. Pressure [bar] :16

Max. Fluid Temperature [°C] :80

Viscosity Range [cSt] :10-760

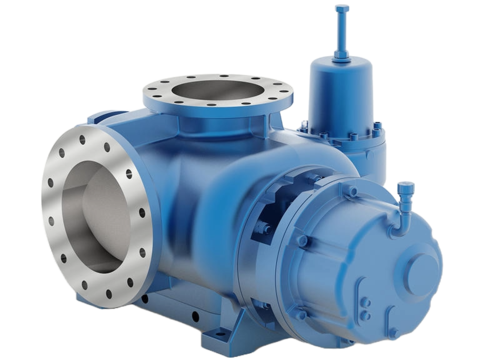

Optimized for dry running, stripping and self-priming to ensure low NPSH requirements. In addition, low, medium and high pressure versions are available and the pumps are available for CIP.

5.000

Max. Diff. Pressure [bar] :60

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5 - 100.000

Flexible, durable and efficient; a heavy-duty pump built to perform and handle differential pressures up to 800 psi. Its adaptability makes it a perfect fit for a wide range of applications including chemical processing, petroleum refining, power generation, food handling or barge unloading.

1,000

Max. Flow Rate [GPM] :4,800

Max. Viscosity [mm²/s] :100,000

Max. Fluid Temperature [°F] :750

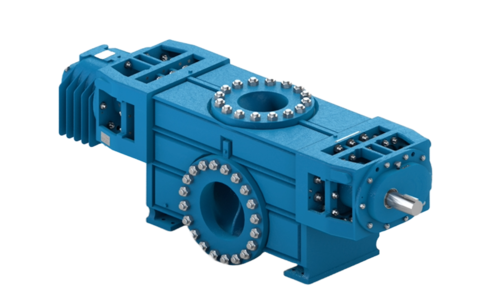

Highly efficient and built to last, these heavy-duty, high pressure pumps deliver efficient performance year after year and are perfectly suited for a wide range of applications in the oil and gas industry.

1,400

Max. Flow Rate [GPM] :4,500

Max. Viscosity [mm²/s] :100,000

Max. Fluid Temperature [°F] :225