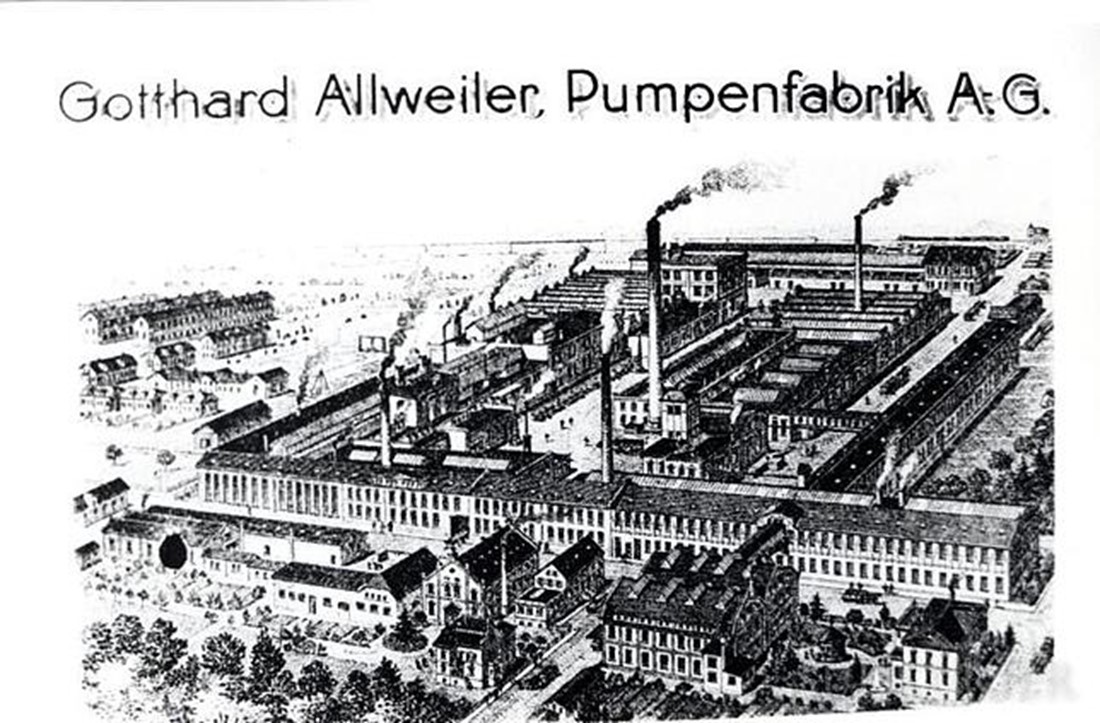

Allweiler GmbH

Radolfzell, Germany

At Allweiler, we are proud of our long history of tradition and success. Founded in 1860, we are Germany's oldest pump manufacturer and recognised worldwide for our first-class quality. As an important part of the CIRCOR Group, we are deeply rooted but globally positioned.

The Radolfzell site has always played a central role in our history. Over the years, Radolfzell has become a leading centre for the development and production of high quality pumps. A key advantage of the site is our in-house foundry, which enables us to produce components with exceptional precision and flexibility to meet our customers' requirements.

| 1860 | 1876 | 1884 | 1905 |

|

|

|

|

|

|

|

|

| 1952 | 1964 | 1995 | 2005 |

|

|

|

|

|

|

|

|

| 2009 | 2010 | 2017 | 2020 |

|

|

|

|

|

|

|

|

| 2023 |

|

|

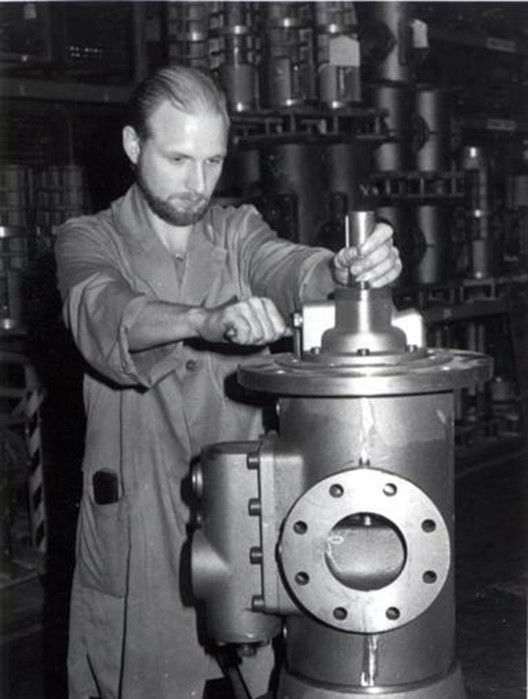

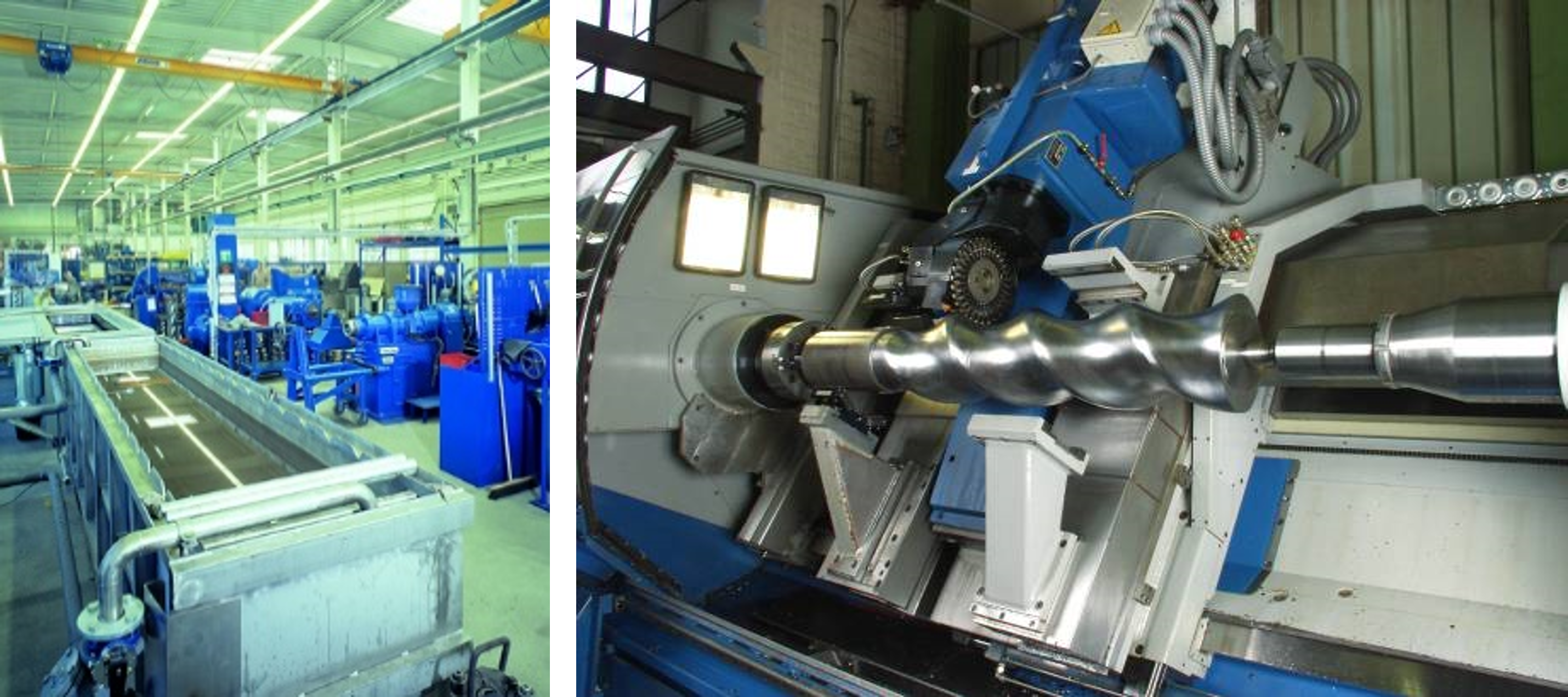

Allweiler GmbH's Radolfzell site is the largest production facility in the CIRCOR Group. State-of-the-art screw, propeller and centrifugal pumps are manufactured here, which work tirelessly in numerous systems and critical applications worldwide.

Pumps are invisible performers that make a great contribution to essential areas of your daily lives.

They ensure that ships sail safely on the oceans, that raw materials are transported reliably in the energy supply, and that clean water is treated efficiently. The precision and reliability of pump technologies impact society in many ways. That's why we at Allweiler are proud to offer such a wide portolio of pumps.

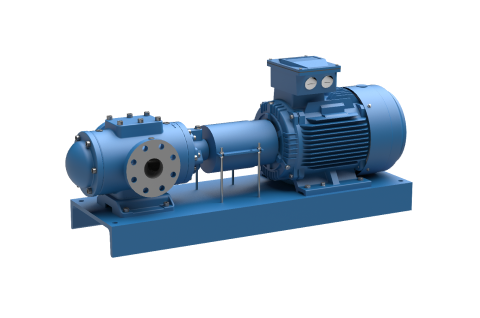

Three-Screw Pumps

Our three-screw pumps provide exceptional efficiency in pumping high-viscosity fluids, even those with low solids content. These pumps provide a reliable, consistent supply of lube and hydraulic oil, making them indispensable in demanding applications.

Centrifugal Pumps

Our centrifugal pumps are true all-rounders, used wherever efficiency and reliability are required. Their versatility and durability ensure that critical processes in many industries run reliably and sustainably.

Propeller Pumps

In Radolfzell, Germany, we manufacture propeller pumps that are specially designed to move large flows reliably, even under the most demanding conditions. Whether in shipping, water management or industry, our pumps are efficient and reliable.

Own Foundry

Crafting Tailored Solutions

For decades, our foundry in Radolfzell has been at the heart of Allweiler’s pump production. By having everything under one roof -from sourcing raw materials to crafting the final component - we ensure that every part meets the highest quality standards. This close control over the process means we’re not just meeting customer specifications, but actively collaborating to create the exact solutions they need, every time.

Job Offers

At Allweiler, we not only get our pumps running, but also your career!

Whether you are just starting out in your career or are already an experienced manager - we will do everything we can to promote your talents and invest in your professional future.

With us, you can expect a dynamic, international environment in which innovation is lived and where you can actively shape the future of the pump industry. Become part of our global team and get your career moving with us!

Explore Open Positions

Your talent is the motor - we make sure you get off to the right start!

Whether it's an apprenticeship or dual study program, technical or business administration - at Allweiler you can expect a wide variety of tasks and exciting opportunities to further develop your strengths.

As a market leader in the pump industry, we offer you an exciting start to your professional future. Become part of our team and learn more about the diverse pump industry. Our experienced trainers will accompany you on your way to a successful career.

Curious? Find out more about why you should do your apprenticeship or studies with us.

ALLWEILER pumps merge tradition and innovation.

More than 150 years of experience, the most advanced technologies, optimally adapted materials and a certified quality management system are the foundations of ALLWEILER's success.

All plants, and the foundry, are certified according to:

DIN EN ISO 9001

Certificates:

The Radolfzell plant, and the foundry, are certified according to:

DIN 14001

Environmental policy

ALLWEILER's executive board defines the basic elements of the company's environmental policy and objectives. The executive board is committed to working with the UMB to make sure that this policy is understood and implemented in every area of Allweiler's Radolfzell plant. Compliance with legal requirements and restrictions is a natural part of our business.

Environmental guidelines at the ALLWEILER GmbH Radolfzell plant

ALLWEILER will contribute to environmental protection, sustainable economies and, therefore, to the preservation of the natural foundations of human life by employing environmentally-friendly technologies and practicing production methods that conserve resources with the help of these technologies. ALLWEILER provides worldwide access to advanced environmentally-efficient technologies and applies them throughout the entire lifecycle of its products. We are committed to achieving continuous improvement in these areas.

ALLWEILER's pump technology contributes to elevated industrial productivity and improved living standards that result in increased productivity.

ALLWEILER principles

- Beyond compliance with environmental legislation and regulations, we work continuously to reduce our environmental impact and consumption of energy and resources.

- Every employee is required to act in an environmentally-conscious manner. Awareness of environmental responsibility is expanded and promoted at all levels of the company and is a permanent responsibility of the company's leadership.

- We ensure that our environmental policy is implemented effectively. The technical and organizational processes necessary for this are checked on a regular basis and continuously improved.

- We appeal to our business partners to employ environmental guidelines that are equal to our own. We work cooperatively with the responsible authorities.

- We inform the interested public about our company's impact on the environment and our environment-related actions. We seek an open dialog with the public in order to receive information about how to improve the situation.

- We support our customers in the environmentally-compatible use of our products.

- ALLWEILER provides the resources needed to implement our environmental policies.

The ALLWEILER environmental policy is applicable to the ALLWEILER GmbH Radolfzell plant as a whole. All employees of the company are called upon to act in accordance with the principles defined in the environmental policy.

ATEX Compliance

EU directive 94/9/EC - ATEX 100a

The implementation of the EU directive 94/9/EC (known under the title "ATEX 100a") is changing the legal basis of explosion protection.

The major changes are:

- Establishment of basic safety requirements for potentially explosive areas

- Non-electric devices and protective systems are included for the first time

- Descriptions of applicable conformity evaluation processes

Publications on this subject:

| Chemie Technik 4/2003 |

Chemie Technik 4/2003: |

| Chemie Technik 5/2003 |

Chemie Technik 5/2003: |

| Chemie Produktion 5/2003 |

Chemie Produktion 5/2003: |

Observance of the new directive is obligatory as of July 1, 2003.

Accordingly, machines that do not fulfill the requirements of the 94/9/EC directive may no longer be operated in potentially explosive environments.

According to the previous legislation, when a pump unit was operated in a potentially explosive environment, only the e-motor was required to comply with the applicable directive 76/117/ EWC. However, the new legislation now specifies that a system's (such as a pump's) mechanical element must also be constructed in accordance with the 94/9/EC directive. ALLWEILER confirms compliance by means of a declaration of conformity.

Important note:

Our pumps were already used in potentially explosive environments before appearance of the directive. Therefore, it is important to note that older units do not require "recertification." The directive applies only to devices that are recently placed into circulation, specifically on or after July 1, 2003.

Since the directive addresses both the date on which the device was placed into circulation and also the date of commissioning (start-up), it is directed at both manufacturers and importers of devices and protective systems. Secondly, however, the directive also affects system operators because they use these devices and are responsible for proper operation.

Since the new 94/9/EC directive went info effect, manufacturers of explosion-protected devices and the users of these devices have assumed new responsibilities.

As a pump manufacturer, ALLWEILER provides you with all the information you will need to operate our pumps in a potentially explosive environment. This includes information about start-up, safe pump operation, maintenance and rapid removal of faults.

As a responsible operator, it is essential that you install, operate and maintain the pump in accordance with the operating instructions.

In addition, the 1999/92/EC directive on minimum guidelines for improving health protection and the safety of workers who could be endangered by potentially explosive atmospheres (fifteenth individual directive in terms of article 16 paragraph 1 of the directive 89/391/EWC) is also relevant for the operator.

Manufacturers of devices intended for use in potentially explosive environments must complete an internal conformity-evaluation process. This analysis is based upon a hazards analysis of the device's mechanical elements. All detectable hazards that could arise from operating the device in a potentially explosive environment are listed together with frequency estimates for each hazard. Measures to minimize the potential of the hazards are derived from this analysis.

In addition, ALLWEILER has subjected its products to a voluntary product-certification program conducted by TÜV Product Service GmbH, Ridler Str. 65, D-80339 Munich, Germany!

The text of the directive 94/9/EC can be downloaded at:

http://europa.eu.int/comm/enterprise/atex/direct/newapproach.htm

EUROPUMP guideline available in English at:

http://www.europump.org/atex_guideline.pdf

Allweiler GmbH, Radolfzell, Germany

Terms & Conditions

Allweiler GmbH, Radolfzell, Germany

Service Portal

The ALLWEILER Service-Portal gives our partners and customers around-the-clock access to important technical information.

At the ALLWEILER Service-Portal you will find:

-

Technical documentation

-

Brochures

-

Operating instructions

-

2D and 3D CAD files and much more